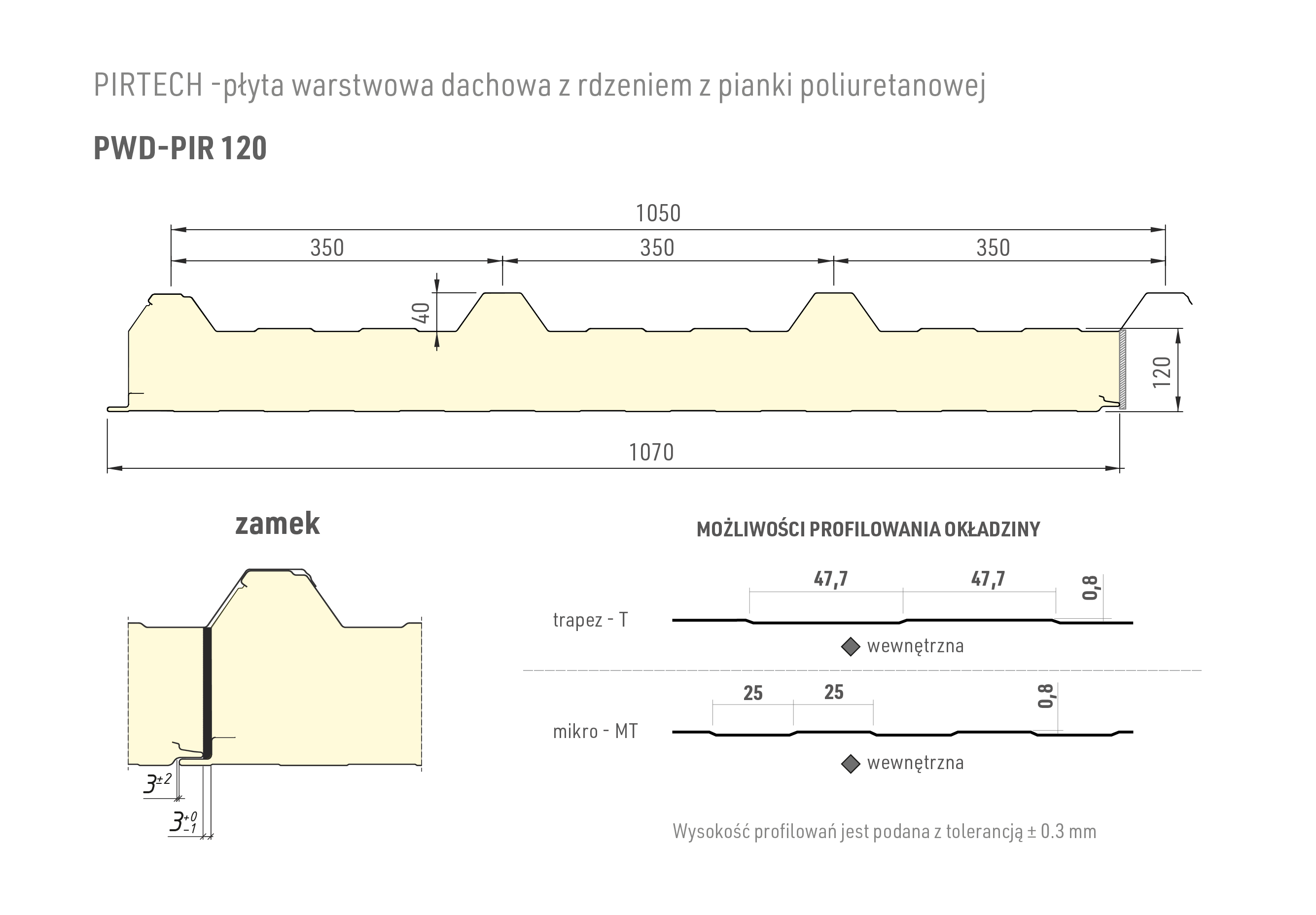

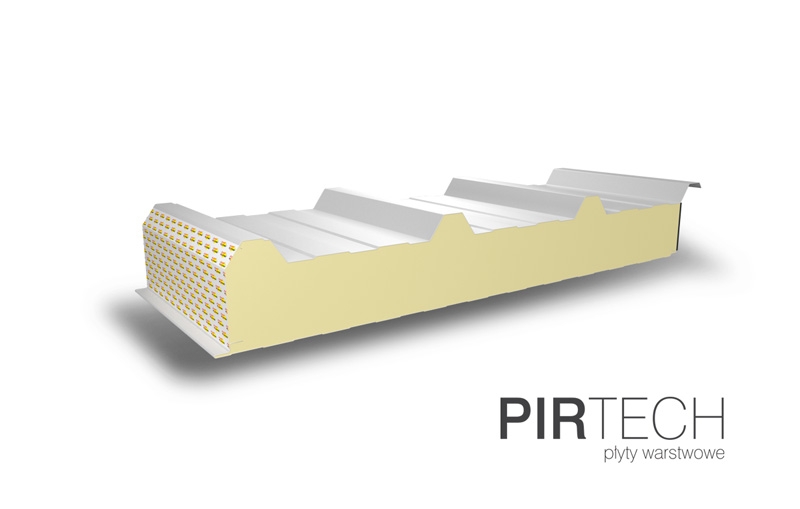

PWD -PIR -120 - ROOF Sandwich panel - Polyurethane foam - visible fastening

Technical specification

General information

micro - M

Physical properties

Length of panels

Permissible panel lengths depending on the color of the cladding (minimum length - 2.5 MB).

group I (very bright colors)

18 m

group II (bright colors)

15 m

SILVER

group III (dark colors)

12 m

SILVER METALLIC

* The colors marked with the star are not available in the standard offer. Please direct individual queries in terms of colors using the contact form.

Read more below.

Recommendations for the selection of plates in the context of thermal loadsDuring projecting it’s important to include difference in temperature of external and internal cladding of sandwich panels.Gradients of temperatues due to difference in external temperature T1 and internal temperature T2 are dependent on few factors:

Purpose of building (range of temperatures inside building T2)

localization of building – position due to sun

colour of external steel cladding (T1).

Depending on latitude, height above sea level and distance from sea on europe continent are use 4 different levels of winter temperature (T1 – external cladding):

0, -10oC,

0, -20oC, (for ex. Poland)

0, -30oC, (for ex. scandinavian countries)

Temperatures of external cladding of roof panel which is covered with snow layer is 0oC.

For calculation was assumed external temperature in winter of -20 oC.

Temperature of external cladding T1 has maximum value during summer and is depending of colour and grade of reflection of surface. Values T1, which are minmal for calculation bearing status (SGN) and are proper for calculations of limit status of use (SGU) are:

