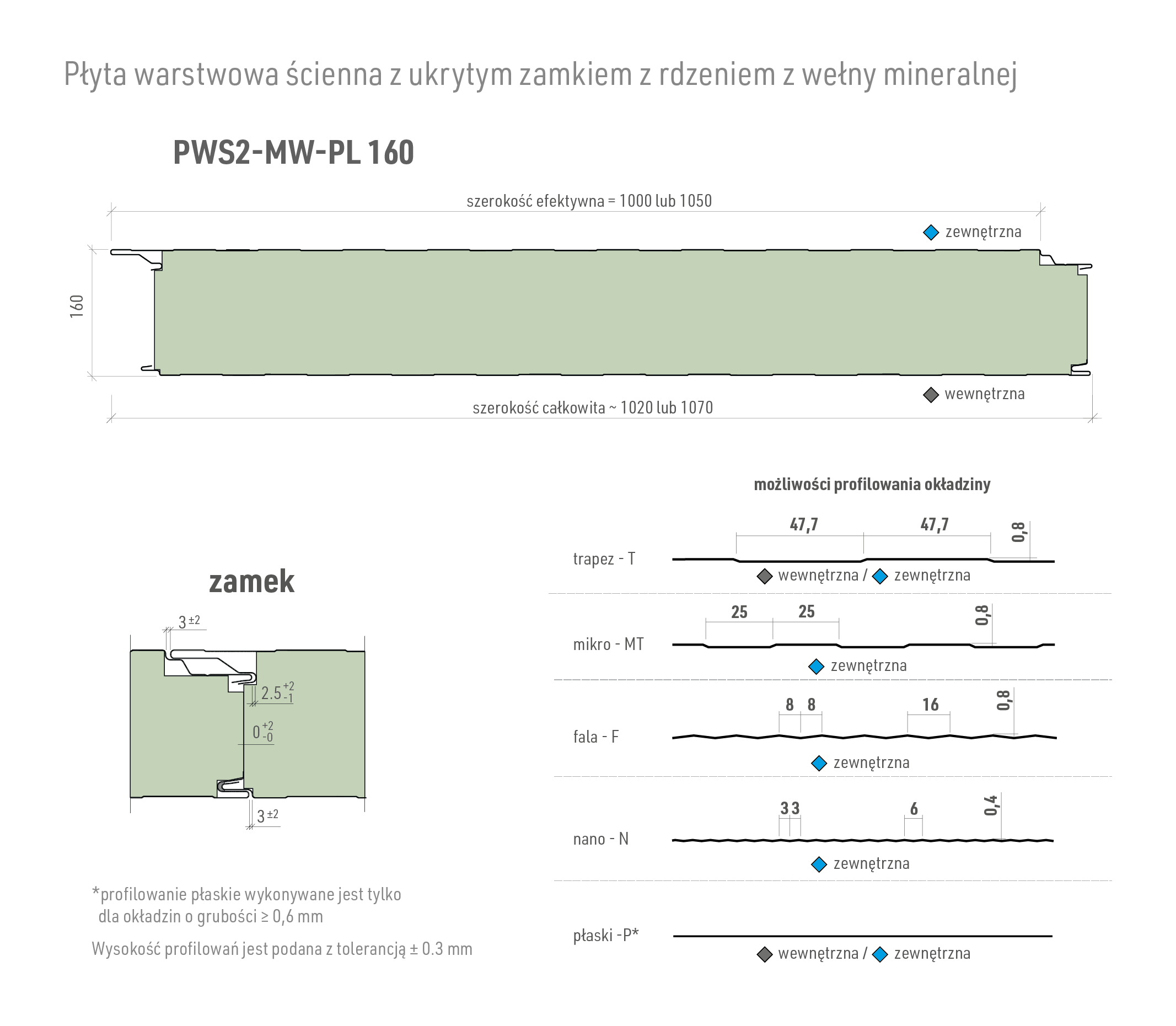

PWS2 -MW -PL -160 - wall sandwich panel - mineral wool - hidden fastening

Technical specification

General information

* Flat outer profiling (P), available only from the thickness of sheet metal above 0.6 mm

micro trapezoidal - M

wave - F

nano-wave - N

flat - P*

flat - P*

Physical properties

The basic technical and physical parameters of the product can be found in the tables and combinations below. In order to familiarize yourself with the values of our products, please contact us directly at the email address: inwestycje@pruszynski.eu

