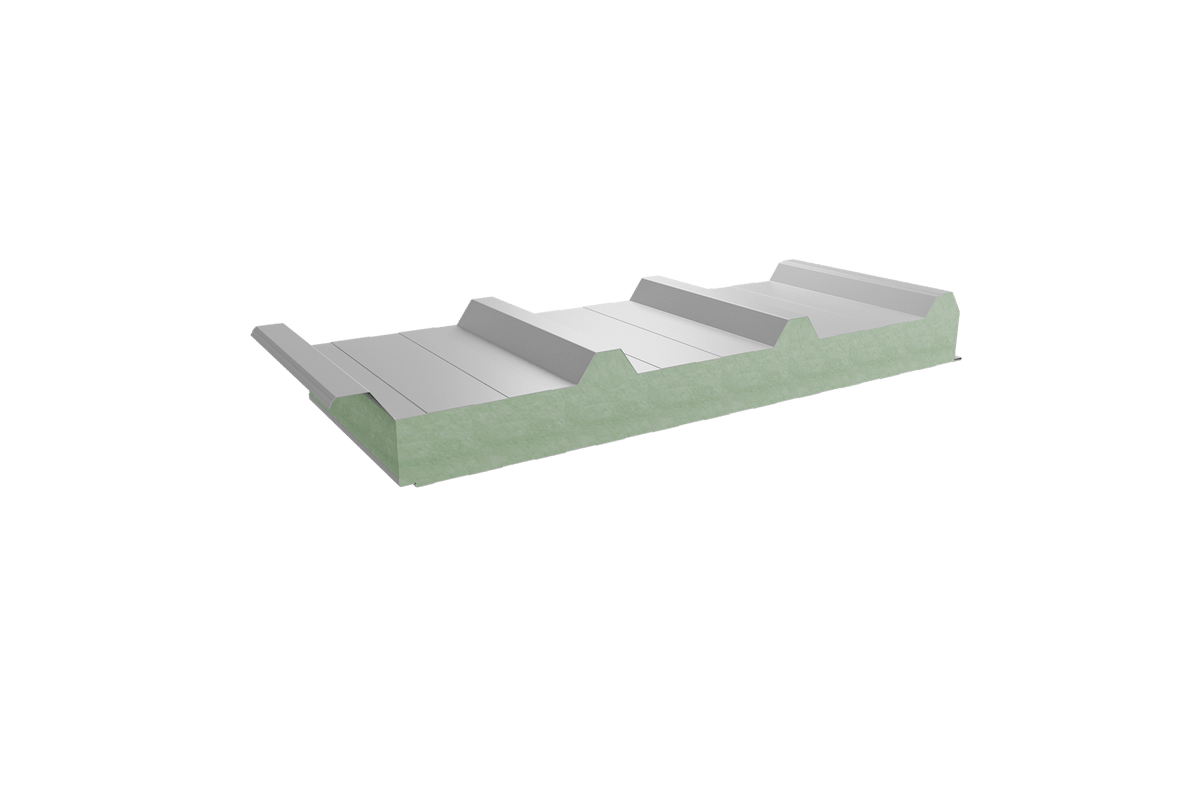

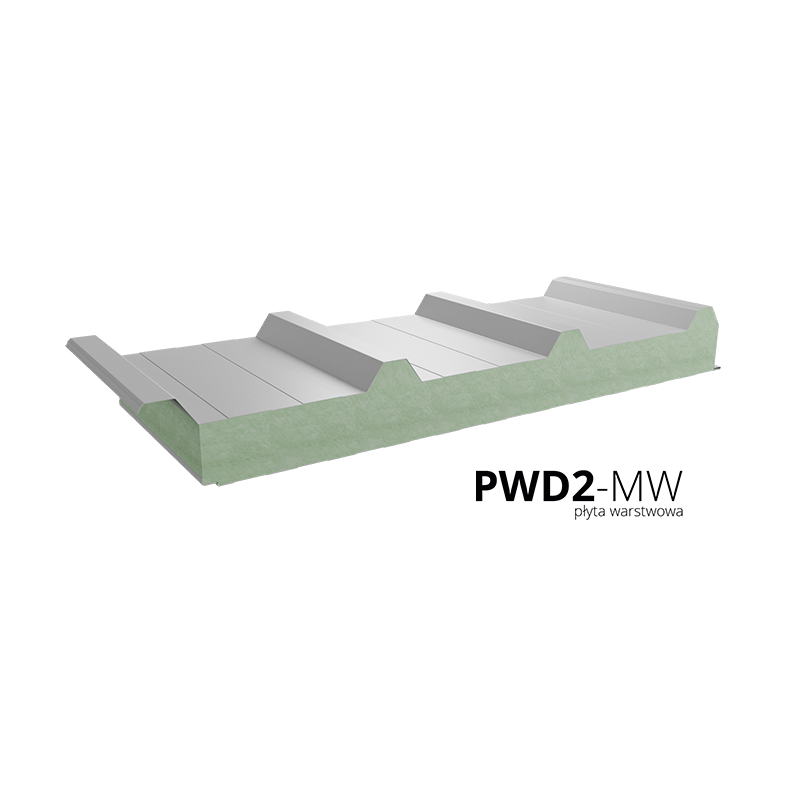

Sandwich panel - mineral wool core, density 115 kg/m<sub>3</sub> thickness 100 mm

