Karta produktu

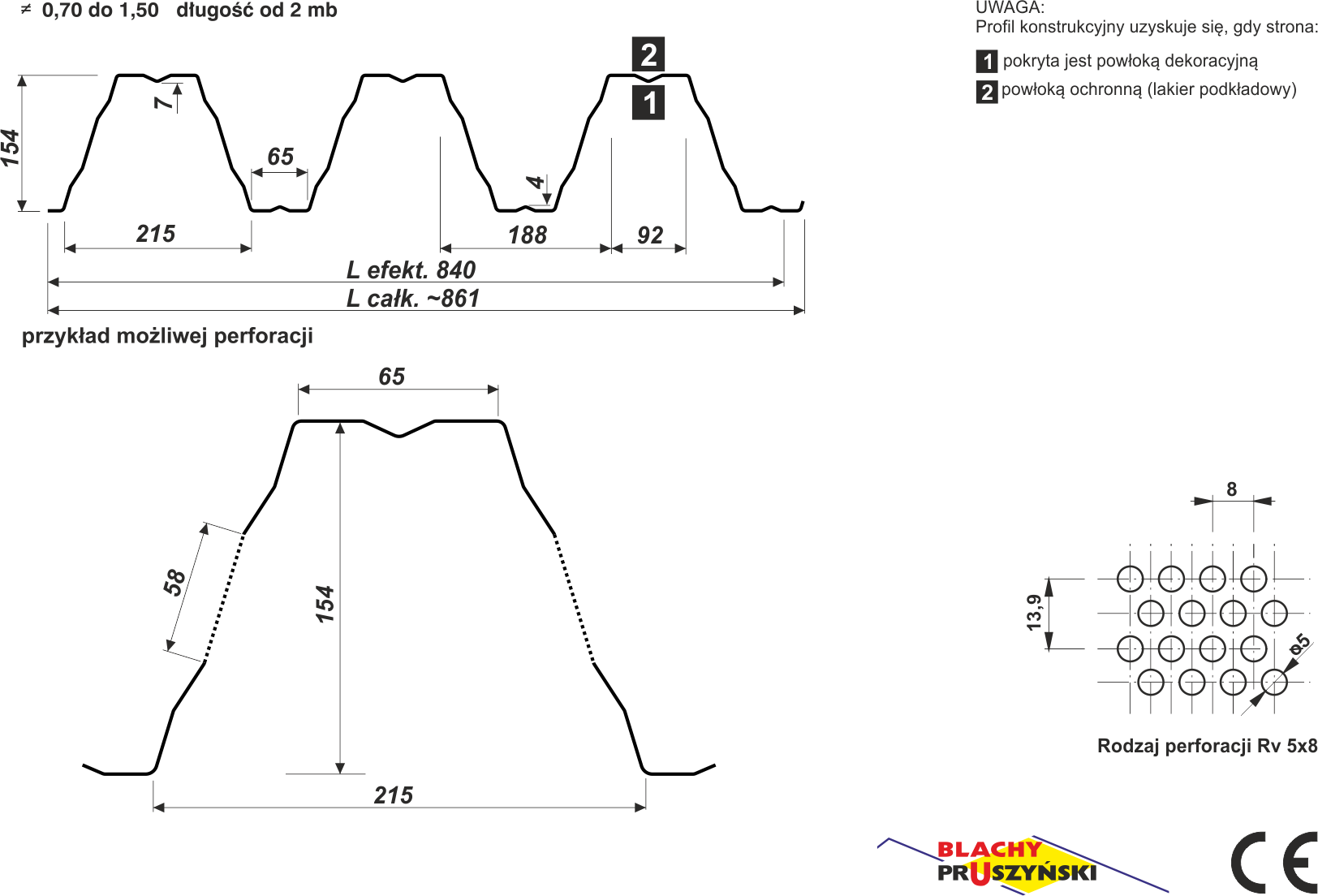

T155 – construction trapezoidal sheet

T155 - constructional trapezoidal sheet

Technical specification

General information

Heigth of profile:

154 mm

Raw material width:

1500 mm

Effective width:

839 mm

Total width:

861 mm

Material:

S 320 GD / S 350 GD

Max. recommended length of sheets:

12/14 mb

Min. length of sheets:

2 mb

Thickness

0,7 - 1,5 mm

Coating

polyester glossy, galvanised

Perforation

available

Usage

roofs, construction elements, ceilings etc.

