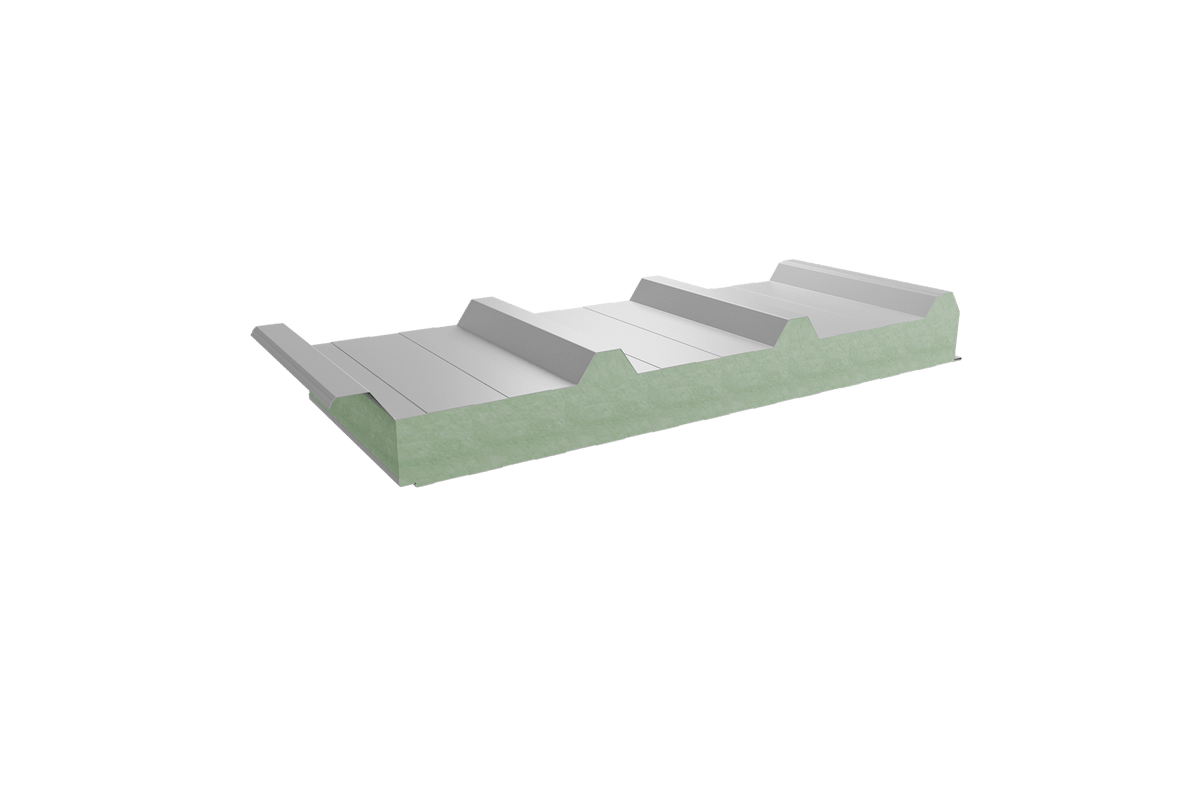

PWD2-MW-100 - Roof sandwich panel - mineral wool - visible joint

Sandwich panel - mineral wool core, density 115 kg/m3 thickness 100 mm

Technical specification

General information

The roof sandwich panel with a mineral wool core (WOOLTECH Dach), manufactured by Blacha Pruszyński, is manufactured on a modern production line, maintaining the highest quality standards. It is a roof panel with a wool core of the second generation, ensuring very high thermal insulation parameters with excellent fire properties at the same time. The mineral wool core is placed between two galvanized, coated sheet metal claddings. Our offer includes various types of coatings and colors to choose from, as well as core thicknesses from 100 to 240 mm. The roof profile of the external cladding (trapezoidal, 40 mm high) ensures very good water drainage parameters.

Depending on the method of installation of the panels, the recommended minimum roof slopes are:

* for roofs made of continuous panels (without cross-connection along the length)

** for roofs made of panels connected crosswise along the length

*** flat internal profiling (P), available only for sheet thicknesses above 0.6 mm

flat - P ***

Physical properties

RA1 = 27 dB

RA2 = 26 dB

Panels length

The table below contains a classification divided into color groups for individual colors available in the Pruszyński Sp. z o. o. Permissible board lengths depending on the color of the cladding (minimum length - 2.5 m) for single-span systems.

