Currently, it is difficult to imagine construction, especially indoor public utilities, industrial and agricultural (storage, cold stores, freezing, farm animals) without housing (cover walls, roofs) in the form of sandwich panels, especially from plates in metal cladding.

Light layered plates are constructions made up of rational and properly connected structural and insulation and construction materials. They consist of external layers (cladding) with high mechanical properties in a continuous way connected to the central layer (core) with negligible flexible rigidity, but with favorable thermal insulation.

Apart from cover walls and covering, sandwich panels are used as:

Such a wide range of use results from their advantages, which include:

One of the items that are very popular in the commercial offer of Pruszyński Sp. z o. o. are wall and roof layered panels with a core made of rigid polyurethane foam in metal cladding. Responding to the market interest and growing demand, we also introduced the second generation of sandwich panels with a core of mineral wool – PWS2. This latest item in our offer already has a large group of loyal customers that are constantly growing. Hence, we plan to further expand the types of assortments in this category of layer plates. Currently, standard density (ST) and discs with reduced vague and weight are available in the offer.

Wall panels with a maximum modular width of 1150 mm (visible fastening) and 1050 mm (hidden mounting and roof plate) allow you to simple and quick installation to various types of structures using appropriate cruising fasteners. The uniquely designed longitudinal contacts (locks) of the pen and wpust ensure very good tightness, fire resistance and quick assembly.

