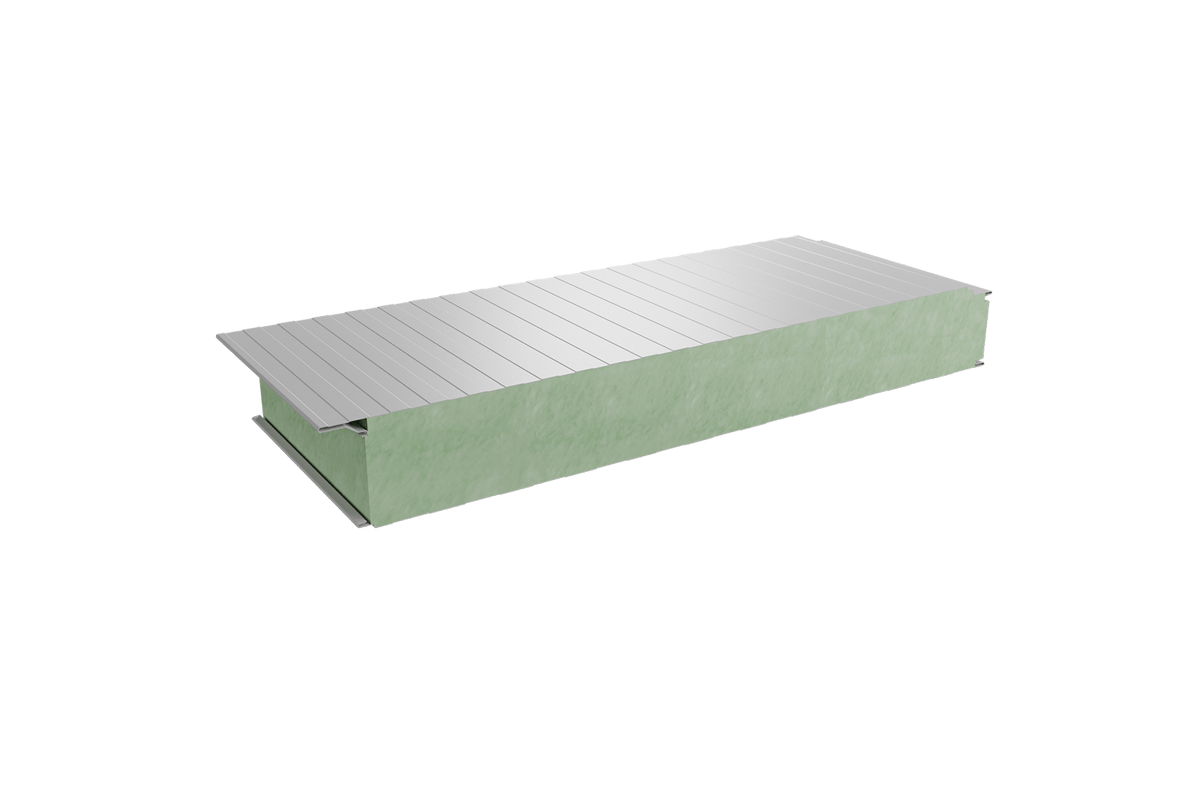

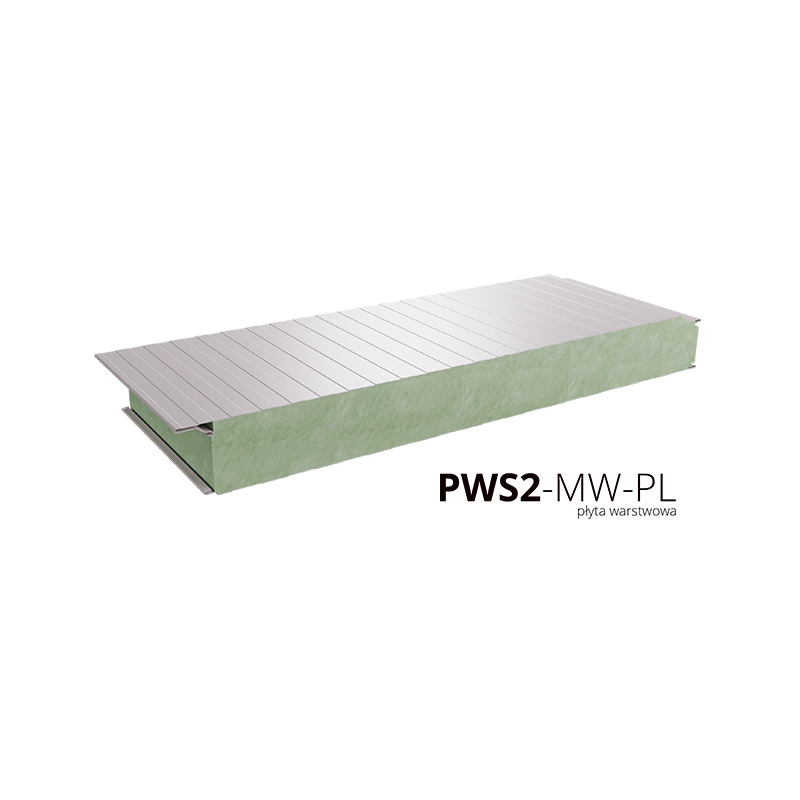

A wall plate with a core of mineral wool (PWS2-MW) is another, much more advanced generation of this product. Along with the introduction of a new generation, we have also expanded the product range available to customers, with a hidden lockboard (PWS2-MW-PL). What is very important, the new variant has been designed specifically for synergy with our other products, including a core with polyurethane foam core (PWS-PIR-ST, PWS-PIR-PL).