- Very brigth colours RG = 75-90 T1 = +55oC

- Brigth colours RG = 40-74 T1 = +65oC

- Dark colours RG = 8-39 T1 = +80oC

where RG – grade of reflextion in ratio of magnesium oxide = 100%

During projecting it’s important to include difference in temperature of external and internal cladding of sandwich panels.Gradients of temperatues due to difference in external temperature T1 and internal temperature T2 are dependent on few factors:

Purpose of building (range of temperatures inside building T2)

localization of building – position due to sun

colour of external steel cladding (T1).

Depending on latitude, height above sea level and distance from sea on europe continent are use 4 different levels of winter temperature (T1 – external cladding):

0, -10oC,

0, -20oC, (for ex. Poland)

0, -30oC, (for ex. scandinavian countries)

Temperatures of external cladding of roof panel which is covered with snow layer is 0oC.

For calculation was assumed external temperature in winter of -20 oC.

Temperature of external cladding T1 has maximum value during summer and is depending of colour and grade of reflection of surface. Values T1, which are minmal for calculation bearing status (SGN) and are proper for calculations of limit status of use (SGU) are:

- Very brigth colours RG = 75-90 T1 = +55oC

- Brigth colours RG = 40-74 T1 = +65oC

- Dark colours RG = 8-39 T1 = +80oC

where RG – grade of reflextion in ratio of magnesium oxide = 100%

Recommendations

Transport i składowanie

- W przypadku odbioru własnym środkiem transportu, samochód powinien posiadać otwartą platformę załadunkową umożliwiającą swobodny załadunek jak i rozładunek.