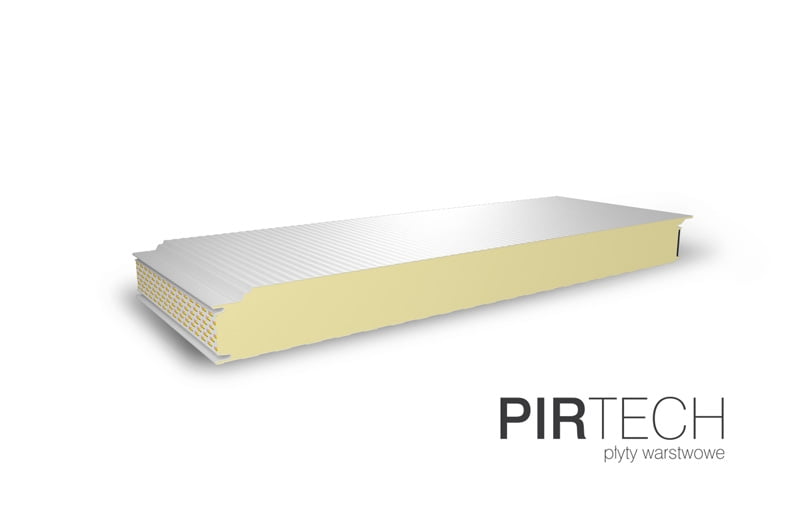

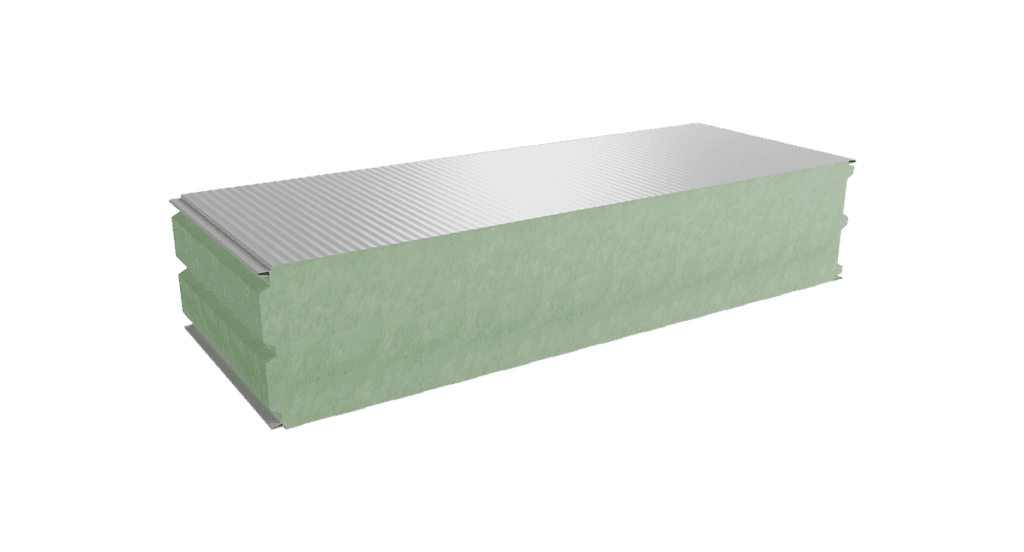

PIRTECH wall panels, standard joint (visible joint) with a maximum modular width of 1150 mm allow for simple and quick installation to various types of structures using appropriate through fasteners. The uniquely designed longitudinal connectors (joints) of the fold and rabbet, ensure very good tightness, fire resistance and quick assembly.

