Painting coatings used for the production of roof and facade sheets are used to protect the surface of the material against harmful environmental effects and against mechanical damage, as well as for aesthetic purposes, i.e. to give an attractive appearance of the surface. The Pruszyński company offers a rich variety of coatings.

Poliester POŁYSK — PS25

Poliester POŁYSK METALIC — PS25

Up to 30 years of warranty

Polyester coatings are resistant to UV radiation (level in accordance with the RUV4 classification - the most demanding category of the European standard EN 10169/2).

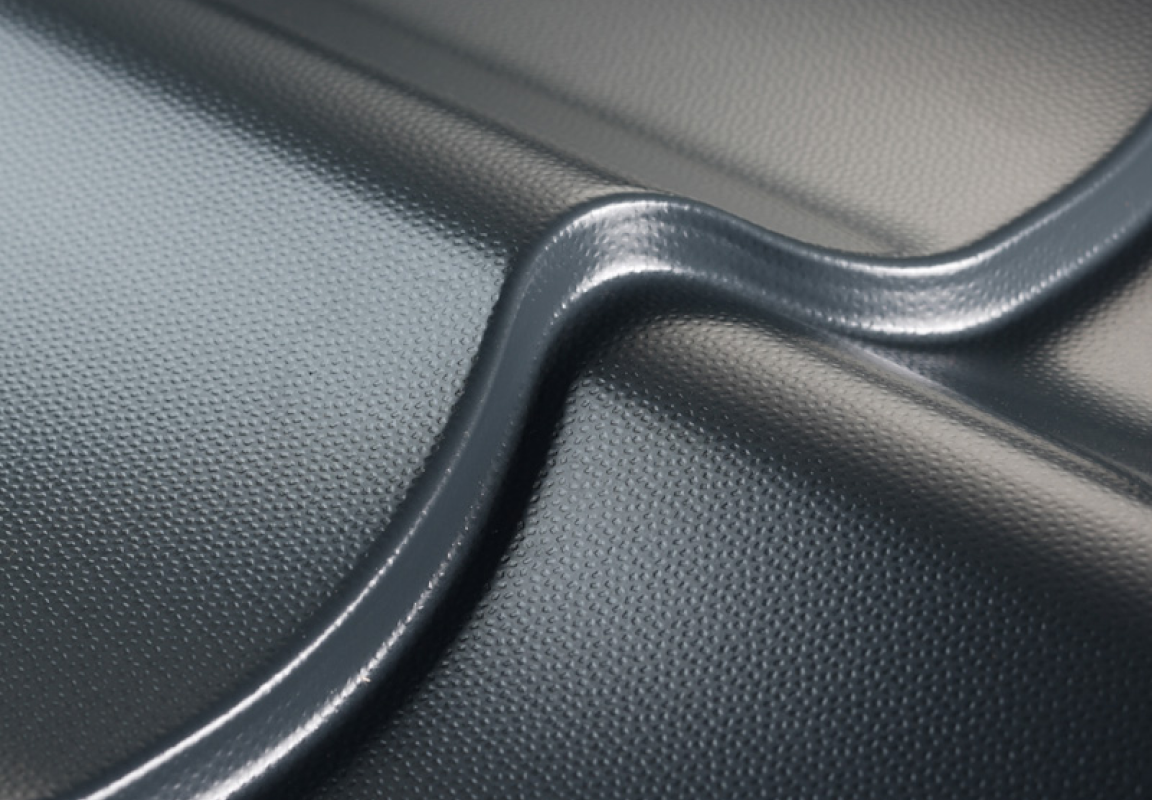

Poliester MAT Gruboziarnisty — PMG35

TOPMAT — 35

Up to 35 years of warranty

Polyester coatings are resistant to UV radiation (level in accordance with the RUV4 classification - the most demanding category of the European standard EN 10169/2).

PURMAX ® — UX40

Up to 40 years of warranty

The Purmax® hybrid coating has been developed for high resistance to environmental conditions and high resistance to mechanical damage. The main protection is the connection (hybrid) of two layers of varnish, polyurethane and polyester. The polyurethane coating is responsible for corrosive resistance, and the upper polyester layer for resistance to UV radiation. This selection and layout of the coatings cause that the product has high resistance to mechanical damage and environmental conditions.

PURLAK ® — PU50

PURMAT ® — PUM50

Up to 50 years of warranty

Polyurethane coatings are very resistant to UV radiation (level in line with the RUV4 classification - the most demanding category of the European standard EN 10169/2). The paints used have exceptional resistance to photochemical aging processes, which makes this product an ideal solution for use in projects in which aesthetic values, strength and durability of color are particularly important.

Colorcoat HPS 200 Ultra ®

Colorcoat PRISMA ®

Up to 40 years of warranty

COLORCOAT series coatings have been developed for particularly difficult conditions of high humidity. Thanks to technologically advanced recovery processes, as well as the unique composition managed to achieve one of the highest standards of anti -corrosive resistance - C5. Such standards are required from products that must be used in extremely demanding circumstances. An example here can be coastal buildings, constantly exposed to a high level of humidity and salt water, as well as industrial buildings, where the sheet will be operated in high humidity conditions, such as swimming pools, processing plants and sewage treatment plants.