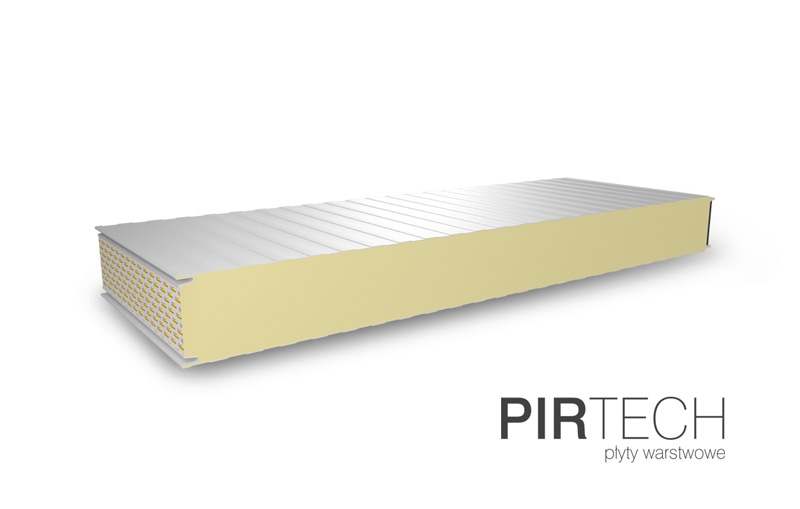

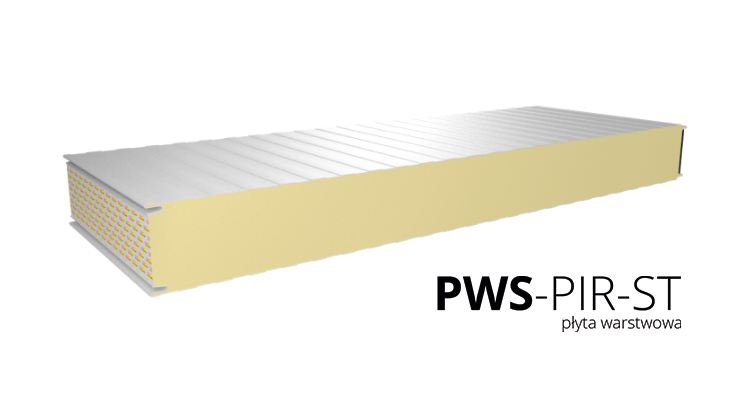

PWS-PIR-ST-120 - Wall sandwich panel - polyurethane foam - visible fastening

Panel with visible fastening PWS-PIR-ST-120

Technical specification

General information

* 1150 mm - standard module, 1019 mm - non -standard module

** Approximate mass masses are given for the thickness of the external sheets. 0.50mm and internal 0.40mm and standard module.

micro trapezoidal - M

wave - F

cassette - K

Physical properties

Below you will find the most important technical parameters of our products, necessary for using them in construction. If you are interested in other technical details or consulting our technical department, we encourage you to contact our contact form.

SIGNS:

*Heat transfer coefficient for the use of stainless steel fasteners, for galvanized steel, the value is 0.18W/m2K

** EI45 fire resistance concerns the use of an internal plate with a horizontal system.

Physical properties

EI30(o↔i)

--

as an internal wall/department

EI30

EI45*

Length of panels

Permissible panel lengths depending on the color of the cladding (minimum length - 2.5 MB).

group I (very bright colors)

18 m

group I (very bright colors)

12 m

SILVER

group III (dark colors)

9 m

SILVER METALLIC

Recommendations for the selection of plates in the context of thermal loadsDuring projecting it’s important to include difference in temperature of external and internal cladding of sandwich panels. Gradients of temperatues due to difference in external temperature T1 and internal temperature T2 are dependent on few factors:

Purpose of building (range of temperatures inside building T2)

localization of building – position due to sun

colour of external steel cladding (T1).

