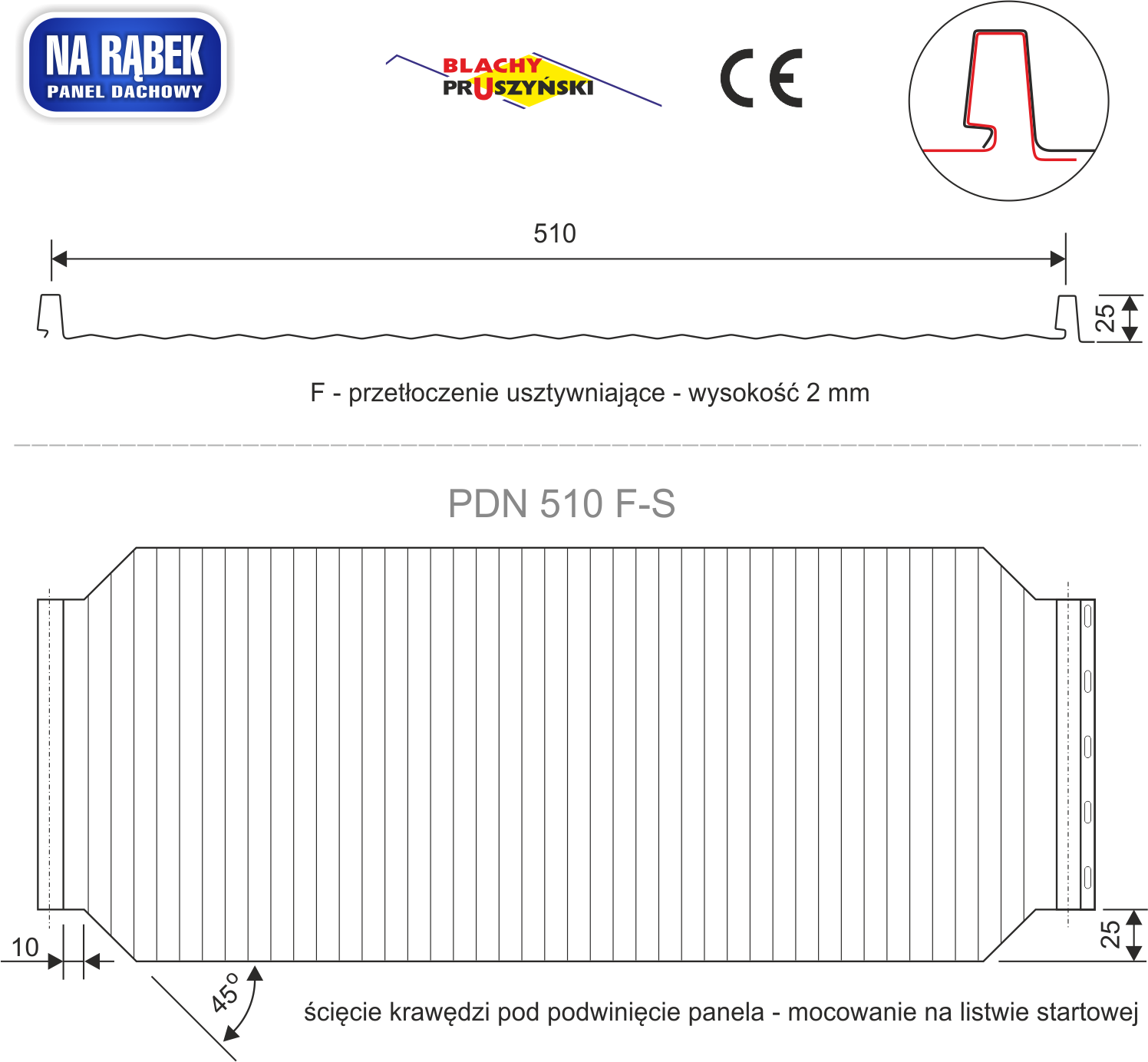

Panel PD510 F-S

Technical specification

General information

Installation : roof panels for seams should be mounted at positive temperatures. Pruszyński sheets allow a different assembly method, consistent with roofing art.

