Currently, it is difficult to imagine construction, especially indoor public utilities, industrial and agricultural (storage, cold stores, freezing, farm animals) without housing (cover walls, roofs) in the form of sandwich panels, especially from plates in metal cladding.

Sandwich panels – light layered plates are constructions made up of rationaly and properly connected insulation and construction materials. They consist of external layers (cladding, metal plates) with high mechanical properties that are connected to the central layer (core) made of mineral wool with use of specifically developed glue.

Apart from cover walls and covering, sandwich panels are used as:

Such a wide range of use results from their advantages, which include:

One of the items that are very popular in the commercial offer of Pruszyński Sp. z o. o. are wall and roof layered panels with a core made of rigid polyurethane foam in metal cladding. Responding to the market interest and growing demand, we also introduced the second generation of sandwich panels with a core of mineral wool – PWS2. This latest item in our offer already has a large group of loyal customers that are constantly growing. Hence, we plan to further expand the types of assortments in this category of layer plates. Currently, standard density (ST) and discs with reduced vague and weight are available in the offer.

Wall panels with a maximum modular width of 1150 mm (visible fastening) and 1050 mm (hidden mounting and roof plate) allow you to simple and quick installation to various types of structures using appropriate cruising fasteners. The uniquely designed longitudinal contacts (locks) of the pen and wpust ensure very good tightness, fire resistance and quick assembly.

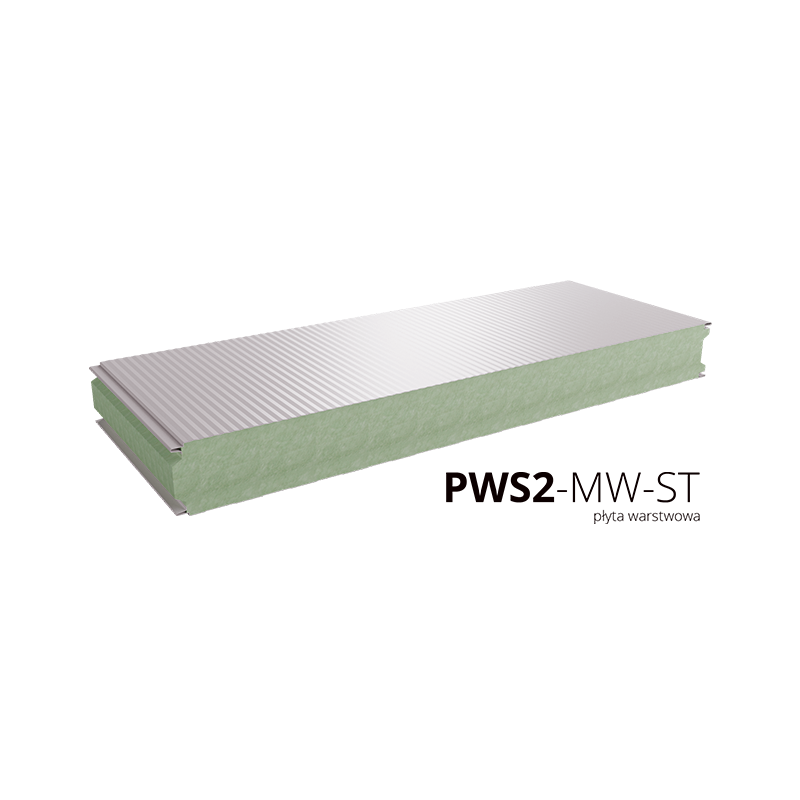

Sandwich panels with mineral wool core, visible joints. Wall layered panels are used especially in indoor, industrial and public construction (shopping centers, warehouse centers, sports halls, etc.). They are especially useful at the points where fire resistance and fireproof features are extremely important.