Depending on latitude, height above sea level and distance from sea on europe continent are use 4 different levels of winter temperature (T1 – external cladding):

0, -10oC,

0, -20oC, (for ex. Poland)

0, -30oC, (for ex. scandinavian countries)

Temperatures of external cladding of roof panel which is covered with snow layer is 0oC.

For calculation was assumed external temperature in winter of -20 oC.

Temperature of external cladding T1 has maximum value during summer and is depending of colour and grade of reflection of surface. Values T1, which are minmal for calculation bearing status (SGN) and are proper for calculations of limit status of use (SGU) are:

- Very brigth colours RG = 75-90 T1 = +55oC

- Brigth colours RG = 40-74 T1 = +65oC

- Dark colours RG = 8-39 T1 = +80oC

where RG – grade of reflextion in ratio of magnesium oxide = 100%

During projecting it’s important to include difference in temperature of external and internal cladding of sandwich panels. Gradients of temperatues due to difference in external temperature T1 and internal temperature T2 are dependent on few factors:

Purpose of building (range of temperatures inside building T2)

localization of building – position due to sun

colour of external steel cladding (T1).

Depending on latitude, height above sea level and distance from sea on europe continent are use 4 different levels of winter temperature (T1 – external cladding):

0, -10oC,

0, -20oC, (for ex. Poland)

0, -30oC, (for ex. scandinavian countries)

Temperatures of external cladding of roof panel which is covered with snow layer is 0oC.

For calculation was assumed external temperature in winter of -20 oC.

Temperature of external cladding T1 has maximum value during summer and is depending of colour and grade of reflection of surface. Values T1, which are minmal for calculation bearing status (SGN) and are proper for calculations of limit status of use (SGU) are:

- Very brigth colours RG = 75-90 T1 = +55oC

- Brigth colours RG = 40-74 T1 = +65oC

- Dark colours RG = 8-39 T1 = +80oC

where RG – grade of reflextion in ratio of magnesium oxide = 100%

Recommendations

Transport recommendationsRecommended ways of transport for sandwich panels:

- semi-trailer truck (tractor + trailer of length not longer than length of loaded panels) with open platform or trailer which enables loading from both sides on full length

- transportation belts should be assembled on panels max. each 3m, but not less than 2 belts for one package – tension strength of panels should be putted correctly to not damage panels

Recommended ways of transport for sandwich panels:

- semi-trailer truck (tractor + trailer of length not longer than length of loaded panels) with open platform or trailer which enables loading from both sides on full length

- transportation belts should be assembled on panels max. each 3m, but not less than 2 belts for one package – tension strength of panels should be putted correctly to not damage panels

Storage recommendationsSandwich panels should be storage maximum 2 packages one on another.

In below chart you can see what is maximal quantity of panels in one package.

thickness of panels

PWS-PIR-ST

40 mm

28 pcs.

50 mm

22 pcs.

60 mm

18 pcs.

80 mm

14 pcs.

100 mm

11 pcs.

120 mm

9 pcs.

- All packages should be storage on flat surface with possibility to discharging water.

- It is allowed to storage maximum 2 packages of panels with length up to 6m one on another, in case of packages with length higher than 6m these packages should be storage separately.

- During storage of panels on building site, packages should be protected against mechanical damages, UV rays, aggressive conditions(acids, fertilisers, salts and other corrosion factors), precipitations, strong wind etc.

- It’s recommended to storage packages under roof in ventilated facilities.

- Protective foil are used as additional protection of surface of panels from mechanical, stress, damages which may occur during transport or loading/unloading. However foils never dismiss from duty of correct protection of panels during storage.

- It’s recommended to remove foil before assembly of panels on elevation or roof. Removing of foil should be done during positive temperatues.

- Protective foil should be removed during 1 month of production date, even when panels are not assembled yet.

- Improper storage may cause difficulties when removing the protective foil and leave glue marks, in this case complaints won’t be accepted by Producer.

- In case of panels with hidden fix, there should paid attention that foil is removed from inside longer lock before assembly.

ATTENTION !!!