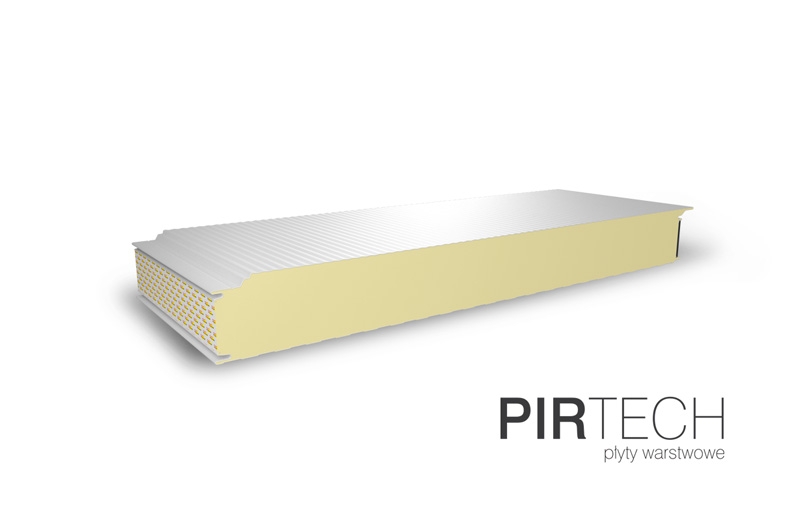

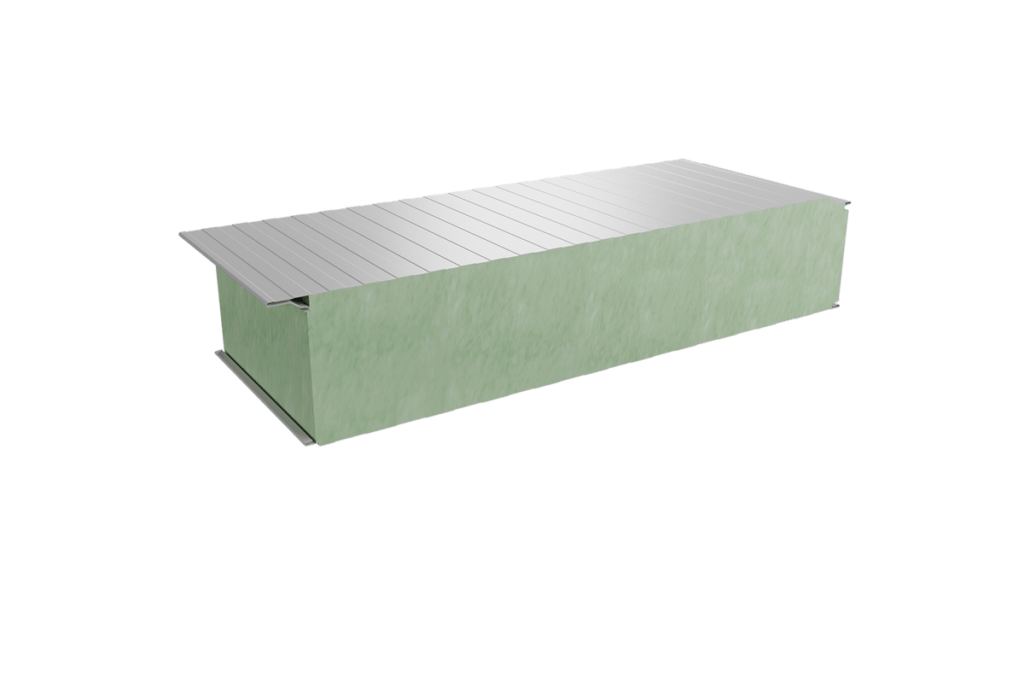

PIRTECH Plus wall panels (hidden mounting) with a maximum modular width of 1050 mm allow for simple and quick installation to various types of structures using appropriate through fasteners. They work similarly to PIRTECH Standard however the joint is hidden under specially designed ply made at the end of sandwich. This allows to hide the connection between the panels assuring smooth and seamless design of the elevation.

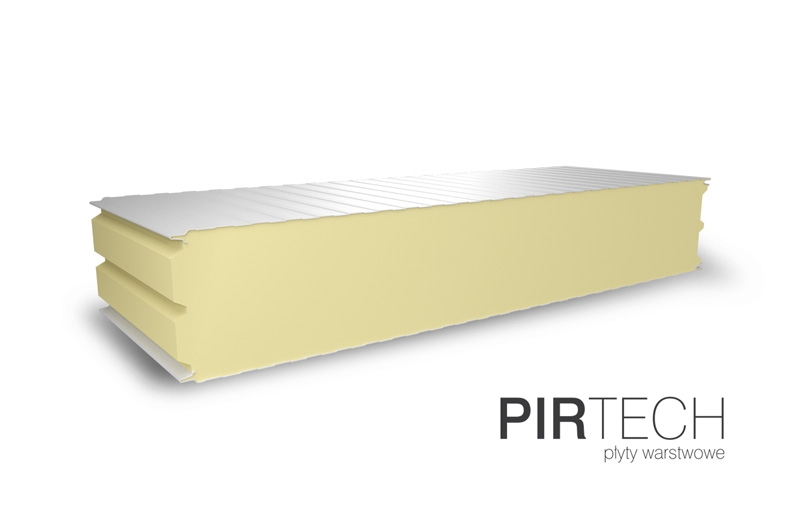

PIRTECH Cold storage is another wall panels variant (visible joint) with a maximum modular width of 1150 mm. The core is particularly dense and thick providing best thermal insulation needed for cold storages and other industrial buildings of similar type. Fully compatible with other PIRTECH variants, Cold storage, share similar technical solutions – simple and quick installation to various types of structures using appropriate through fasteners, as well as the highest product quality.

PIRTECH wall panels Plus wall (hidden mounting) with a maximum modular width of 1050 mm allow for simple and quick installation to various types of structures using appropriate through fasteners.