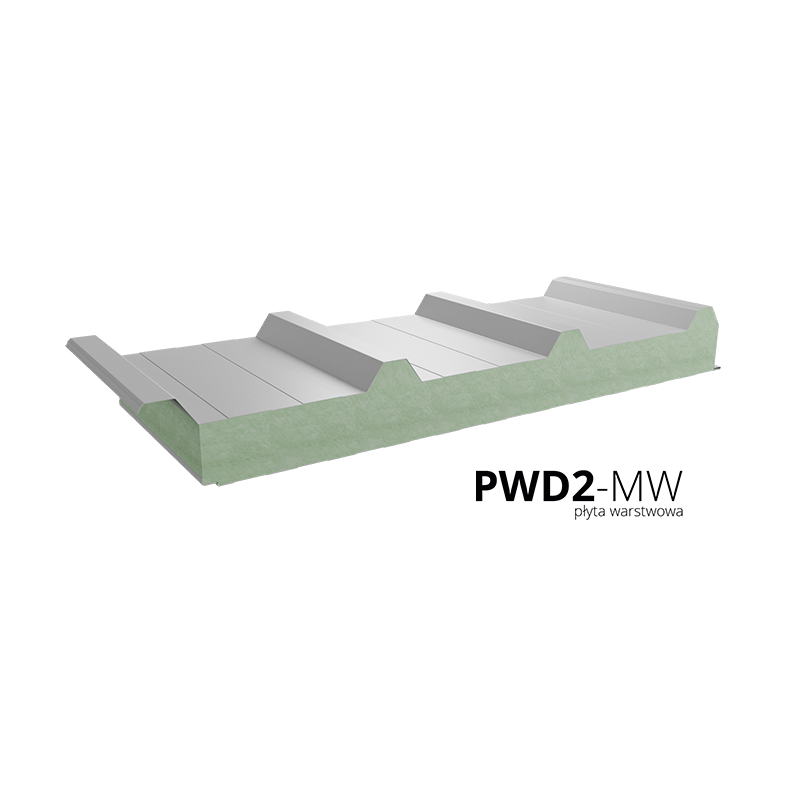

Roof sandwich panels with a mineral wool core (visible fastening) are used in light industrial and commercial development. Thanks to the trapezoidal profiling of the external coating, they offer increased load-bearing capacity of the roof covering and very good drainage properties.