Group I (very bright colors)

16 m wall / 16 m roof

Group II (bright colors)

12 m wall / 16 m roof

SILVER

Group III (dark colors)

9 m wall / 13,5 m roof

SILVER METALLIC

* Colors marked with an asterisk are not available in the standard offer. Please send individual color inquiries directly via the contact form.

Read more below.

Recommendations for the selection of panels in the context of thermal loadsNOTE – group III – dark colors

Taking into account that dark colors from Group III are subject to much greater thermal loads than very light and light colors from groups I and II, special attention should be paid when designing to ensure that the following conditions are met:

the mounting method and static system must comply with the tables of permissible loads and spans (criteria met – ultimate limit state, serviceability limit state)*

limit the maximum length of boards according to the manufacturer’s recommendations**

take into account the installation temperature***

* Single-span systems are recommended for dark-colored panels; otherwise, deformations of the outer slab cladding may occur on the intermediate supports and are unacceptable to the Investor. The corrugations in question meet the requirements of the PN EN 14509 standard in terms of permissible deviations, however, they may cause complaints.

** Maximum board lengths should be in accordance with the manufacturer’s guidelines depending on the type of board and their application (roof/wall) – see BOARD LENGTHS. At the customer’s request and after signing the declaration, it is possible to deliver roof panels in Group III colors, 16 m long.

*** Installation of dark colored boards is possible at temperatures from 10oC to 35oC. This condition must be strictly observed. Installation at temperatures lower than 10oC (or higher than 35oC) may lead to deformation and permanent damage of the board during the use of the building (in extreme cases also during installation). In this case, deformations and damage to the board are caused by the high elongation of the linings (e.g. at summer temperatures) in relation to the initial length (length of the lining during installation).

Installation of boards in light and very light colors is possible in the temperature range from +5oC to +35oC.

Failure to comply with the above guidelines may result in surface deformations on the boards and local loss of stability, for which the manufacturer is not responsible. In the case of colors not included in the table, please contact Pruszyński’s technical advisor. The color of the board may be changed only with the designer’s consent.

NOTE – group III – dark colors

Taking into account that dark colors from Group III are subject to much greater thermal loads than very light and light colors from groups I and II, special attention should be paid when designing to ensure that the following conditions are met:

the mounting method and static system must comply with the tables of permissible loads and spans (criteria met – ultimate limit state, serviceability limit state)*

limit the maximum length of boards according to the manufacturer’s recommendations**

take into account the installation temperature***

* Single-span systems are recommended for dark-colored panels; otherwise, deformations of the outer slab cladding may occur on the intermediate supports and are unacceptable to the Investor. The corrugations in question meet the requirements of the PN EN 14509 standard in terms of permissible deviations, however, they may cause complaints.

** Maximum board lengths should be in accordance with the manufacturer’s guidelines depending on the type of board and their application (roof/wall) – see BOARD LENGTHS. At the customer’s request and after signing the declaration, it is possible to deliver roof panels in Group III colors, 16 m long.

*** Installation of dark colored boards is possible at temperatures from 10oC to 35oC. This condition must be strictly observed. Installation at temperatures lower than 10oC (or higher than 35oC) may lead to deformation and permanent damage of the board during the use of the building (in extreme cases also during installation). In this case, deformations and damage to the board are caused by the high elongation of the linings (e.g. at summer temperatures) in relation to the initial length (length of the lining during installation).

Installation of boards in light and very light colors is possible in the temperature range from +5oC to +35oC.

Failure to comply with the above guidelines may result in surface deformations on the boards and local loss of stability, for which the manufacturer is not responsible. In the case of colors not included in the table, please contact Pruszyński’s technical advisor. The color of the board may be changed only with the designer’s consent.

Transport recommendations

Recommended means of transport for sandwich panels:

- A truck (tractor + semi-trailer with a length not shorter than the length of the loaded panels) with an open semi-trailer or one enabling side loading on both sides along its entire length

- The weight of the load cannot exceed the permissible load capacity of the set,

- Transport belts should be placed on the load at a distance of max. every 3 m, but not less than 2 belts per package – the tension of the belts must not cause deformation of the boards.

Storing recommendations

Sandwich panels should be stored in packages (posts), a maximum of two packages can be stored on top of each other.

The table below shows the max. number of boards that can be arranged in one package.

| panel thickness | PWD2-MW |

| 100 mm | 10 items |

| 120 mm | 8 items |

| 140 mm | 6 items |

| 150 mm | 6 items |

| 160 mm | 6 items |

| 180 mm | 6 items |

| 200 mm | 4 items |

| 220 mm | 4 items |

| 230 mm | 4 items |

| 240 mm | 4 items |

| 250 mm | 4 items |

- It is recommended to store the boards on a flat surface (square, hall) on joists or polystyrene sleepers, which must be spaced a maximum of 2.5 m apart (for boards with a total length of up to 2.5 m, at least 3 sleepers should be used).