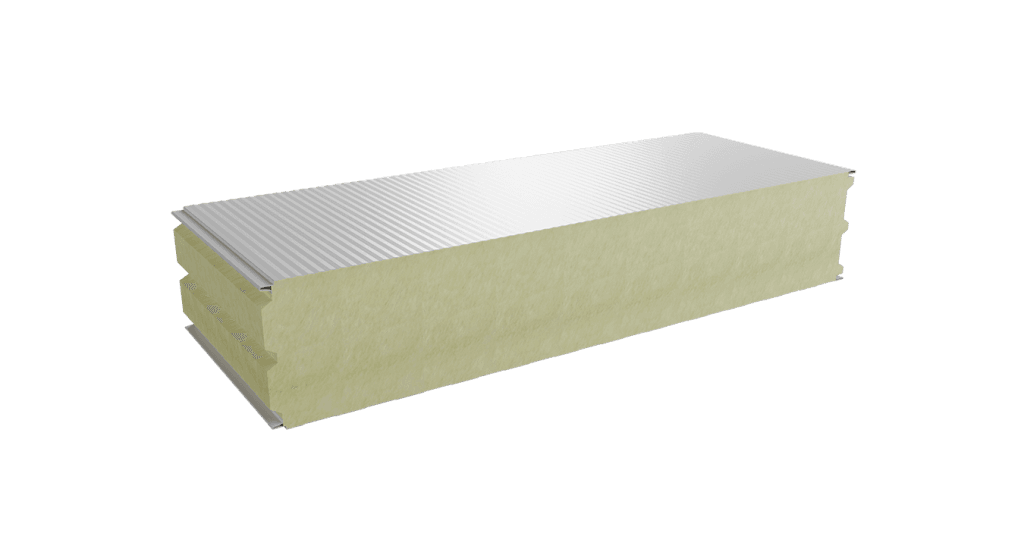

Wall layered sandwich panels are used especially in indoor, industrial and public construction (shopping centers, warehouse centers, sports halls, etc.). Core made of mineral wool of the highest quality providing best fire resistance parameters.

WOOLTECH wall panels Plus wall (hidden mounting) with a maximum modular width of 1050 mm allow for simple and quick installation to various types of structures using appropriate through fasteners. Core made of mineral wool of the highest quality providing best fire resistance parameters.

WOOLTECH wall panels EKO (visible joint) with a maximum modular width of 1150 mm allow for simple and quick installation to various types of structures using appropriate through fasteners. Core made of mineral wool of lower density (~ 80kg/m3) which helps to achive much lower mass per cubic meter and hence installation on girders with bigger span.