- Rozładunek “ręczny” powinien być przeprowadzony przez odpowiednią liczbę osób tzn. przy długich arkuszach (ok. 6 mb) powinno uczestniczyć 6 osób, po 3 z każdej strony, zwracając szczególną uwagę, aby nie przesuwać po sobie blach, nie odginać bocznych krawędzi oraz ich nie rozciągać. Deformacja blach podczas rozładunku i przenoszenia powoduje późniejsze problemy z ich prawidłowym montażem (szpary na zamkach).

- Najodpowiedniejszy jest rozładunek w opakowaniach producenta przy użyciu urządzeń mechanicznych.

- Na placu budowy arkusze powinny byś składowane w fabrycznym opakowaniu, pod zadaszeniem. Magazynowanie w takich warunkach nie powinno trwać dłużej niż 3 tygodnie od daty produkcji. Po tym czasie opakowanie należy rozciąć, a arkusze przełożyć przekładkami umożliwiającymi swobodną cyrkulację powietrza. Maksymalny czas magazynowania nie powinien być dłuższy niż 6 miesięcy licząc od daty produkcji pod rygorem utraty gwarancji.

- Folie ochronne stosowane są, aby dodatkowo zabezpieczyć blachy powlekane przed uszkodzeniami mechanicznymi, naprężeniami i uderzeniami mogącymi wystąpić w czasie transportu, przeładunku czy profilowania. Folie ochronne nigdy nie zwalniają z obowiązku właściwego zabezpieczenia blach podczas magazynowania ani przed szkodliwym działaniem czynników chemicznych podczas procesu ich przetwarzania. Zaleca się stopniowe usuwanie folii z gotowych profili, element po elemencie, przed zamocowaniem elementów ściennych i dachowych na budynku. Usunięcie folii ochronnej z powierzchni blachy powinno nastąpić w ciągu trzech tygodni od daty wyprodukowania blachy jeśli towar przechowywany jest we właściwy sposób, tj. z zachowaniem dodatniej temperatury, braku dużej wilgotności, bez bezpośredniego działania promieni słonecznych. Brak zachowania odpowiednich warunków przechowywania towaru może skrócić czas usuwania folii do trzech dni licząc od daty dostawy towaru.

- Niewłaściwy sposób składowania może powodować utrudnienia w usuwaniu folii ochronnej oraz pozostawiać na arkuszach ślady po kleju.

- W przypadku odbioru własnym środkiem transportu, samochód powinien posiadać otwartą platformę załadunkową umożliwiającą swobodny załadunek jak i rozładunek.

- Rozładunek “ręczny” powinien być przeprowadzony przez odpowiednią liczbę osób tzn. przy długich arkuszach (ok. 6 mb) powinno uczestniczyć 6 osób, po 3 z każdej strony, zwracając szczególną uwagę, aby nie przesuwać po sobie blach, nie odginać bocznych krawędzi oraz ich nie rozciągać. Deformacja blach podczas rozładunku i przenoszenia powoduje późniejsze problemy z ich prawidłowym montażem (szpary na zamkach).

- Najodpowiedniejszy jest rozładunek w opakowaniach producenta przy użyciu urządzeń mechanicznych.

- Na placu budowy arkusze powinny byś składowane w fabrycznym opakowaniu, pod zadaszeniem. Magazynowanie w takich warunkach nie powinno trwać dłużej niż 3 tygodnie od daty produkcji. Po tym czasie opakowanie należy rozciąć, a arkusze przełożyć przekładkami umożliwiającymi swobodną cyrkulację powietrza. Maksymalny czas magazynowania nie powinien być dłuższy niż 6 miesięcy licząc od daty produkcji pod rygorem utraty gwarancji.