The use of dedicated hidden lock solutions as well as parameters allows you to easily combine both products on investments, giving greater flexibility in design and also achieving the desired physical parameters in specific segments of the building.

* Flat outer profiling (P), available only from the thickness of sheet metal above 0.6 mm

The basic technical and physical parameters of the product can be found in the tables and combinations below. In order to familiarize yourself with the values of our products, please contact us directly at the email address: inwestycje@pruszynski.eu

In terms of approvals and certificates – full documentation is in the download section

| Thermal trasmittance value – Uc (W/m2K) | 0,29 |

| Fire resistance | EI60 (o↔i) (vert 7,5m)EI90 (o↔i) (pion 6,0m) |

| Flame propagation by wall/ reaction to fire | NRO / A2-s1, d0 |

| Airborne sound insulation (dB) | Rw30 |

| Sound absorption (αw) | NPD |

Recommendations for the selection of plates in the context of thermal loads

When designing, the temperature differences between layered panel cladding should be taken into account. Temperature gradients resulting from the temperature difference between the T1 outer temperature and the T2 internal temperature depend on several factors:

the purpose of the object (temperature range inside the object – T2)

facility location – location relative to the sun

The color of the outer cladding (T1).

Depending on the latitude, height above sea level and distance from the sea on the European continent, four different levels of winter temperature (T1 – outer cladding) are used:

0, -10°C,

0, -20°C, (e.g. Poland)

0, -30°C, (e.g. Scandinavian countries)

The temperature of the external cladding for roof plates covered with a snow cover layer is 0°C.

The external temperature during the winter -20 °C was adopted for calculations.

The temperature of the T1 outer cladding has a maximum value in the summer and it depends on the color and degree of surface reflection. T1 values, which are minimal for calculations of the load capacity (SGN) and suitable for calculations of the limit state of use (SGU), are as follows:

where RG- is the degree of reflection of the radius in relation to magnesium oxide = 100%

The table below has a classification divided into color groups for individual colors available in the assortment of Pruszyński Sp. z o.o.

The table below has a classification divided into color groups for individual colors available in the assortment of Pruszyński Sp. z o.o permissible panel lengths depending on the color of the cladding (minimum length - 2.5 MB) for single -span systems.

16 m wall / 16 m roof

12 m wall / 12 m roof

9 m wall / 9 m roof

ATTENTION- III group – dark colours

Taking in consideration that dark colours from group III has much bigger thermal load and very bright and bright colours from groups I and II, there should be paid special attention during projecting and below conditions are complained:

* For panels with dark colours recommended are single-span schemes; in other case there may occur non-acceptable by Investor strains on external claddings on panels on intermediate supports. Flutings which may occur, complain with norm PN EN 14509 due to acceptable deviation, but may be topic of complaints.

** Maximum length of panels should be in accordance of producer’s guidelines due to type and use of panels – see LENGTH OF PANELS

*** Assembly of panels with dark colours is possible within temperatures 10oC to 35oC. This condition is essential and must be strictly observed.

Assembly of panels in very bright and bright colours is possible within range of temperatures from +5oC to +35oC

Recommended means of transport for sandwich panels:

Layered boards should be stored in packages (posts), it is allowed to store a maximum of two packages one on top of

The following table is given max. The number of discs that can be arranged in one package.

| Panel thickness | PWS |

| 60 mm | 18 pcs |

| 80 mm | 14 pcs |

| 100 mm | 11 pcs |

| 120 mm | 9 pcs |

| 140 mm | 8 pcs |

| 160 mm | 7 pcs |

| 180 mm | 6 pcs |

| 200 mm | 5 pcs |

| 220 mm | 5 pcs |

| 240 mm | 4 pcs |

| 260 mm | 4 pcs |

ATTENTION !!!

In the case of wall panels with visible fastening, the upper side of the panels in the package is a facade side, which should be paid special attention!

In order to extend the durability period of roofs and facades made of coated sheets, they should be regularly controlled and preserved.

Pruszyński Sp. z o.o. He is not responsible for any accidents arising from the above -mentioned activities.

The Pruszyński Group has been supporting Polish volleyball for over 15 years and it is undoubtedly […]

Read morePlease be advised that on 01/03/2023 the Fincostal brand will be fully connected to Pruszyński sheet. Considering the interests of our contractors and clients, we took steps for this process to take place maximally smoothly, without any impact on the continuity of the offer and conditions.

Read moreThe beginning of the year is full of unique industry meetings. After Dachforum 2023, which turned out to be a huge success, time for Budma, i.e. the largest event of the construction industry.

Read more