Recommendations

Transport recommendations

- Transport of trapezoidal sheets should be done with special vehicle which shall have an open loading platform allowing easy loading and unloading, with the length suitable for ordered sheets. The sheets shall not extend beyond the platform otherwise it may cause damage and in consequence loss of the guarantee . The steel sheets must be protected against drifting and soaking.

- Unloading shall be carried out by the proper number of people, that is in the case of long sheets (ca. 6linear metre) the sheets shall be unloaded by 6 people, three on each side.

- Special attention shall be paid not to friction one sheet against the other, bend the side edges or stretch the sheet. Steel sheet deformation during the unloading and moving can result in problems with proper installation (chinks in clamps). It is of course the best to unload in original manufacturer packaging , using mechanical unloading equipment.

- Special carefulness should be maintained during unloading in winter and during storing in heated warehouses.

- Transport of trapezoidal sheets should be done with special vehicle which shall have an open loading platform allowing easy loading and unloading, with the length suitable for ordered sheets. The sheets shall not extend beyond the platform otherwise it may cause damage and in consequence loss of the guarantee . The steel sheets must be protected against drifting and soaking.

- Unloading shall be carried out by the proper number of people, that is in the case of long sheets (ca. 6linear metre) the sheets shall be unloaded by 6 people, three on each side.

- Special attention shall be paid not to friction one sheet against the other, bend the side edges or stretch the sheet. Steel sheet deformation during the unloading and moving can result in problems with proper installation (chinks in clamps). It is of course the best to unload in original manufacturer packaging , using mechanical unloading equipment.

- Special carefulness should be maintained during unloading in winter and during storing in heated warehouses.

- Transport of trapezoidal sheets should be done with special vehicle which shall have an open loading platform allowing easy loading and unloading, with the length suitable for ordered sheets. The sheets shall not extend beyond the platform otherwise it may cause damage and in consequence loss of the guarantee . The steel sheets must be protected against drifting and soaking.

- Unloading shall be carried out by the proper number of people, that is in the case of long sheets (ca. 6linear metre) the sheets shall be unloaded by 6 people, three on each side.

- Special attention shall be paid not to friction one sheet against the other, bend the side edges or stretch the sheet. Steel sheet deformation during the unloading and moving can result in problems with proper installation (chinks in clamps). It is of course the best to unload in original manufacturer packaging , using mechanical unloading equipment.

- Special carefulness should be maintained during unloading in winter and during storing in heated warehouses.

- Transport of trapezoidal sheets should be done with special vehicle which shall have an open loading platform allowing easy loading and unloading, with the length suitable for ordered sheets. The sheets shall not extend beyond the platform otherwise it may cause damage and in consequence loss of the guarantee . The steel sheets must be protected against drifting and soaking.

- Unloading shall be carried out by the proper number of people, that is in the case of long sheets (ca. 6linear metre) the sheets shall be unloaded by 6 people, three on each side.

- Special attention shall be paid not to friction one sheet against the other, bend the side edges or stretch the sheet. Steel sheet deformation during the unloading and moving can result in problems with proper installation (chinks in clamps). It is of course the best to unload in original manufacturer packaging , using mechanical unloading equipment.

- Special carefulness should be maintained during unloading in winter and during storing in heated warehouses.

Storage

- Oiling and passivation of galvanised steel sheets is a form of protection against white corrosion only during the transport.

- Steel sheets stored in packages and coils cannot be stored outside or in premises with high humidity and changing temperatures. Zinc and aluzinc coats, especially if they have not been exposed to atmospheric conditions and thus without securing it protection layer, are vulnerable to water condensate if the access of air is limited (steel sheets stored in stacks). Special attention should be paid to unloading in winter and storing in heated warehouses. As a result of significant difference of temperature, the water arrives between the sheets.

- Sheets which got wet during transport or storing shall be dried, next the sheets shall be separated with washers allowing free air circulation. When dry, the galvanized (aluzinc) sheets shall be inspected and oiled with preservative oil.

- Steel sheets to be stored for a long time shall be inspected and covered with a layer of machine oil ( zinc and aluzinc covered steel sheets) and protected against humidity (all types of steel sheets).

- If the above instructions are not followed, the zinc or aluzinc corrosion – white layers loosely adhered to the sheet , which are not the protection against the steel corrosion – may arrive (in the case of galvanized and aluzinc sheets even within a couple of days).

- The coated steel sheets in manufacturer packaging shall not be stored for more than 3 weeks from the date of manufacturing. After that the packaging shall be opened and the sheets separated with washers allowing for free air circulation. The maximum period of storage shall not exceed 6 months from the date of manufacturing under the pain of loss of guarantee.