In terms of approvals and certificates – full documentation is in the download section

| Thermal trasmittance value – Uc (W/m2K) | |

| Fire resistance | EI90 (o↔i) (vert 7,5m)EI120 (o↔i) (vert 6,0m) |

| Flame propagation by wall/ reaction to fire | |

| Airborne sound insulation (dB) | Rw30 |

| Sound absorption (αw) | NPD |

Recommendations for the selection of plates in the context of thermal loads

When designing, the temperature differences between layered panel cladding should be taken into account. Temperature gradients resulting from the temperature difference between the T1 outer temperature and the T2 internal temperature depend on several factors:

the purpose of the object (temperature range inside the object – T2)

facility location – location relative to the sun

The color of the outer cladding (T1).

Depending on the latitude, height above sea level and distance from the sea on the European continent, four different levels of winter temperature (T1 – outer cladding) are used:

0, -10°C,

0, -20°C, (e.g. Poland)

0, -30°C, (e.g. Scandinavian countries)

The temperature of the external cladding for roof plates covered with a snow cover layer is 0°C.

The external temperature during the winter -20 °C was adopted for calculations.

The temperature of the T1 outer cladding has a maximum value in the summer and it depends on the color and degree of surface reflection. T1 values, which are minimal for calculations of the load capacity (SGN) and suitable for calculations of the limit state of use (SGU), are as follows:

- very bright colors rg = 75-90 t1 = +55°C

- bright colors rg = 40-74 t1 = +65°C

- dark colors rg = 8-39 t1 = +80°c

where RG- is the degree of reflection of the radius in relation to magnesium oxide = 100%

The table below has a classification divided into color groups for individual colors available in the assortment of Pruszyński Sp. z o.o.

Length of panel

The table below has a classification divided into color groups for individual colors available in the assortment of Pruszyński Sp. z o.o permissible panel lengths depending on the color of the cladding (minimum length - 2.5 MB) for single -span systems.

group I (very bright colors)

16 m wall / 16 m roof

group II (bright colors)

12 m wall / 12 m roof

SILVER

group III (dark colors)

9 m wall / 9 m roof

SILVER METALLIC

* The colors marked with the star are not available in the standard offer. Please direct individual queries in terms of colors using the contact form.

Read more below.

Recommendations for the selection of plates in the context of thermal loadsATTENTION- III group – dark colours

Taking in consideration that dark colours from group III has much bigger thermal load and very bright and bright colours from groups I and II, there should be paid special attention during projecting and below conditions are complained:

- Way of assembly and static scheme must be in accordance with chart of maximum load and span length(complain conditions – limit status of bearing capacity, limit status of use)*

- Max length of panels should be limited due to producer’s guidelines**

- Temperature during assembly***

* For panels with dark colours recommended are single-span schemes; in other case there may occur non-acceptable by Investor strains on external claddings on panels on intermediate supports. Flutings which may occur, complain with norm PN EN 14509 due to acceptable deviation, but may be topic of complaints.

** Maximum length of panels should be in accordance of producer’s guidelines due to type and use of panels – see LENGTH OF PANELS

*** Assembly of panels with dark colours is possible within temperatures 10oC to 35oC. This condition is essential and must be strictly observed.

Assembly of panels in very bright and bright colours is possible within range of temperatures from +5oC to +35oC

ATTENTION- III group – dark colours

Taking in consideration that dark colours from group III has much bigger thermal load and very bright and bright colours from groups I and II, there should be paid special attention during projecting and below conditions are complained:

- Way of assembly and static scheme must be in accordance with chart of maximum load and span length(complain conditions – limit status of bearing capacity, limit status of use)*

- Max length of panels should be limited due to producer’s guidelines**

- Temperature during assembly***

* For panels with dark colours recommended are single-span schemes; in other case there may occur non-acceptable by Investor strains on external claddings on panels on intermediate supports. Flutings which may occur, complain with norm PN EN 14509 due to acceptable deviation, but may be topic of complaints.

** Maximum length of panels should be in accordance of producer’s guidelines due to type and use of panels – see LENGTH OF PANELS

*** Assembly of panels with dark colours is possible within temperatures 10oC to 35oC. This condition is essential and must be strictly observed.

Assembly of panels in very bright and bright colours is possible within range of temperatures from +5oC to +35oC

Recommendations

Transport recommendationsRecommended means of transport for sandwich panels:

- truck (tractor tractor + semi -trailer with a length not shorter than the length of the loaded plates) with an open semi -trailer or enabling side loading on its entire length

- The weight of the load may not exceed the permissible load capacity of the set,

- Transport belts should be placed on a load at a distance of max. Every 3 m, but not less than 2 belts per package – belt tension cannot cause deformation of the plates.