- Folie ochronne stosowane są, aby dodatkowo zabezpieczyć blachy powlekane przed uszkodzeniami mechanicznymi, naprężeniami i uderzeniami mogącymi wystąpić w czasie transportu, przeładunku czy profilowania. Folie ochronne nigdy nie zwalniają z obowiązku właściwego zabezpieczenia blach podczas magazynowania ani przed szkodliwym działaniem czynników chemicznych podczas procesu ich przetwarzania. Zaleca się stopniowe usuwanie folii z gotowych profili, element po elemencie, przed zamocowaniem elementów ściennych i dachowych na budynku. Usunięcie folii ochronnej z powierzchni blachy powinno nastąpić w ciągu trzech tygodni od daty wyprodukowania blachy jeśli towar przechowywany jest we właściwy sposób, tj. z zachowaniem dodatniej temperatury, braku dużej wilgotności, bez bezpośredniego działania promieni słonecznych. Brak zachowania odpowiednich warunków przechowywania towaru może skrócić czas usuwania folii do trzech dni licząc od daty dostawy towaru.

- Niewłaściwy sposób składowania może powodować utrudnienia w usuwaniu folii ochronnej oraz pozostawiać na arkuszach ślady po kleju.

Konserwacja i mycie

- W celu przedłużenia okresu trwałości dachów i elewacji wykonanych z blach powlekanych należy regularnie je kontrolować i konserwować.

- Przegląd – Raz w roku (najlepiej wiosną) należy dokonać przeglądu dachu/elewacji w celu wczesnego wykrycia ewentualnych uszkodzeń.

- Czyszczenie blachy – Dachy/elewacje wykonywane z blachy powlekanej wymagają czyszczenia co najmniej raz w roku. Osadzający się na blasze brud może spowodować nierównomierne odbarwianie się koloru (wynik nierównomiernego oddziaływania promieni UV), a także do zmniejszenia odporności na korozję (brud zatrzymuje wilgoć na blasze stopniowo ją uszkadzając). Zabrudzone i poplamione miejsca mogą być czyszczone przy pomocy miękkiej szczotki i wody (temp. max. 60°C). Jeśli jest to konieczne dopuszcza się dodanie do wody łagodnego detergentu (pH 6÷7, max. 10% roztwór). Do czyszczenia może być także użyta woda pod ciśnieniem (max. 100 bar), jednakże strumień wody nie może być stosowany zbyt blisko powierzchni arkusza (min. 30 cm), a także nie może być skierowany prostopadle do powierzchni . Przy łącznikach strumień wody powinien być skierowany ku dołowi tak, aby uniknąć wnikania wody pod ciśnieniem w szczeliny wokół łączników. Ze starymi powłokami należy obchodzić się z wyjątkową ostrożnością. Mycie należy przeprowadzać od góry ku dołowi i zawsze oczyszczone miejsce należy niezwłocznie dokładnie opłukać czystą wodą.

- Nie wolno stosować proszków do szorowania, rozpuszczalników nitro, roztworów chlorowych, aromatycznych środków, jak również środków zawierających salmiak (chlorek amonu) lub sole sodowe.

- Uszkodzenia – Naprawianie ewentualnych uszkodzeń w trakcie trwania okresu gwarancji powinno być konsultowane z Wykonawcą dachu/elewacji i może być wykonywane tylko za jego aprobatą. Naprawa szkód na małych powierzchniach odbywa się przy pomocy lakierów do napraw, schnących na powietrzu. Malowanie dużych powierzchni jest z zasady możliwe tylko za pomocą specjalnych farb przemysłowych dostosowanych do renowacji pokryć. Powierzchnię do malowania należy ograniczyć tylko do miejsc tego wymagających (zadrapania do warstwy metalu, ogniska korozji itp.). Przygotowanie powierzchni do malowania należy wykonać wg ogólnie przyjętych zasad. Należy zawsze dokładnie usunąć wszelkie ślady korozji – najlepiej za pomocą specjalnych szczotek lub drobnoziarnistego papieru ściernego. Następnie trzeba naprawianą powierzchnię dokładnie odpylić, odtłuścić i oczyścić. Do odtłuszczenia powierzchni można użyć benzyny ekstrakcyjnej lub wody z dodatkiem środków powierzchniowo-czynnych (najlepiej z dodatkiem 1-2% roztworu amoniaku). Naprawiane strefy mogą wykazywać różnice w kolorze w porównaniu z oryginalnymi kolorami blach z powodu naturalnego oddziaływania zjawisk atmosferycznych (starzenie się lakieru pod wpływem działania promieniowania UV).