- Protective films are applied as additional protection of steel sheets against mechanical damage, stress and impact possible during transport, reloading or forming. Protective films do not exempt the customer from the obligation to protect the sheets properly during their storage or against harmful impact of chemical factors during the processing. It is recommended that the film is removed from each ready to use profile soon before it is to be installed on the wall or the roof.

- Oiling and passivation of galvanised steel sheets is a form of protection against white corrosion only during the transport.

- Steel sheets stored in packages and coils cannot be stored outside or in premises with high humidity and changing temperatures. Zinc and aluzinc coats, especially if they have not been exposed to atmospheric conditions and thus without securing it protection layer, are vulnerable to water condensate if the access of air is limited (steel sheets stored in stacks). Special attention should be paid to unloading in winter and storing in heated warehouses. As a result of significant difference of temperature, the water arrives between the sheets.

- Sheets which got wet during transport or storing shall be dried, next the sheets shall be separated with washers allowing free air circulation. When dry, the galvanized (aluzinc) sheets shall be inspected and oiled with preservative oil.

- Steel sheets to be stored for a long time shall be inspected and covered with a layer of machine oil ( zinc and aluzinc covered steel sheets) and protected against humidity (all types of steel sheets).

- If the above instructions are not followed, the zinc or aluzinc corrosion – white layers loosely adhered to the sheet , which are not the protection against the steel corrosion – may arrive (in the case of galvanized and aluzinc sheets even within a couple of days).

- The coated steel sheets in manufacturer packaging shall not be stored for more than 3 weeks from the date of manufacturing. After that the packaging shall be opened and the sheets separated with washers allowing for free air circulation. The maximum period of storage shall not exceed 6 months from the date of manufacturing under the pain of loss of guarantee.

- Protective films are applied as additional protection of steel sheets against mechanical damage, stress and impact possible during transport, reloading or forming. Protective films do not exempt the customer from the obligation to protect the sheets properly during their storage or against harmful impact of chemical factors during the processing. It is recommended that the film is removed from each ready to use profile soon before it is to be installed on the wall or the roof.

Cutting and assembly

- To cut sheets should be used special roofer’s cutter. After assembly all filing and turnigs should be removed form surface of roof. In case of any damages, it should be repaired immidiately with proper touch up paint.

- In case of using grinding machine, any complaints wont be accepted.

Other information can be found in assembly instruction to specific product.

- To cut sheets should be used special roofer’s cutter. After assembly all filing and turnigs should be removed form surface of roof. In case of any damages, it should be repaired immidiately with proper touch up paint.

- In case of using grinding machine, any complaints wont be accepted.

Other information can be found in assembly instruction to specific product.

Maintenance

- In order to extend durability of roofs and elevations it’s recommended to check and conservative it.

- Inspection – One time a year (it’s best in spring) there should be inspection of roof/elevation in order to early detection of possible damage.

- Cleaning of steel sheet – Roof and elevation made of steel sheets require cleaning at least once a year. Stratifying dirt on steel sheet may cause uneven discoloration of lacquer (because of uneven impact of UV beams), and lower protection to corrosion(dust traps humidity on steel sheets which causes damage). Dirty and stained spots can be cleaned by soft brush and water (temp. max. 60c). If it is necessary it is permitted to use some light detergent (ph 6/7, max 10% solution). There also can be used pressed water(max. 100bar) to cleaning, however the beam of water cannot be applicated too near of surface of sheets(min. 30 cm), also it shouldn’t be perpendicularly to surface. Near the connections water beam should be directed to bottom, to avoid water of entering cracks near connections. With old surfaces of steel sheets we should deal with high cautiously. Cleaning should be conducted from top to bottom, and cleaned spots should be rinsed out immediately.

- It is not permitted to use scouring powders, nitro solvent, chlorine liquor, aromatised substances, substances with Amon chloride or sodium.

- Damages – Possible damages during guarantee should be consulted with Contractor of roof/elevation and can be repaired only with his written permission.Repair of damages on small surfaces is done with quick-drying varnish. However painting big surfaces should be done with special industrial paints to renovating coverings. Painting should be limited only to special damaged spots (scratches to steel, centres of corrosion etc.)Preparation of surface to painting should be done with generally accepted rules. It is necessary to precisely remove all signs of corrosion – best with special brush or close-grained sandpaper. Then that surface should be undusted, degreased and cleaned. To degrease extraction naptha or water with addition of surfactant(best with 1-2%solution of ammoniac) can be used. Repaired spots may be different in colour compared to original steel sheets because of natural impact of atmospheric phenomenon (ageing of varnish due to impact of UV radiation)

- ATTENTION!– During inspecting, cleaning, conservation and repair all work safety regulations should be obeyed.Pruszyński Sp. z o.o. is not in charge of possible accidents during carrying out all following actions.