Recommended means of transport for sandwich panels:

- truck (tractor tractor + semi -trailer with a length not shorter than the length of the loaded plates) with an open semi -trailer or enabling side loading on its entire length

- The weight of the load may not exceed the permissible load capacity of the set,

- Transport belts should be placed on a load at a distance of max. Every 3 m, but not less than 2 belts per package – belt tension cannot cause deformation of the plates.

StorageLayered boards should be stored in packages (posts), it is allowed to store a maximum of two packages one on top of

The following table is given max. The number of discs that can be arranged in one package.

Panel thickness

PWS

60 mm

18 pcs

80 mm

14 pcs

100 mm

11 pcs

120 mm

9 pcs

140 mm

8 pcs

160 mm

7 pcs

180 mm

6 pcs

200 mm

5 pcs

220 mm

5 pcs

240 mm

4 pcs

260 mm

4 pcs

- It is recommended to store plates on an even surface (square, hall) on joists or polystyrene sleepers, which must be set up a maximum of 2.5 m (with plates with a total length of up to 2.5 m, use min. 3 foundations).

- It is allowed to store a maximum of two panel packages up to 6MB one on the other, in the case of board packages above MB should be stored individually. All panel packages must be stored on an equal surface with the possibility of draining water.

- When storing panels on the construction site, they should be protected against mechanical damage, exposure to UV rays, an aggressive environment (acids, fertilizers, salts and other corrosion factors), atmospheric precipitation, strong wind and others.

- It is recommended to store parcels under roofing in ventilated rooms

- Storage of plates should be carried out on an equal surface (square, hall) on joists, polystyrene or wooden foundations, which must be set up a maximum of 2.5 m (with plates with a total length of up to 2.5 m should be used at least 3 foundations ).

- Protective films are used to additional protecting the surfaces of the plates against mechanical damage, stresses and impacts that can occur during transport or transhipment. Foils never release from the obligation to properly protect the plates during storage.

- It is recommended to remove protective foil against attachment of elements on the facade or roof of the building. The foil should be removed at positive air temperatures, because at negative temperatures the adhesive is stratified and some of its components may remain on the baking tray.

- Incorrect way of storing sheets can cause difficulties in removing protective film and leave glue traces on the surface of the plates. In such cases, complaints on the remains of glue after protective film will not be included by the manufacturer.

- In the case of hidden fastening panels, pay attention that the foil is removed from the inside of the longer lock before assembly.

ATTENTION !!!

In the case of wall panels with visible fastening, the upper side of the panels in the package is a facade side, which should be paid special attention!

Layered boards should be stored in packages (posts), it is allowed to store a maximum of two packages one on top of

The following table is given max. The number of discs that can be arranged in one package.

| Panel thickness | PWS |

| 60 mm | 18 pcs |

| 80 mm | 14 pcs |

| 100 mm | 11 pcs |

| 120 mm | 9 pcs |

| 140 mm | 8 pcs |

| 160 mm | 7 pcs |

| 180 mm | 6 pcs |

| 200 mm | 5 pcs |

| 220 mm | 5 pcs |

| 240 mm | 4 pcs |

| 260 mm | 4 pcs |

- It is recommended to store plates on an even surface (square, hall) on joists or polystyrene sleepers, which must be set up a maximum of 2.5 m (with plates with a total length of up to 2.5 m, use min. 3 foundations).

- It is allowed to store a maximum of two panel packages up to 6MB one on the other, in the case of board packages above MB should be stored individually. All panel packages must be stored on an equal surface with the possibility of draining water.

- When storing panels on the construction site, they should be protected against mechanical damage, exposure to UV rays, an aggressive environment (acids, fertilizers, salts and other corrosion factors), atmospheric precipitation, strong wind and others.

- It is recommended to store parcels under roofing in ventilated rooms

- Storage of plates should be carried out on an equal surface (square, hall) on joists, polystyrene or wooden foundations, which must be set up a maximum of 2.5 m (with plates with a total length of up to 2.5 m should be used at least 3 foundations ).

- Protective films are used to additional protecting the surfaces of the plates against mechanical damage, stresses and impacts that can occur during transport or transhipment. Foils never release from the obligation to properly protect the plates during storage.