In case of panels with visible fix(PIR-ST), upper side of package is elevation side, which is very important.

Sandwich panels should be storage maximum 2 packages one on another.

In below chart you can see what is maximal quantity of panels in one package.

| thickness of panels | PWS-PIR-ST |

|---|---|

| 40 mm | 28 pcs. |

| 50 mm | 22 pcs. |

| 60 mm | 18 pcs. |

| 80 mm | 14 pcs. |

| 100 mm | 11 pcs. |

| 120 mm | 9 pcs. |

- All packages should be storage on flat surface with possibility to discharging water.

- It is allowed to storage maximum 2 packages of panels with length up to 6m one on another, in case of packages with length higher than 6m these packages should be storage separately.

- During storage of panels on building site, packages should be protected against mechanical damages, UV rays, aggressive conditions(acids, fertilisers, salts and other corrosion factors), precipitations, strong wind etc.

- It’s recommended to storage packages under roof in ventilated facilities.

- Protective foil are used as additional protection of surface of panels from mechanical, stress, damages which may occur during transport or loading/unloading. However foils never dismiss from duty of correct protection of panels during storage.

- It’s recommended to remove foil before assembly of panels on elevation or roof. Removing of foil should be done during positive temperatues.

- Protective foil should be removed during 1 month of production date, even when panels are not assembled yet.

- Improper storage may cause difficulties when removing the protective foil and leave glue marks, in this case complaints won’t be accepted by Producer.

- In case of panels with hidden fix, there should paid attention that foil is removed from inside longer lock before assembly.

ATTENTION !!!

In case of panels with visible fix(PIR-ST), upper side of package is elevation side, which is very important.

MaintenanceIn order to extend durability of roofs and elevations it’s recommended to check and conservative it.

- Inspection – One time a year (it’s best in spring) there should be inspection of roof/elevation in order to early detection of possible damage.

- Cleaning of steel sheet – Roof and elevation made of steel sheets require cleaning at least once a year. Stratifying dirt on steel sheet may cause uneven discoloration of lacquer (because of uneven impact of UV beams), and lower protection to corrosion(dust traps humidity on steel sheets which causes damage). Dirty and stained spots can be cleaned by soft brush and water (temp. max. 60c). If it is necessary it is permitted to use some light detergent (ph 6/7, max 10% solution). There also can be used pressed water(max. 100bar) to cleaning, however the beam of water cannot be applicated too near of surface of sheets(min. 30 cm), also it shouldn’t be perpendicularly to surface. Near the connections water beam should be directed to bottom, to avoid water of entering cracks near connections. With old surfaces of steel sheets we should deal with high cautiously. Cleaning should be conducted from top to bottom, and cleaned spots should be rinsed out immediately.

- It is not permitted to use scouring powders, nitro solvent, chlorine liquor, aromatised substances, substances with Amon chloride or sodium.

- Damages – Possible damages during guarantee should be consulted with Contractor of roof/elevation and can be repaired only with his written permission.Repair of damages on small surfaces is done with quick-drying varnish. However painting big surfaces should be done with special industrial paints to renovating coverings. Painting should be limited only to special damaged spots (scratches to steel, centres of corrosion etc.)Preparation of surface to painting should be done with generally accepted rules. It is necessary to precisely remove all signs of corrosion – best with special brush or close-grained sandpaper. Then that surface should be undusted, degreased and cleaned. To degrease extraction naptha or water with addition of surfactant(best with 1-2%solution of ammoniac) can be used. Repaired spots may be different in colour compared to original steel sheets because of natural impact of atmospheric phenomenon (ageing of varnish due to impact of UV radiation)

- ATTENTION!– During inspecting, cleaning, conservation and repair all work safety regulations should be obeyed.Pruszyński Sp. z o.o. is not in charge of possible accidents during carrying out all following actions.

In order to extend durability of roofs and elevations it’s recommended to check and conservative it.

- Inspection – One time a year (it’s best in spring) there should be inspection of roof/elevation in order to early detection of possible damage.

