The function of smoke curtains (along with other elements) is controlling movement and/or accumulation of smoke and heat. Smoke curtains can accumulate smoke and gases at a temperature exceeding up to 600 degrees Celsius, but they should not be confused with fire separation. Curtains are primarily to prevent free spread of smoke and fire gases in rooms with large surfaces – such as warehouses, halls etc. Due to their important role in the fire protection system, their selection should be the responsible designer of the object who will choose the curtain for their specific use.

Permanent smoke curtains T35KD Production Pruszyński Sp. z o. o. from sheet metal is a permanent element of the gravitational smoke exhaust system. The minimum steel species used for curtains is S280GD. The thickness of the sheets used for smoke curtains is 0.60 mm. Coated sheets on both sides with a polyester organic coating (SP) with a maximum thickness of 35 µm. The maximum height of the curtains is 450 cm.

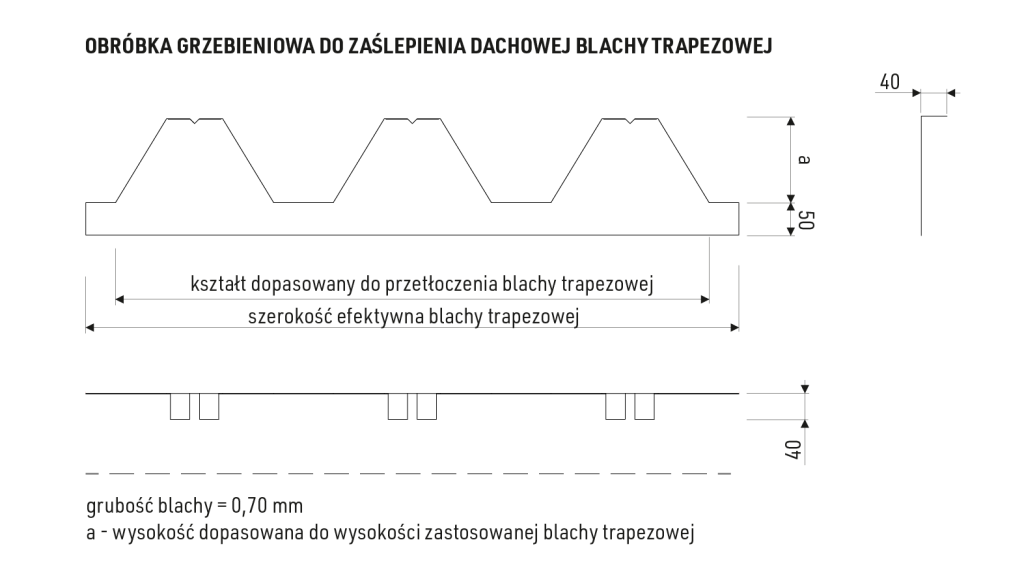

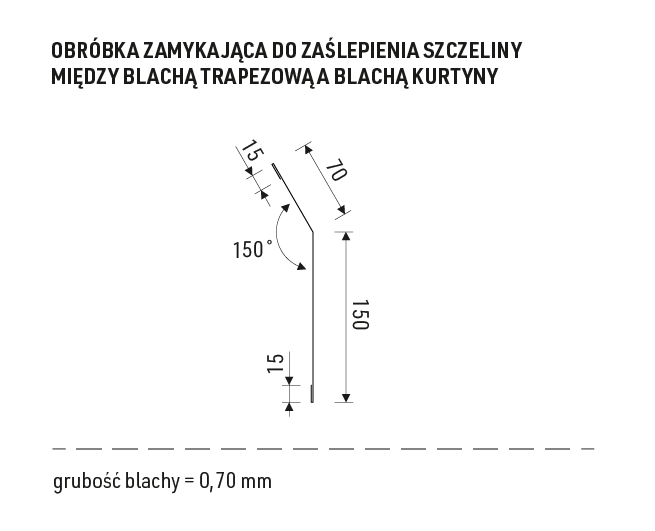

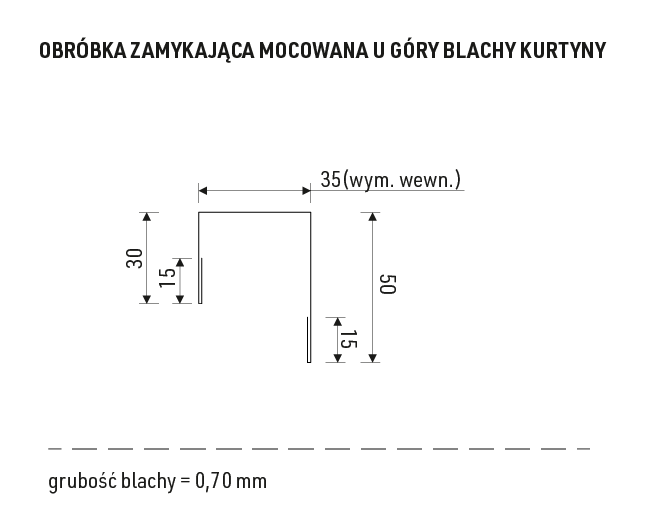

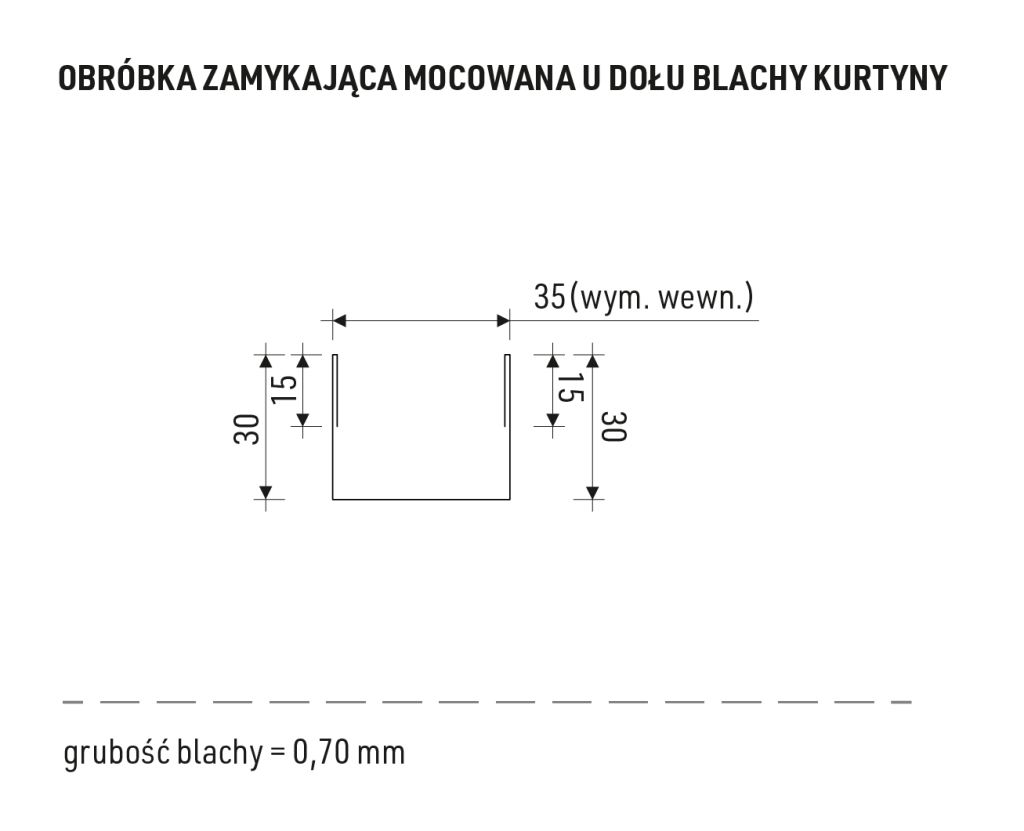

Blachy Pruszyński also offers flashings matching the T35 KD curtain. They are made of the same high -quality sheet as the curtain itself. The basic offer includes 4 machining:

Combing

(is mounted for trapezoidal sheet used in the roof structure. Its dimensions depend on the trapezoidal sheet metal used in a given design)

Closing machining

(roof slot)

Closing machining

(Upper Slite)

Closing machining

(roof slot)

In addition to basic machining, we also offer the possibility of dedicated curtain machining according to the design. In order to read the offer, please contact the Sales Department.