- Nie wolno stosować blach stalowych powlekanych organicznie w:

- środowisku o stałym kontakcie z wodą o dużym stopniu zasolenia,

- kontakcie z chemią budowlaną, w tym beton, tynk, mokre drewno itp.,

- w środowisku narażonym na występowanie agresywnych chemikaliów

- połączeniu z materiałami o innym potencjale elektrochemicznym

- UWAGA– W trakcie przeglądu, czyszczenia, konserwacji i napraw należy bezwzględnie przestrzegać zasad BHP.

- Firma Pruszyński Sp. z o.o. nie odpowiada za ewentualne wypadki powstałe w wynikuwykonywania powyższych czynności

- W celu przedłużenia okresu trwałości dachów i elewacji wykonanych z blach powlekanych należy regularnie je kontrolować i konserwować.

- Przegląd – Raz w roku (najlepiej wiosną) należy dokonać przeglądu dachu/elewacji w celu wczesnego wykrycia ewentualnych uszkodzeń.

- Czyszczenie blachy – Dachy/elewacje wykonywane z blachy powlekanej wymagają czyszczenia co najmniej raz w roku. Osadzający się na blasze brud może spowodować nierównomierne odbarwianie się koloru (wynik nierównomiernego oddziaływania promieni UV), a także do zmniejszenia odporności na korozję (brud zatrzymuje wilgoć na blasze stopniowo ją uszkadzając). Zabrudzone i poplamione miejsca mogą być czyszczone przy pomocy miękkiej szczotki i wody (temp. max. 60°C). Jeśli jest to konieczne dopuszcza się dodanie do wody łagodnego detergentu (pH 6÷7, max. 10% roztwór). Do czyszczenia może być także użyta woda pod ciśnieniem (max. 100 bar), jednakże strumień wody nie może być stosowany zbyt blisko powierzchni arkusza (min. 30 cm), a także nie może być skierowany prostopadle do powierzchni . Przy łącznikach strumień wody powinien być skierowany ku dołowi tak, aby uniknąć wnikania wody pod ciśnieniem w szczeliny wokół łączników. Ze starymi powłokami należy obchodzić się z wyjątkową ostrożnością. Mycie należy przeprowadzać od góry ku dołowi i zawsze oczyszczone miejsce należy niezwłocznie dokładnie opłukać czystą wodą.

- Nie wolno stosować proszków do szorowania, rozpuszczalników nitro, roztworów chlorowych, aromatycznych środków, jak również środków zawierających salmiak (chlorek amonu) lub sole sodowe.

- Uszkodzenia – Naprawianie ewentualnych uszkodzeń w trakcie trwania okresu gwarancji powinno być konsultowane z Wykonawcą dachu/elewacji i może być wykonywane tylko za jego aprobatą. Naprawa szkód na małych powierzchniach odbywa się przy pomocy lakierów do napraw, schnących na powietrzu. Malowanie dużych powierzchni jest z zasady możliwe tylko za pomocą specjalnych farb przemysłowych dostosowanych do renowacji pokryć. Powierzchnię do malowania należy ograniczyć tylko do miejsc tego wymagających (zadrapania do warstwy metalu, ogniska korozji itp.). Przygotowanie powierzchni do malowania należy wykonać wg ogólnie przyjętych zasad. Należy zawsze dokładnie usunąć wszelkie ślady korozji – najlepiej za pomocą specjalnych szczotek lub drobnoziarnistego papieru ściernego. Następnie trzeba naprawianą powierzchnię dokładnie odpylić, odtłuścić i oczyścić. Do odtłuszczenia powierzchni można użyć benzyny ekstrakcyjnej lub wody z dodatkiem środków powierzchniowo-czynnych (najlepiej z dodatkiem 1-2% roztworu amoniaku). Naprawiane strefy mogą wykazywać różnice w kolorze w porównaniu z oryginalnymi kolorami blach z powodu naturalnego oddziaływania zjawisk atmosferycznych (starzenie się lakieru pod wpływem działania promieniowania UV).