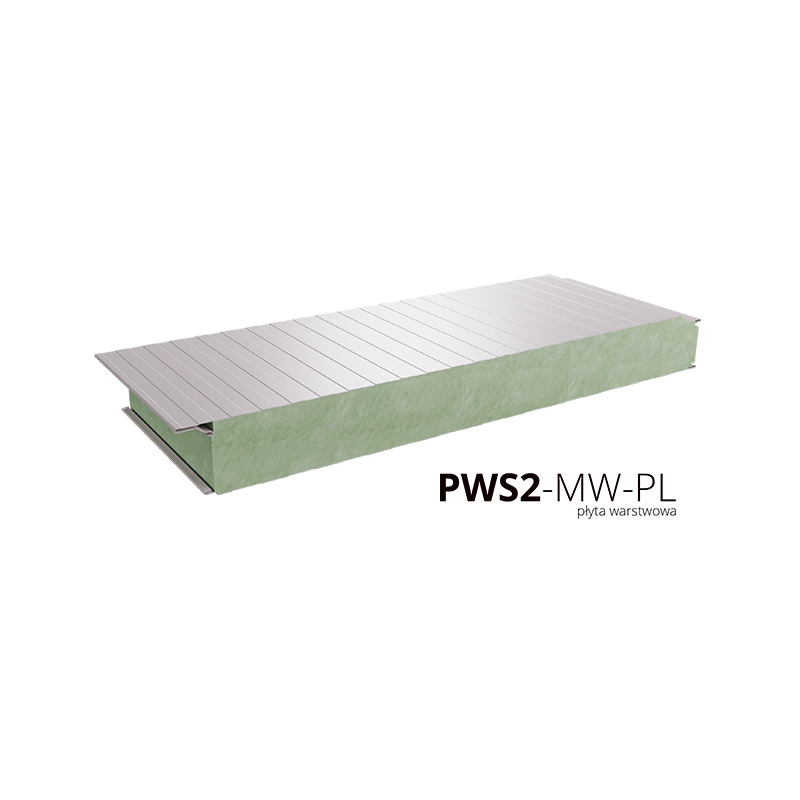

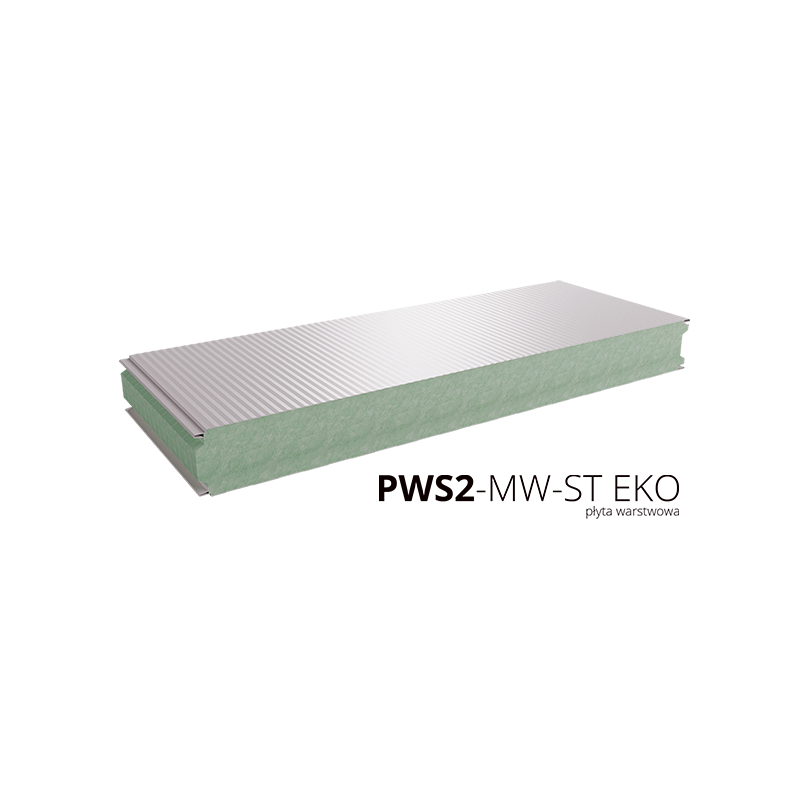

Wall sandwich panels with a mineral wool core PWS2-MW – second generation (hidden fastening) are an excellent product intended for investment construction with a particularly attractive appearance, thanks to hidden joint sections. They are particularly recommended for hall, industrial and public utility construction (sports halls, entertainment halls, storage centers, shopping centers, etc.).

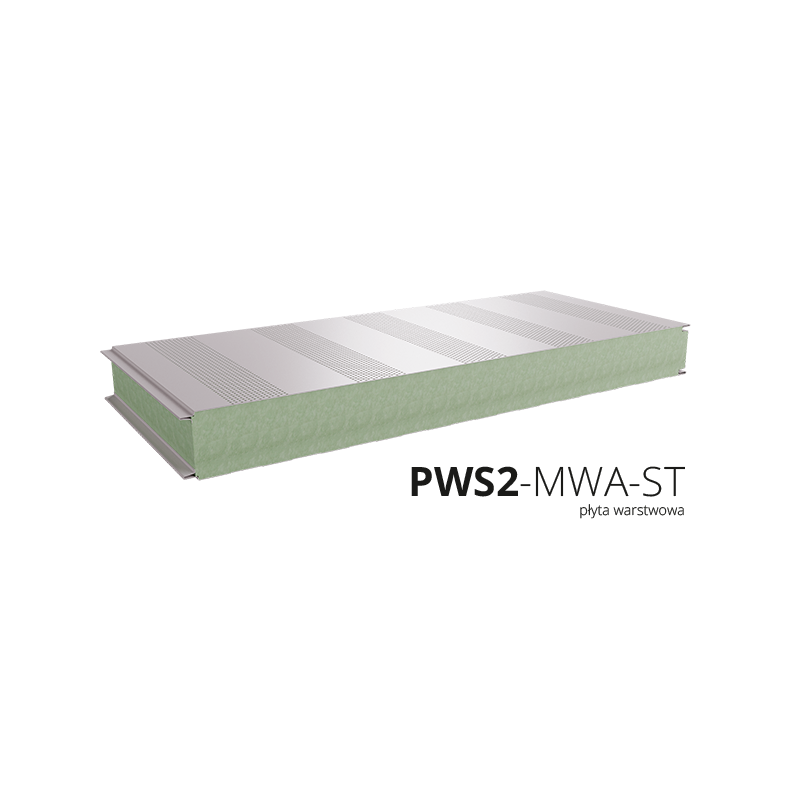

Wall sandwich panels with a mineral wool core and perforated internal cladding are used to reduce noise and nuisance in industrial and investment buildings, and warehouses.

Wall sandwich panels with a mineral wool core of lower density (visible fastening) are used especially in hall, industrial and public utility construction (shopping centers, warehouses, sports halls, etc.). EKO wool is a panel with reduced density, and therefore lower mass, which allows for reducing load-bearing elements.