- It is allowed to store a maximum of two board packages up to 6 meters in size, one on top of the other; in the case of board packages above 1 meter, they should be stored individually. All board packages must be stored on a level surface with the ability to drain water.

- When storing boards at the construction site, they should be protected against mechanical damage, exposure to UV rays, aggressive environments (acids, fertilizers, salts and other corrosive factors), precipitation, strong wind and others.

- It is recommended to store packages under a roof in ventilated rooms

The boards should be stored on an even surface (square, hall) on joists, polystyrene or wooden sleepers, which must be spaced a maximum of every 2.5 m (for boards with a total length of up to 2.5 m, at least 3 sleepers should be used ). - Protective foils are used to additionally protect the board surface against mechanical damage, stresses and impacts that may occur during transport or reloading. Foils never relieve you of the obligation to properly protect the boards during storage.

- It is recommended to remove the protective foil before mounting the elements on the facade or roof of the building. Removing the foil should be done at positive air temperatures, because at negative temperatures the adhesive delaminates and some of its components may remain on the sheet.

- Improper storage of sheets may make it difficult to remove the protective foil and leave traces of glue on the surface of the sheets. In such cases, complaints about adhesive residues left by the protective foil will not be accepted by the Manufacturer.

- In the case of boards with hidden fastening, make sure that the foil is removed from the inside of the longer lock before installation.ATTENTION !!!In the case of wall panels with visible fastening, the upper side of the panels in the package is the façade side, which should be paid special attention!

Conservation and cleaning

In order to extend the durability of roofs and facades made of coated sheet metal, they should be regularly inspected and maintained.

- Inspection – Once a year (preferably in spring), the roof/facade should be inspected to detect any damage early.

- Cleaning sheet metal – Roofs/facades made of coated sheet metal require cleaning at least once a year. Dirt settling on the sheet metal may cause uneven discoloration of the color (the result of uneven exposure to UV rays), as well as reduce corrosion resistance (dirt retains moisture on the sheet metal, gradually damaging it). Dirty and stained places can be cleaned with a soft brush and water (max. temperature 60°C). If necessary, a mild detergent can be added to the water (pH 6÷7, max. 10% solution). Pressurized water (max. 100 bar) can also be used for cleaning, however, the water jet cannot be used too close to the surface of the board (min. 30 cm) and cannot be directed perpendicular to the surface. At the connectors, the water stream should be directed downwards to avoid pressurized water from entering the gaps around the connectors. Old board coatings should be handled with extreme caution. Washing should be carried out from top to bottom and the cleaned area should always be thoroughly rinsed immediately with clean water.

- Do not use scouring powders, nitro solvents, chlorine solutions, aromatic agents, as well as agents containing salmiak (ammonium chloride) or sodium salts.

- Damage – Possible damage during the warranty period must be consulted with the roof/facade Contractor and may only be performed with his written consent. Damage to small surfaces can be repaired using air-drying repair varnishes, while painting large surfaces is generally only possible using special industrial paints adapted to the renovation of coverings. The surface to be painted should be limited only to places requiring it (scratches to the metal layer, corrosion spots, etc.). Preparation of the surface for painting should be carried out according to generally accepted rules. Always carefully remove all traces of corrosion – preferably using special brushes or fine-grained sandpaper. Then the repaired surface must be thoroughly dusted, degreased and cleaned. To degrease the surface, you can use extraction gasoline or water with surfactants (preferably with the addition of 1-2% ammonia solution). The repaired zones may show differences in color compared to the original colors of the sheet metal due to the natural impact of atmospheric phenomena (aging of the varnish under the influence of UV radiation).

- ATTENTION – During inspection, cleaning, maintenance and repairs, health and safety rules must be strictly observed.

The company Pruszyński Sp. z o. o. is not responsible for any accidents resulting from the above activities.

Technical specification of the coating

Available colours

SILVER

SILVER METALLIC

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Product description

Roof sandwich panels are used especially in hall, industrial and public buildings (shopping centers, warehouse centers, sports halls, etc.). Roof sandwich panels are basically used only as roof coverings, where they fulfill their function perfectly.

The rich color palette and various shapes of the panels’ profiles enable the creation of a number of interesting objects. Roof sandwich panels with a wool core offer exceptional fire resistance parameters and very high acoustic insulation parameters