Modern constructions demands high quality, high performance and fast installation - all to reduce costs and deliver top effects. PIRETECH is the right answer for all those needs - especially for public utility, industrial and agricultural buildings (storage rooms, cold stores, freezers, animal housing). Our product also fits well the role of curtain walls or roofs, thanks to wide range of wariants.

Sandwich panels – light layered plates are constructions made up of rationaly and properly connected insulation and construction materials. They consist of external layers (cladding, metal plates) with high mechanical properties that are connected to the central layer (core) made of mineral wool with use of specifically developed glue.

Apart from cover walls and covering, sandwich panels are used as:

load -bearing walls – in small transportable cold stores, buildings of buildings.

partition walls – in industrial facilities and refrigerators,

Suspended ceilings – wide range of industrial facilities

Most commonly used core for sandwich panels is PIR foam (polyisocyanurate) as well as mineral wool (thanks to excellent fire resistance). Both these materials are more and more common nowadays and supersede older and less efficient solutions like styrofoam. PIR and mineral wool have their own advantages and are used for different purposes. Due to high expectations for thermal insulation – PIR is mostly preferred by both investors as well as architects. Our offer excels a responding to those needs. PIRTECH category consists of variety of variants and types of sandwich panels – which can be applied to any modern investment to achieve best value at the best price.

Huge popularity of sandwich panels as well as wide range of applications result from numerous benefits they offer. They include:

Our commercial offer consists of two main products lines in terms of application – roof sandwich panels and wall sandwich panels. Each of the lines uses the same core – hardened polyisocyanurate foam – put between metal cladding of different external facings. The thickness of the core differs depending on the product variant.

Wall panels with a maximum modular width of 1150 mm (visible fastening – code mark: ST, CH) and 1050 mm (hidden fastening – code mark: PL) and a roof panel (PWD) allow for simple and quick assembly to various types of structures using appropriate pass-through connectors. Additionally uniquely designed joints (tongue-and-groove type) ensure very good tightness as well as thermal insulation – removing problem of thermal bridges. Furthermore that new type of lock (joint) is fully compatible along all our sandwich panels (both PIRTECH and new generation of WOOLTECH sandwich panels) – allowing easily connection between different types of sandwich panels within one building.

Currently our PIRTECH offer consists of 4 basic subcategories of sandwich panels with PIR foam – three for wall application and one for roof application. Each of the subcategory has also its own thickness variants allowing the clients to choose the most suitable option for their needs.

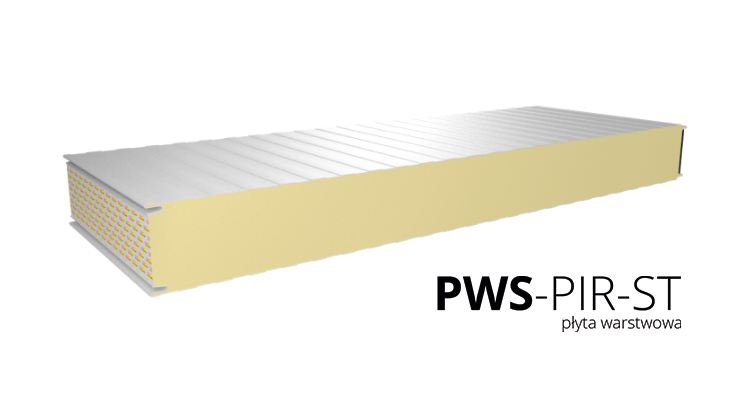

Sandwich panels with PIR foam core, designed for wall (both interior and exterior application). Visible fastening

Maximum modular width: 1150 mm. Allow for simple and quick montage to various types of structures using appropriate pass-through connectors. Uniquely designed longitudinal tongue-and-groove joints (locks) ensure very good tightness, fire resistance and quick assembly.