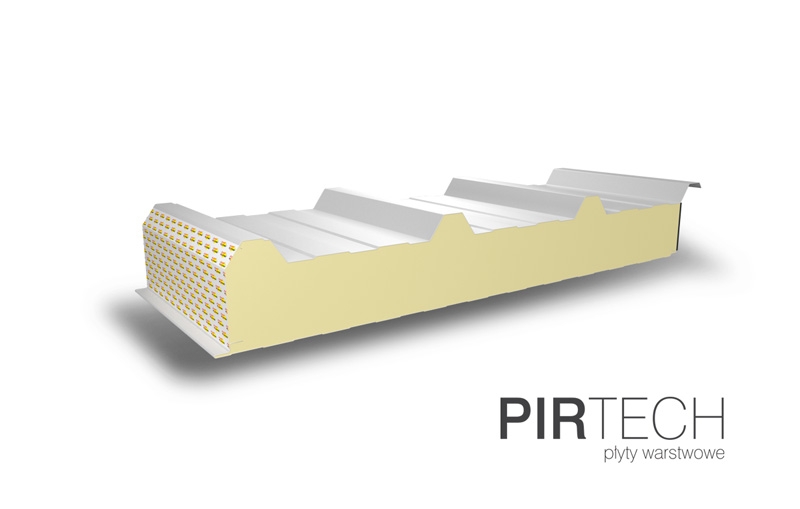

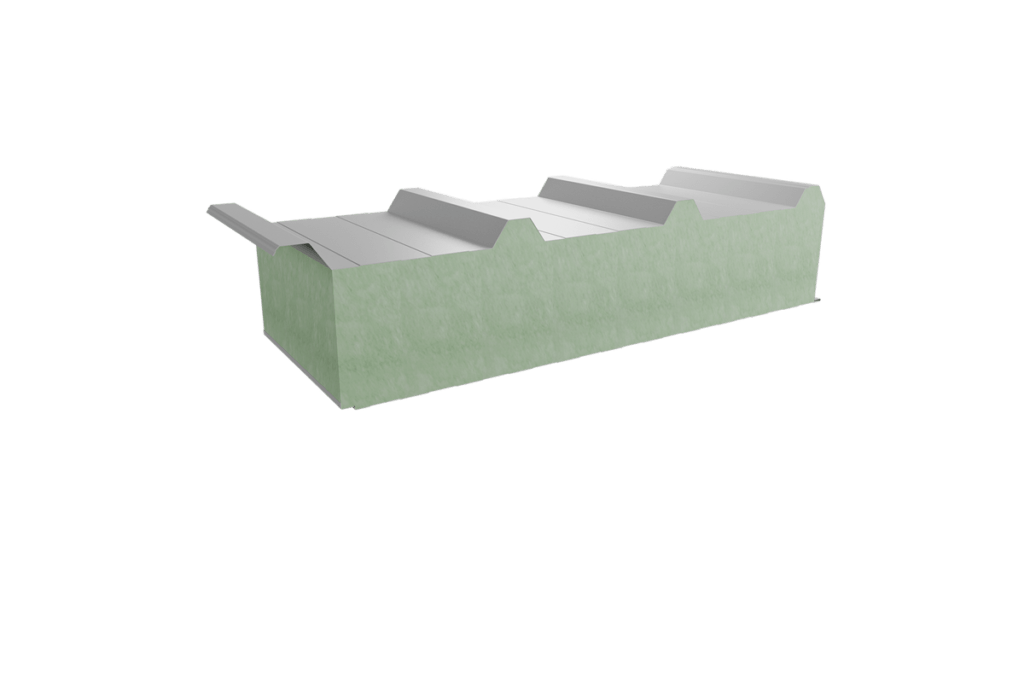

WOOLTECH roof panels (hidden mounting) with a maximum modular width of up to 1050 mm. External profiling – trapeze to provide much higher stiffness as well as bearing capacity. Additionally profiling helps to lead off the rain water to drainage system. Possible thickness of the panels up to 250 mm

The layered plate system with stiff pirtech polyurethane foam in metal cladding of Blacha Pruszyński includes:

* for roof plates connected continuously, without skylights

** for roof slabs connected transversely in length or with skylights

The layer plate system with a core of mineral wool in metal cladding productions from Blacha Pruszyński includes:

* for roof plates connected continuously, without skylights

** for roof slabs connected transversely in length or with skylights

*** for external profiling type “flat” (P), recommended thickness of the sheet – 0,6 mm

Wall sandwich panels are a construction product for the walls of building walls such as production halls, warehouses and other commercial and service facilities. Although their main application is industrial and commercial investments, this does not exclude their use by individual clients if they meet the project requirements. An important issue is that sandwich panels are a protection product and not a supportive product. This means that they are mounted to load -bearing elements, thus creating walls.

The key contribution feature of sandwich panels is the combination of tin cladding with a core with a clear thermal insulation or acoustic characteristics, to which the English name also refers: “Sandwich panels”. The core is usually a polyurethane foam (PIR), which guarantees a high thermal insulation coefficient or mineral wool, which has worse thermal insulation parmers, but in turn has higher fire resistance and better acoustic parameters.

In addition, at our disposal, our offer of wall sandwich panels has at their disposal models with a standard lock and with a hidden lock, i.e. plus (marked with the symbol PL). Currently, such a product variant is available in the offer, for a polyurethane core plate -PIRTECH WALL Plus. In the near future we plan to introduce the same solution for a plate with a mineral wool core.

Next to the cover walls, sandwich panels are most often used as an element of roof covering. This use of this product has great advantages. One of the basic is the limitation of heat loss in the building, thanks to the high terminal insulation of sandwich panels. In addition, they provide a relatively simple and automated assembly within the system, which significantly accelerates the building construction process. As in the case of wall panels – the installation of roof plates is the same: tin cladding is connected by a core that ensures high thermal insulation parameters. The main difference between wall and roof plates is different profiling of external cladding. Due to the completely different stress and loads, which are subject to roof sandwich panels, usually the external tin cladding has a high stroke trapezoidal profile, ensuring adequate stiffness, required on the roof.

The Pruszyński Blachy offer includes roof slabs with polyuretnate foam core marked with the symbol PWD-PIR, which have very similar thermodynamic characteristics to wall plates. Going according to the latest trends, we plan to expand our offer of sandwich panels with a woolen core with a roof variant by the end of the year.