- Cleaning of steel sheet – Roof and elevation made of steel sheets require cleaning at least once a year. Stratifying dirt on steel sheet may cause uneven discoloration of lacquer (because of uneven impact of UV beams), and lower protection to corrosion(dust traps humidity on steel sheets which causes damage). Dirty and stained spots can be cleaned by soft brush and water (temp. max. 60c). If it is necessary it is permitted to use some light detergent (ph 6/7, max 10% solution). There also can be used pressed water(max. 100bar) to cleaning, however the beam of water cannot be applicated too near of surface of sheets(min. 30 cm), also it shouldn’t be perpendicularly to surface. Near the connections water beam should be directed to bottom, to avoid water of entering cracks near connections. With old surfaces of steel sheets we should deal with high cautiously. Cleaning should be conducted from top to bottom, and cleaned spots should be rinsed out immediately.

- It is not permitted to use scouring powders, nitro solvent, chlorine liquor, aromatised substances, substances with Amon chloride or sodium.

- Damages – Possible damages during guarantee should be consulted with Contractor of roof/elevation and can be repaired only with his written permission.Repair of damages on small surfaces is done with quick-drying varnish. However painting big surfaces should be done with special industrial paints to renovating coverings. Painting should be limited only to special damaged spots (scratches to steel, centres of corrosion etc.)Preparation of surface to painting should be done with generally accepted rules. It is necessary to precisely remove all signs of corrosion – best with special brush or close-grained sandpaper. Then that surface should be undusted, degreased and cleaned. To degrease extraction naptha or water with addition of surfactant(best with 1-2%solution of ammoniac) can be used. Repaired spots may be different in colour compared to original steel sheets because of natural impact of atmospheric phenomenon (ageing of varnish due to impact of UV radiation)

- ATTENTION!– During inspecting, cleaning, conservation and repair all work safety regulations should be obeyed.Pruszyński Sp. z o.o. is not in charge of possible accidents during carrying out all following actions.

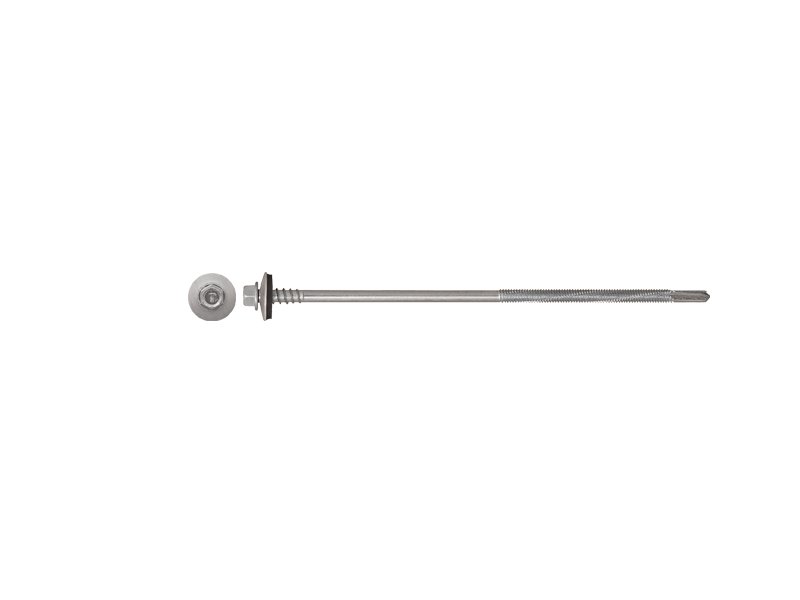

Elementy składowe

Technical specification of the coating

Available colours

SILVER

SILVER METALLIC

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Product description

Panel with visible fastening

PIRTECH wall panels Standard wall (visible mounting) with a maximum modular width of 1150 mm allow for simple and quick installation to various types of structures using appropriate through fasteners. The uniquely designed longitudinal contacts (locks) of the pen and wpust, ensure very good tightness, fire resistance and quick assembly.