- In order to extend durability of roofs and elevations it’s recommended to check and conservative it.

- Inspection – One time a year (it’s best in spring) there should be inspection of roof/elevation in order to early detection of possible damage.

- Cleaning of steel sheet – Roof and elevation made of steel sheets require cleaning at least once a year. Stratifying dirt on steel sheet may cause uneven discoloration of lacquer (because of uneven impact of UV beams), and lower protection to corrosion(dust traps humidity on steel sheets which causes damage). Dirty and stained spots can be cleaned by soft brush and water (temp. max. 60c). If it is necessary it is permitted to use some light detergent (ph 6/7, max 10% solution). There also can be used pressed water(max. 100bar) to cleaning, however the beam of water cannot be applicated too near of surface of sheets(min. 30 cm), also it shouldn’t be perpendicularly to surface. Near the connections water beam should be directed to bottom, to avoid water of entering cracks near connections. With old surfaces of steel sheets we should deal with high cautiously. Cleaning should be conducted from top to bottom, and cleaned spots should be rinsed out immediately.

- It is not permitted to use scouring powders, nitro solvent, chlorine liquor, aromatised substances, substances with Amon chloride or sodium.

- Damages – Possible damages during guarantee should be consulted with Contractor of roof/elevation and can be repaired only with his written permission.Repair of damages on small surfaces is done with quick-drying varnish. However painting big surfaces should be done with special industrial paints to renovating coverings. Painting should be limited only to special damaged spots (scratches to steel, centres of corrosion etc.)Preparation of surface to painting should be done with generally accepted rules. It is necessary to precisely remove all signs of corrosion – best with special brush or close-grained sandpaper. Then that surface should be undusted, degreased and cleaned. To degrease extraction naptha or water with addition of surfactant(best with 1-2%solution of ammoniac) can be used. Repaired spots may be different in colour compared to original steel sheets because of natural impact of atmospheric phenomenon (ageing of varnish due to impact of UV radiation)

- ATTENTION!– During inspecting, cleaning, conservation and repair all work safety regulations should be obeyed.Pruszyński Sp. z o.o. is not in charge of possible accidents during carrying out all following actions.

Polyester glossy

Technical specification of the coating

thickness of coating

25 µm

corrosion resistance

High ★★★☆

UV resistance

Good ★★☆☆

possibility of bending

Good ★★☆☆

Available colours

Dowolna grubość

0,50 mm

0,70 mm

1,00 mm

Metallic coatings

Technical specification of the coating

Available colours

Powłoki metaliczne

AZ – aluzynk

OC – galvanist

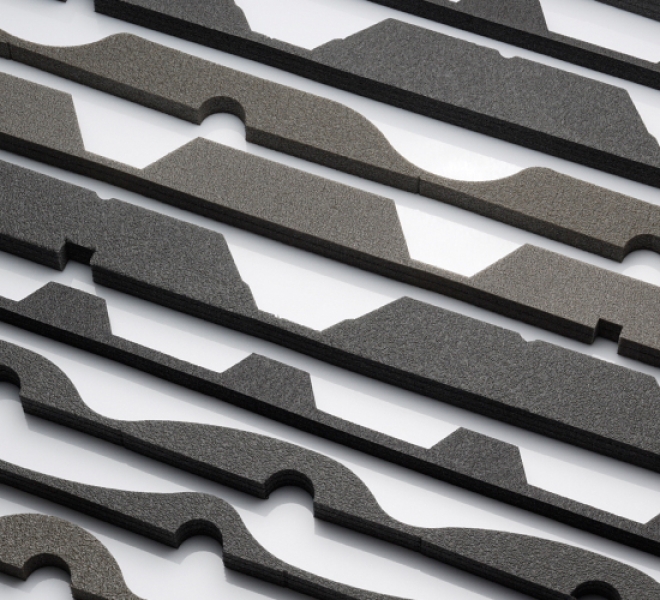

Product description

Construction trapezoids

High embossing profiles are structural elements and due to their high strength they are used on roofs with large spans.

High strength parameters mean that they are used in the construction of large industrial and commercial facilities. These sheets can be used in load -bearing constructions with large span and for ceilings.