- Nie wolno stosować blach stalowych powlekanych organicznie w:

- środowisku o stałym kontakcie z wodą o dużym stopniu zasolenia,

- kontakcie z chemią budowlaną, w tym beton, tynk, mokre drewno itp.,

- w środowisku narażonym na występowanie agresywnych chemikaliów

- połączeniu z materiałami o innym potencjale elektrochemicznym

- UWAGA– W trakcie przeglądu, czyszczenia, konserwacji i napraw należy bezwzględnie przestrzegać zasad BHP.

- Firma Pruszyński Sp. z o.o. nie odpowiada za ewentualne wypadki powstałe w wynikuwykonywania powyższych czynności

Technical specification of the coating

Available colours

SILVER

SILVER METALLIC

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Product description

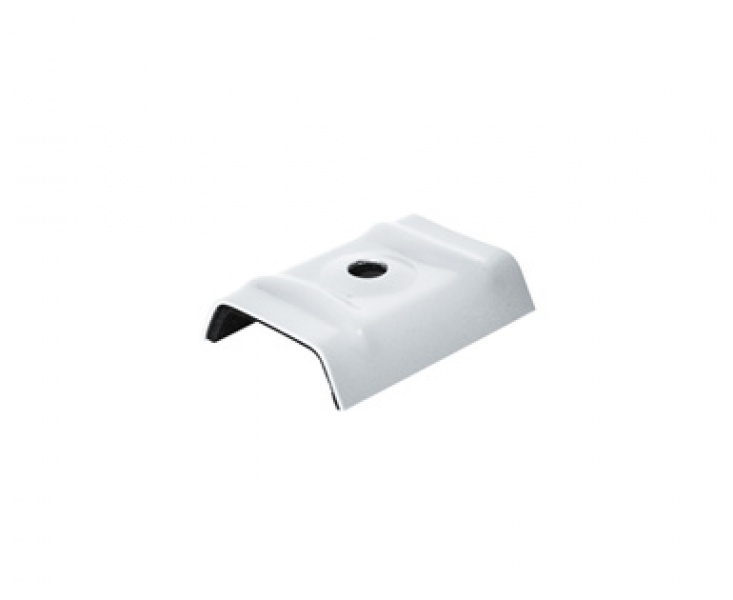

Panel with visible fastening

PIRTECH ROOK (visible mounting) boards with a maximum modular width of 1050 mm allow for simple and quick installation to various types of structures with the help of Kalotka and appropriate through fasteners.

The uniquely designed longitudinal contacts (locks) of the pen and wpust ensure very good tightness, fire resistance and quick assembly. The shape of the outer surface (trapezoidal profile) allows you to carry high loads as well as can be used in single -span and multi -span systems

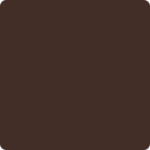

When connecting roof slabs in length, it is necessary to cut the upper plate, i.e. the plate from the ridge side.

Pirtech roof plates can be produced with ready undercut in the range from mins 50 to max 300 mm.

Just choose the type of undercut (see Fig.), Which is determined by the direction of assembly:

- Left undercut – assembly from the left

- right undercut– assembly from the right

The undercut length can be: D = 50, 100, 150, 200, 250 and max 300 mm.

Note: The total length of the plate contains the selected undercut length regardless of its size.

For example, a 6000 mm long plate with a undercut of 200 mm = 6000 mm (5800 mm core + 200 mm sheet).

Blachy Pruszyński performs two types of undercuts:

– full undercut, i.e. an internal sheet cut, tape on the outer trapezoidal cladding, undercutting of foam along the entire thickness of the plate core,

– incomplete undercut, i.e. cutting the inner sheet, undercutting of foam along the entire thickness of the core of the plate.

Individual undercut widths (regarding the range only from 50 to 300 mm) are possible, but without a tape on the outer – trapezoidal cladding with undercut of foam along the entire thickness of the core of the plates.

For PWD-PIR 40, 60, 80, 100, 120 min. The length of the plates with full undercut is 5,000 mm. Plates in lengths below 5,000 mm can only be made without a tape on the outer – trapezoidal cladding.

For PWD-PIR panels 160 min. The minimum length of the panels with full undercut is 4,000 mm. The PWD -PIR 160 board in a length of below 4,000 mm can only be made without a tape on the outer – trapezoidal cladding.