- It is recommended to remove protective foil against attachment of elements on the facade or roof of the building. The foil should be removed at positive air temperatures, because at negative temperatures the adhesive is stratified and some of its components may remain on the baking tray.

- Incorrect way of storing sheets can cause difficulties in removing protective film and leave glue traces on the surface of the plates. In such cases, complaints on the remains of glue after protective film will not be included by the manufacturer.

- In the case of hidden fastening panels, pay attention that the foil is removed from the inside of the longer lock before assembly.

ATTENTION !!!

In the case of wall panels with visible fastening, the upper side of the panels in the package is a facade side, which should be paid special attention!

Maintenance and washingIn order to extend the durability period of roofs and facades made of coated sheets, they should be regularly controlled and preserved.

- Review -once a year (preferably in spring), a roof/facade review should be reviewed to detect any damage early.

- Cleaning sheet metal -roofs/facades made of coated sheet require cleaning at least once a year. Driving dirt can cause uneven discoloration of the color (result of uneven UV interaction), as well as to reduce corrosion resistance (dirt stops moisture on a baking tray gradually damaging it). Dodged and stained places can be cleaned with a soft brush and water (max. 60 ° C). If it is necessary, it is allowed to add a mild detergent to the water (pH 6 ÷ 7, max. 10% solution). Water under pressure (max. 100 bar) can also be used for cleaning, however, the water stream cannot be used too close to the surface of the plate (min. 30 cm), and it cannot be directed perpendicular to the surface. At the connectors, the water stream should be directed down to avoid entering the water under pressure into the gaps around the connectors. With old plate coatings, you should handle with exceptional caution. Washing should be carried out from top down and always cleaned place should be rinsed thoroughly with clean water.

- Do not use scrubbing powders, nitro solvents, chloride solutions, aromatic agents, as well as salmiak (ammonium chloride) or sodium salts.

- Damage -possible damage during the warranty period must be consulted with the roof/facade contractor and can only be performed with his written consent. Repair of damage on small surfaces is carried out with the help of varnishes for air -drying repairs, while painting large surfaces is, as a rule, only using special industrial paints adapted to renovation of coverings. The surface for painting should be limited only to the places requiring (scratches to the metal layer, corrosion focus, etc.). Preparation of the surface for painting should be made according to generally accepted rules. Always remove all traces of corrosion – preferably with special brushes or fine -grained sandpaper. Then the repaired surface needs to be thoroughly reproduced, degreased and cleaned. For degreasing the surface, you can use extraction gasoline or water with the addition of surface-leisure (preferably with the addition of 1-2% of the ammonia solution). The repaired zones can show color differences compared to the original colors of sheet metal due to the natural impact of atmospheric phenomena (aging of varnish under the influence of UV radiation).

- Note- during review, cleaning, maintenance and repair, it is absolutely necessary to observe the health and safety rules.

Pruszyński Sp. z o.o. He is not responsible for any accidents arising from the above -mentioned activities.

In order to extend the durability period of roofs and facades made of coated sheets, they should be regularly controlled and preserved.

- Review -once a year (preferably in spring), a roof/facade review should be reviewed to detect any damage early.

- Cleaning sheet metal -roofs/facades made of coated sheet require cleaning at least once a year. Driving dirt can cause uneven discoloration of the color (result of uneven UV interaction), as well as to reduce corrosion resistance (dirt stops moisture on a baking tray gradually damaging it). Dodged and stained places can be cleaned with a soft brush and water (max. 60 ° C). If it is necessary, it is allowed to add a mild detergent to the water (pH 6 ÷ 7, max. 10% solution). Water under pressure (max. 100 bar) can also be used for cleaning, however, the water stream cannot be used too close to the surface of the plate (min. 30 cm), and it cannot be directed perpendicular to the surface. At the connectors, the water stream should be directed down to avoid entering the water under pressure into the gaps around the connectors. With old plate coatings, you should handle with exceptional caution. Washing should be carried out from top down and always cleaned place should be rinsed thoroughly with clean water.

- Do not use scrubbing powders, nitro solvents, chloride solutions, aromatic agents, as well as salmiak (ammonium chloride) or sodium salts.

