Wall sandwich panels are used especially in indoor, industrial and public construction (shopping centers, warehouse centers, sports halls, etc.). In addition to the cover walls, the plates are used as: partition walls and as load -bearing walls in small transportable cold stores, in buildings of construction and in farm buildings. The rich color palette and the diverse shape of disc profiling enables the implementation of a number of interesting objects. The plates can be mounted both vertically and horizontally.

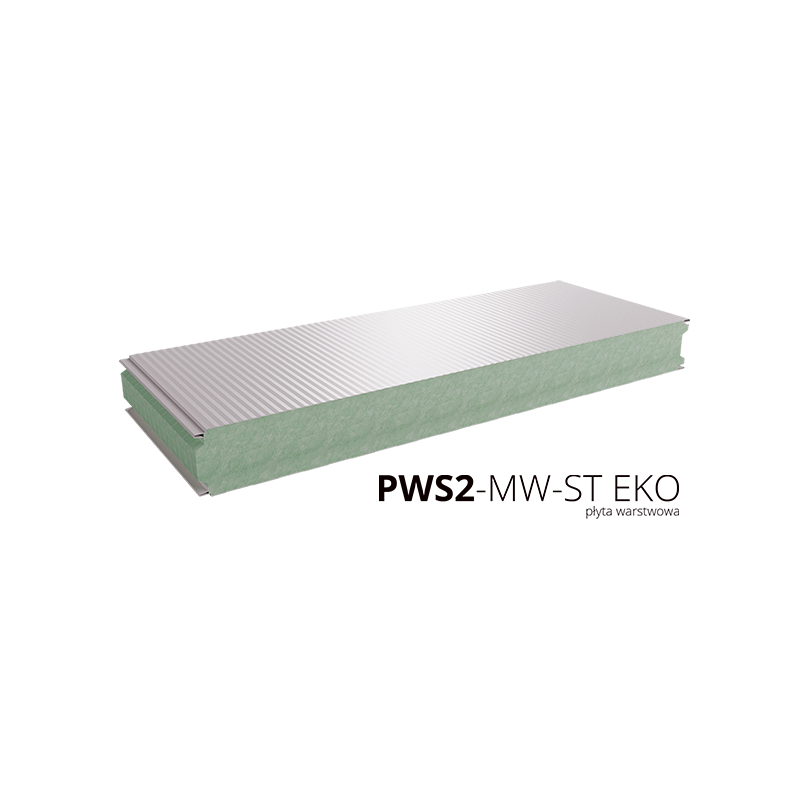

The new generation of sandwich panels with a core of mineral wool (PWS2-MW) offers a wide range of plate variants depending on the detailed requirements and applications. We gradually expand our offer, using the capabilities of our new production line.

Among them is also the EKO variant (PWS2-MW-EKO), in which wool with reduced density is used. This solution significantly reduces the unit mass of the product, which translates into much lighter elements. This is special in the case of investments, which do not require particularly high energy parameters and sound absorption, while the load capacity of the structure is slightly lower.

Next to EKO boards, our offer also includes other new generation plates with a mineral wool insert:

-wall panels with a standard lock (PWS2-MW-ST) << br />

- wall panels with hidden lock (PWS2-MW-PL)- introduction to the offer by the end of 2022

- roof slabs (PWD2-MW-D)- introduction to the offer by the end of 2022

They are all compatible with polyurethane core plates.

The basic physical parameters of PWS2-MW-EKO plates are in the table below. For detailed approvals, certifications and tests, you can find in download files

The table below has a classification divided into color groups for individual colors available in the assortment of Pruszyński Sp. z o.o permissible panel lengths depending on the color of the cladding (minimum length - 2.5 MB) for single -span systems.

16 m wall / 16 m roof

12 m wall / 12 m roof

9 m wall / 9 m roof

ATTENTION- III group – dark colours

Taking in consideration that dark colours from group III has much bigger thermal load and very bright and bright colours from groups I and II, there should be paid special attention during projecting and below conditions are complained:

* For panels with dark colours recommended are single-span schemes; in other case there may occur non-acceptable by Investor strains on external claddings on panels on intermediate supports. Flutings which may occur, complain with norm PN EN 14509 due to acceptable deviation, but may be topic of complaints.

** Maximum length of panels should be in accordance of producer’s guidelines due to type and use of panels – see LENGTH OF PANELS

*** Assembly of panels with dark colours is possible within temperatures 10oC to 35oC. This condition is essential and must be strictly observed.

Assembly of panels in very bright and bright colours is possible within range of temperatures from +5oC to +35oC

More documentation regarding PWS-MW-EKO discs can be found in download

Recommendation for panel selection according to thermal loads

During projecting it’s important to include difference in temperature of external and internal cladding of sandwich panels.Gradients of temperatues due to difference in external temperature T1 and internal temperature T2 are dependent on few factors:

Purpose of building (range of temperatures inside building T2)

localization of building – position due to sun

colour of external steel cladding (T1).

Depending on latitude, height above sea level and distance from sea on europe continent are use 4 different levels of winter temperature (T1 – external cladding):

0, -10oC,

0, -20oC, (for ex. Poland)

0, -30oC, (for ex. scandinavian countries)

Temperatures of external cladding of roof panel which is covered with snow layer is 0oC.

For calculation was assumed external temperature in winter of -20 oC.

Temperature of external cladding T1 has maximum value during summer and is depending of colour and grade of reflection of surface. Values T1, which are minmal for calculation bearing status (SGN) and are proper for calculations of limit status of use (SGU) are:

where RG – grade of reflextion in ratio of magnesium oxide = 100%

Recommended ways of transport for sandwich panels:

Sandwich panels should be storage maximum 2 packages one on another.

In below chart you can see what is maximal quantity of panels in one package.

| thickness of panels | PWS EKO |

|---|---|

| 60 mm | 28pcs. |

| 80 mm | 24pcs. |

| 100 mm | 16pcs. |

| 120 mm | 14pcs. |

| 150 mm | 12pcs. |

All packages should be storage on flat surface with possibility to discharging water.

ATTENTION !!!

In order to extend durability of roofs and elevations it’s recommended to check and conservative it.

ATTENTION!

Pruszyński Sp. z o.o. is not in charge of possible accidents during carrying out all following actions.

The Pruszyński Group has been supporting Polish volleyball for over 15 years and it is undoubtedly […]

Read morePlease be advised that on 01/03/2023 the Fincostal brand will be fully connected to Pruszyński sheet. Considering the interests of our contractors and clients, we took steps for this process to take place maximally smoothly, without any impact on the continuity of the offer and conditions.

Read moreThe beginning of the year is full of unique industry meetings. After Dachforum 2023, which turned out to be a huge success, time for Budma, i.e. the largest event of the construction industry.

Read more