Roof sandwich panels are used especially in hall, industrial and public buildings (shopping centers, warehouse centers, sports halls, etc.). Roof sandwich panels are basically used only as roof coverings, where they fulfill their function perfectly.

The rich color palette and various shapes of the panels’ profiles enable the creation of a number of interesting objects. Roof sandwich panels with a wool core offer exceptional fire resistance parameters and very high acoustic insulation parameters

Wyrób budowalny PWD-MW montowany z najlepszych materiałów na najnowocześniejszej w Europie linii produkcyjnej przeznaczonej dla tego typu produktów

The roof sandwich panel with a mineral wool core (WOOLTECH Dach), manufactured by Blacha Pruszyński, is manufactured on a modern production line, maintaining the highest quality standards. It is a roof panel with a wool core of the second generation, ensuring very high thermal insulation parameters with excellent fire properties at the same time. The mineral wool core is placed between two galvanized, coated sheet metal claddings. Our offer includes various types of coatings and colors to choose from, as well as core thicknesses from 100 to 240 mm. The roof profile of the external cladding (trapezoidal, 40 mm high) ensures very good water drainage parameters.

Depending on the method of installation of the panels, the recommended minimum roof slopes are:

* for roofs made of continuous panels (without cross-connection along the length)

** for roofs made of panels connected crosswise along the length

*** flat internal profiling (P), available only for sheet thicknesses above 0.6 mm

The table below contains a classification divided into color groups for individual colors available in the Pruszyński Sp. z o. o. Permissible board lengths depending on the color of the cladding (minimum length - 2.5 m) for single-span systems.

16 m wall / 16 m roof

12 m wall / 16 m roof

9 m wall / 13,5 m roof

NOTE – group III – dark colors

Taking into account that dark colors from Group III are subject to much greater thermal loads than very light and light colors from groups I and II, special attention should be paid when designing to ensure that the following conditions are met:

the mounting method and static system must comply with the tables of permissible loads and spans (criteria met – ultimate limit state, serviceability limit state)*

limit the maximum length of boards according to the manufacturer’s recommendations**

take into account the installation temperature***

* Single-span systems are recommended for dark-colored panels; otherwise, deformations of the outer slab cladding may occur on the intermediate supports and are unacceptable to the Investor. The corrugations in question meet the requirements of the PN EN 14509 standard in terms of permissible deviations, however, they may cause complaints.

** Maximum board lengths should be in accordance with the manufacturer’s guidelines depending on the type of board and their application (roof/wall) – see BOARD LENGTHS. At the customer’s request and after signing the declaration, it is possible to deliver roof panels in Group III colors, 16 m long.

*** Installation of dark colored boards is possible at temperatures from 10oC to 35oC. This condition must be strictly observed. Installation at temperatures lower than 10oC (or higher than 35oC) may lead to deformation and permanent damage of the board during the use of the building (in extreme cases also during installation). In this case, deformations and damage to the board are caused by the high elongation of the linings (e.g. at summer temperatures) in relation to the initial length (length of the lining during installation).

Installation of boards in light and very light colors is possible in the temperature range from +5oC to +35oC.

Failure to comply with the above guidelines may result in surface deformations on the boards and local loss of stability, for which the manufacturer is not responsible. In the case of colors not included in the table, please contact Pruszyński’s technical advisor. The color of the board may be changed only with the designer’s consent.

Recommended means of transport for sandwich panels:

Sandwich panels should be stored in packages (posts), a maximum of two packages can be stored on top of each other.

The table below shows the max. number of boards that can be arranged in one package.

| panel thickness | PWD2-MW |

| 100 mm | 10 items |

| 120 mm | 8 items |

| 140 mm | 6 items |

| 150 mm | 6 items |

| 160 mm | 6 items |

| 180 mm | 6 items |

| 200 mm | 4 items |

| 220 mm | 4 items |

| 230 mm | 4 items |

| 240 mm | 4 items |

| 250 mm | 4 items |

In order to extend the durability of roofs and facades made of coated sheet metal, they should be regularly inspected and maintained.

The company Pruszyński Sp. z o. o. is not responsible for any accidents resulting from the above activities.