- Damage -possible damage during the warranty period must be consulted with the roof/facade contractor and can only be performed with his written consent. Repair of damage on small surfaces is carried out with the help of varnishes for air -drying repairs, while painting large surfaces is, as a rule, only using special industrial paints adapted to renovation of coverings. The surface for painting should be limited only to the places requiring (scratches to the metal layer, corrosion focus, etc.). Preparation of the surface for painting should be made according to generally accepted rules. Always remove all traces of corrosion – preferably with special brushes or fine -grained sandpaper. Then the repaired surface needs to be thoroughly reproduced, degreased and cleaned. For degreasing the surface, you can use extraction gasoline or water with the addition of surface-leisure (preferably with the addition of 1-2% of the ammonia solution). The repaired zones can show color differences compared to the original colors of sheet metal due to the natural impact of atmospheric phenomena (aging of varnish under the influence of UV radiation).

- Note- during review, cleaning, maintenance and repair, it is absolutely necessary to observe the health and safety rules.

Pruszyński Sp. z o.o. He is not responsible for any accidents arising from the above -mentioned activities.

Technical specification of the coating

Available colours

SILVER

SILVER METALLIC

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

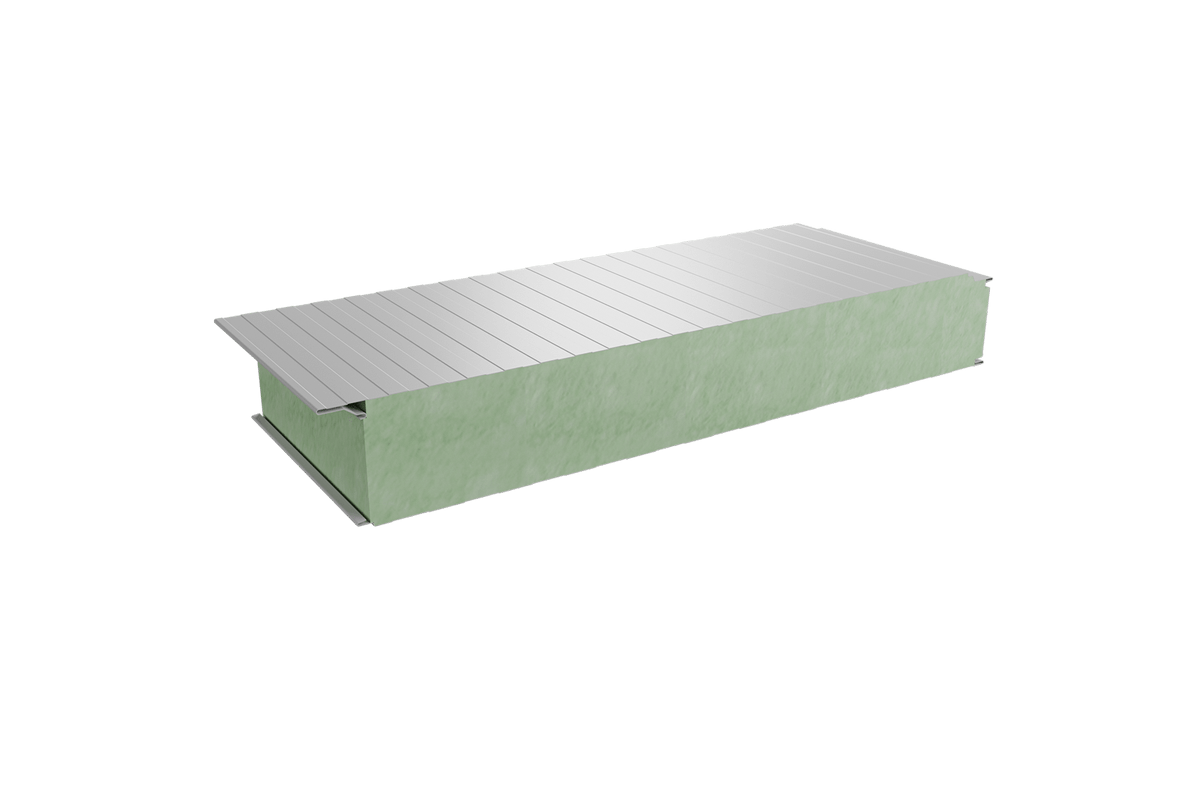

Product description

A wall plate with a core of mineral wool (PWS2-MW) is another, much more advanced generation of this product. Along with the introduction of a new generation, we have also expanded the product range available to customers, with a hidden lockboard (PWS2-MW-PL). What is very important, the new variant has been designed specifically for synergy with our other products, including a core with polyurethane foam core (PWS-PIR-ST, PWS-PIR-PL).

The use of dedicated hidden lock solutions as well as parameters allows you to easily combine both products on investments, giving greater flexibility in design and also achieving the desired physical parameters in specific segments of the building.