Additional technical drawings of basic machining with a detailed description can be found in the assembly instructions for T35KD: download files

Basic parameters of the T35KD smoke curtains according to PN EN 12101-1

The load from 1mb of the curtain depending on its height is given in the table:

| The height of the curtain [m] | Load [kN/m] |

| 0,50 | 0,028 |

| 1,00 | 0,055 |

| 1,50 | 0,083 |

| 2,00 | 0,110 |

| 2,50 | 0,138 |

| 3,00 | 0,165 |

| 3,50 | 0,193 |

| 4,00 | 0,220 |

| 4,50 | 0,248 |

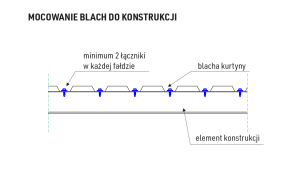

Constant T35KD smoke curtains are attached to the upper edge to the supporting structure with the help of self -controllers. The support structure must have the required fire resistance class, resulting from the fire resistance class of the building. The attachment takes place with a minimum of two connectors, and the sheets forming the curtain are sewn with self -connectors.

The manufacturer’s technical requirements regarding the mounting elements are presented in detail in the T35KD assembly instructions, with the manufacturer allowing the use of connectors with not worse fire and mechanical properties from the recommended ones.

In the event that the entire curtain has a different shape than a rectangle and when the last fastened sheet cannot be installed in full, it is necessary to cut the sheets. For cutting sheets, use electric scissors with a rotating head. After the installation, it is absolutely cleaned of the surface of filings, screws, etc. In the event of damage to the surface, the necessary (point) retouching should be made as soon as possible, using the appropriate varnish with the original color of the sheet metal. When using a grinder, complaints will not be included.

Note: regardless of the manufacturer’s assembly recommendations for the design of the curtain sheet fastening to the structure and the design of the structure itself, to which the curtain is to be fastened, the designer of the object is responsible. Pruszyński Sp. z o.o. It can be supported by designers in the field of technical consultations for a given project.

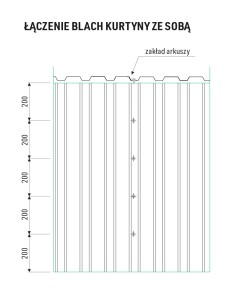

In the case of smoke curtains T35KD Pruszyński sheet production, assembly is based on two stages-sewing sheets between each other and fixing sheets to the structure.

COMMENTS

Examples and detailed descriptions of curtain assembly, along with examples of use, can be found in the assembly instructions for T35KD: download files

A) stitching sheets among themselves

Connect sheets

Type of connector: Self -made connectors WSBP Production Klimas Sp. z o.o. with dimensions: 4.8 x 19 mm from SAE1022 steel

Method of attaching connectors according to the manufacturer’s data

Note: other connectors with not worse fire and mechanical properties are allowed.

B) Fastening sheets to the structure

In the case of receiving its own means of transport, the car should have an open loading platform for free loading and unloading. Galvanized and aluminum sheets must be protected against wetting!

“Manual” unloading should be carried out by the right number of people, i.e. such so as not to move the sheet metal, not bend the side edges and not stretch them. Deformation of sheets during unloading and carrying causes later problems with their proper assembly (gaps on locks, which can cause a curtain leak). The most suitable is unloading in the manufacturer’s packaging using mechanical devices.

The Pruszyński Group has been supporting Polish volleyball for over 15 years and it is undoubtedly […]

Read morePlease be advised that on 01/03/2023 the Fincostal brand will be fully connected to Pruszyński sheet. Considering the interests of our contractors and clients, we took steps for this process to take place maximally smoothly, without any impact on the continuity of the offer and conditions.

Read moreThe beginning of the year is full of unique industry meetings. After Dachforum 2023, which turned out to be a huge success, time for Budma, i.e. the largest event of the construction industry.

Read more