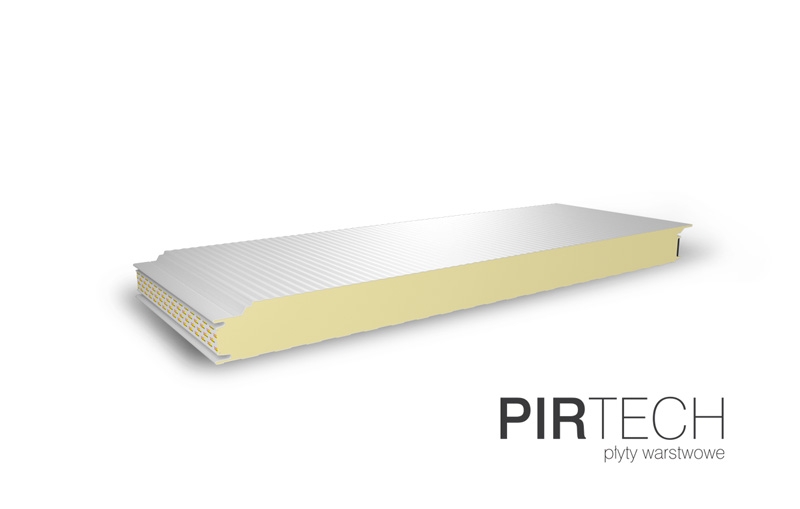

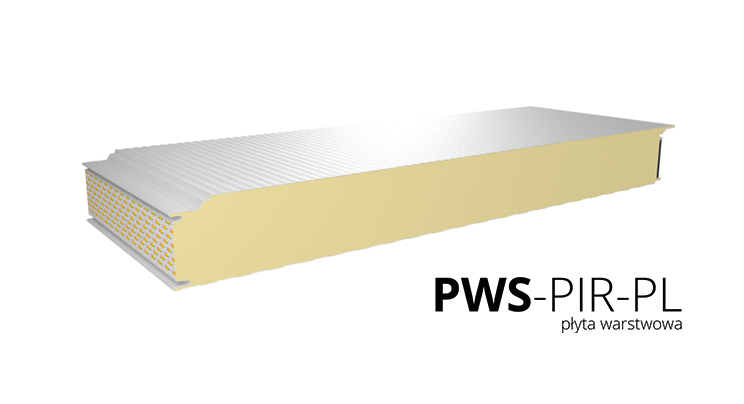

Panel with covered fastening PWS-PIR-PL-60

The elevtion made of this type of slabs gives the impression of a smooth surface (no visible connectors), thanks to which they are often used not only in industrial facilities.

Pruszyński Company guarantess realization of each order in one colour shade. Although due to technological process of covering paint to steel shets there is possibility for occuring difference in colour shade in different deliveries.

Regarding this please inform sales person if different delivery is continuation of previous orders.

In order to ensure color consistency of sandwich panels with other elements such as flashings, they should it ordered from one supplier.

* 1050 mm - standard module, 1000 mm - non -standard module

** Approximate mass masses are given for the thickness of the external sheets. 0.50mm and internal 0.40mm and standard module.

Allowed length of panels depending on colour of cladding (minimal length - 2,5 m) for single-span scheme.

13,5 m

12 m

9 m

During projecting it’s important to include difference in temperature of external and internal cladding of sandwich panels. Gradients of temperatues due to difference in external temperature T1 and internal temperature T2 are dependent on few factors:

Purpose of building (range of temperatures inside building T2)

localization of building – position due to sun

colour of external steel cladding (T1).

Depending on latitude, height above sea level and distance from sea on europe continent are use 4 different levels of winter temperature (T1 – external cladding):

0, -10oC,

0, -20oC, (for ex. Poland)

0, -30oC, (for ex. scandinavian countries)

Temperatures of external cladding of roof panel which is covered with snow layer is 0oC.

For calculation was assumed external temperature in winter of -20 oC.

Temperature of external cladding T1 has maximum value during summer and is depending of colour and grade of reflection of surface. Values T1, which are minmal for calculation bearing status (SGN) and are proper for calculations of limit status of use (SGU) are:

where RG – grade of reflextion in ratio of magnesium oxide = 100%

Recommended ways of transport for sandwich panels:

Sandwich panels should be storage maximum 2 packages one on another.

In below chart you can see what is maximal quantity of panels in one package.

| thickness of panels | PWS-PIR-PL |

|---|---|

| 60 mm | 18 pcs. |

| 80 mm | 14 pcs. |

| 100 mm | 11 pcs. |

| 120 mm | 9 pcs. |

ATTENTION !!!

All packages should be storage on flat surface with possibility to discharging water.

In case of panels with visible fix(PIR-ST), upper side of package is elevation side, which is very important.

ATTENTION!

The Pruszyński Group has been supporting Polish volleyball for over 15 years and it is undoubtedly […]

Read morePlease be advised that on 01/03/2023 the Fincostal brand will be fully connected to Pruszyński sheet. Considering the interests of our contractors and clients, we took steps for this process to take place maximally smoothly, without any impact on the continuity of the offer and conditions.

Read moreThe beginning of the year is full of unique industry meetings. After Dachforum 2023, which turned out to be a huge success, time for Budma, i.e. the largest event of the construction industry.

Read more