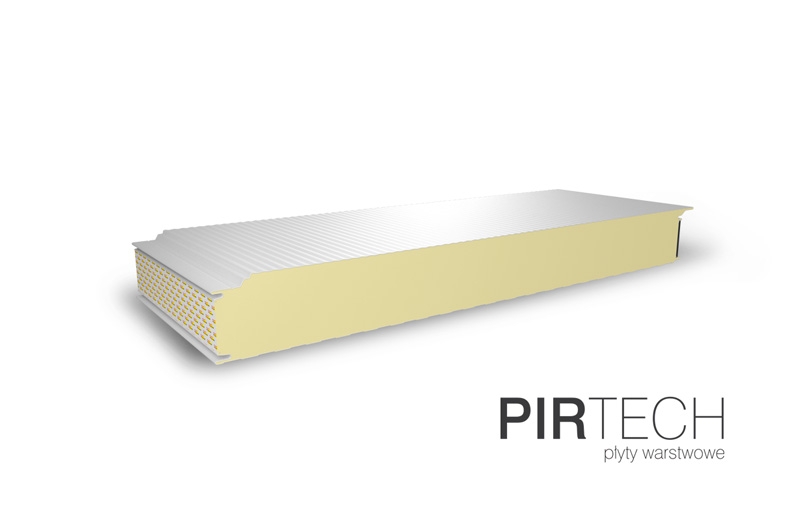

Sandwich panels with PIR foam core, designed for wall (both interior and exterior application). Hidden joint

Maximum modular width – 1050 mm. Shorter width to create special fold and hide the joint underneath. Clever and thought-through design allows to combine all the benefits of standard sandwich panels with unique look and clean design of external elevation.

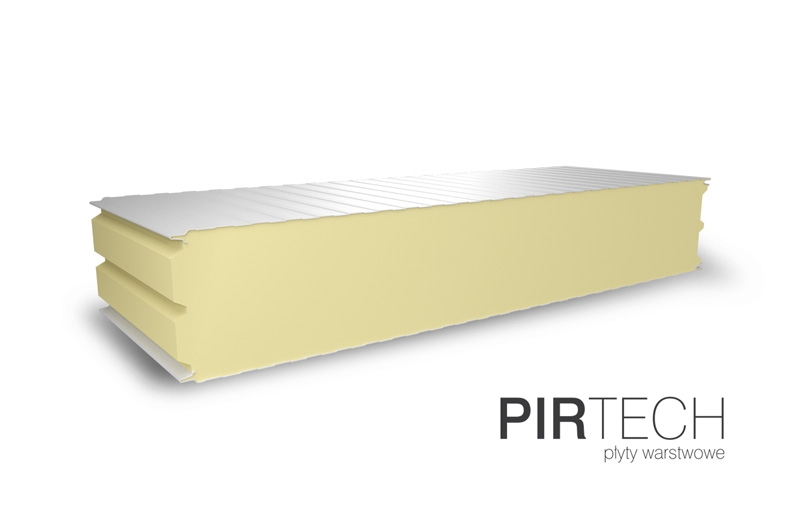

Sandwich panels with PIR foam core, designed for wall application for cold storages to secure maximum thermal insulation. Visible fastening.

Maximum modular width – 1150 mm. Highest possible thickness of the core up to 220 mm of PIR foam provides exceptional thermal insulation parameters. Recommended for external as well as internal usage.

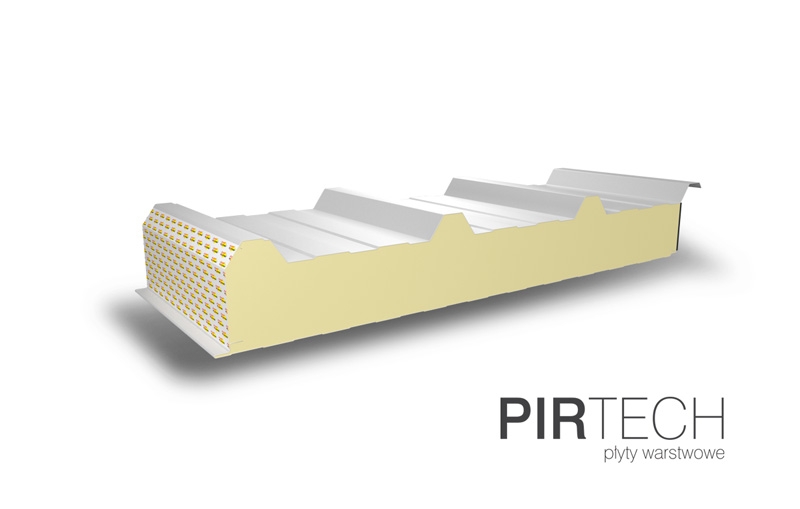

Roof sandwich panels PIRTECH Roof with polyurethane foam core (visible fastening). In addition to curtain walls, sandwich panels are most often used as a roof covering element. They provide relatively simple and automated assembly within the system, which significantly speeds up the construction process of the facility. Due to the completely different stress and loads to which roof sandwich panels are subjected, usually the external sheet metal cladding has a trapezoidal profile with a large pitch, ensuring the appropriate stiffness required on the roof. Note: the panel is only available in widths up to 1050 mm.