Effective width

Seam high

Material

Recommendations

Panels storagePackages should be stored in dry and well-ventilated spaces, without humidity condensation between the sheets. Collective packages should be put on blocks about 20cm height upon the surface. If panels are stored more than 3 weeks from the production date – panels should be checked and separators should be put between to allow for free air circulation. All information about the way and period of storage are on the protective foil, product labels and our catalogues, assembly instructions and website.

Packages should be stored in dry and well-ventilated spaces, without humidity condensation between the sheets. Collective packages should be put on blocks about 20cm height upon the surface. If panels are stored more than 3 weeks from the production date – panels should be checked and separators should be put between to allow for free air circulation. All information about the way and period of storage are on the protective foil, product labels and our catalogues, assembly instructions and website.

Protective foilProtective foil is used to safe the roof panels against mechanical damages. It should be removed directly at the assembly stage and it should protect panels against humidity and sun during the storage period. Non compliance with above rules may cause difficulties when removing the foil from sheets and dirty after the glue.

Protective foil is used to safe the roof panels against mechanical damages. It should be removed directly at the assembly stage and it should protect panels against humidity and sun during the storage period. Non compliance with above rules may cause difficulties when removing the foil from sheets and dirty after the glue.

MaintanceGenerally, roofs with standing seam panels do not demand any special maintenance. Nevertheless, so as to prevent the risk of to fast damaging of the building and regardless the localization, wall covering and roof covering must be checked and maintenanced once a year, at least. Deposit, industrial dust (from lime plants, cement limes, foundries and mines) which cause damage of varnish cover as a result of chemical reaction with water and leafs, which cause fading of organic cover due to rotting should be removed from panel surface. Any lack in covering should be cleaned and painted with special touch-up paints.

Generally, roofs with standing seam panels do not demand any special maintenance. Nevertheless, so as to prevent the risk of to fast damaging of the building and regardless the localization, wall covering and roof covering must be checked and maintenanced once a year, at least. Deposit, industrial dust (from lime plants, cement limes, foundries and mines) which cause damage of varnish cover as a result of chemical reaction with water and leafs, which cause fading of organic cover due to rotting should be removed from panel surface. Any lack in covering should be cleaned and painted with special touch-up paints.

Final warnings1. Special electric vibrating scissors or irregular, nibblers and hand scissors should be used to cut sheet. Tools which cause damage of varnish and galvanized covering due to the produced heat when cutting the steel are forbidden, for instance angle grinder.

2. You can walk on the roof with shoes with soft bottom, make steps in the bottom of waves, on patches. Before you start walking on the roof, all the screws must be assembled.

3. Small damages of covering from assembly could be painted with touch-up paints. The surface must be cleaned from dirt and oil.

4. Steel chips from the cutting or drilling must be removed with soft brush – its rusting may damage the steel surface.

5. Dirt, which stays after assembler work or dirt from daily exploitation should be removed with normal cleaning agents.

6. Use of any steel treatments (including chimney cap, rainwater cleaner, etc.) from copper sheets on roofs and elevations from galvanized and covered sheets is forbidden.

1. Special electric vibrating scissors or irregular, nibblers and hand scissors should be used to cut sheet. Tools which cause damage of varnish and galvanized covering due to the produced heat when cutting the steel are forbidden, for instance angle grinder.

2. You can walk on the roof with shoes with soft bottom, make steps in the bottom of waves, on patches. Before you start walking on the roof, all the screws must be assembled.

3. Small damages of covering from assembly could be painted with touch-up paints. The surface must be cleaned from dirt and oil.

4. Steel chips from the cutting or drilling must be removed with soft brush – its rusting may damage the steel surface.

5. Dirt, which stays after assembler work or dirt from daily exploitation should be removed with normal cleaning agents.

6. Use of any steel treatments (including chimney cap, rainwater cleaner, etc.) from copper sheets on roofs and elevations from galvanized and covered sheets is forbidden.

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Product description

Panel with standing seam

Sheets on the so -called Standing seam is one of the oldest technologies used in construction.

Now we can propose a modern solution in the traditional shape of sheets with standing sheet metal for years.

The edge finish option with cut edges enabling assembly on the start strip.

Tags

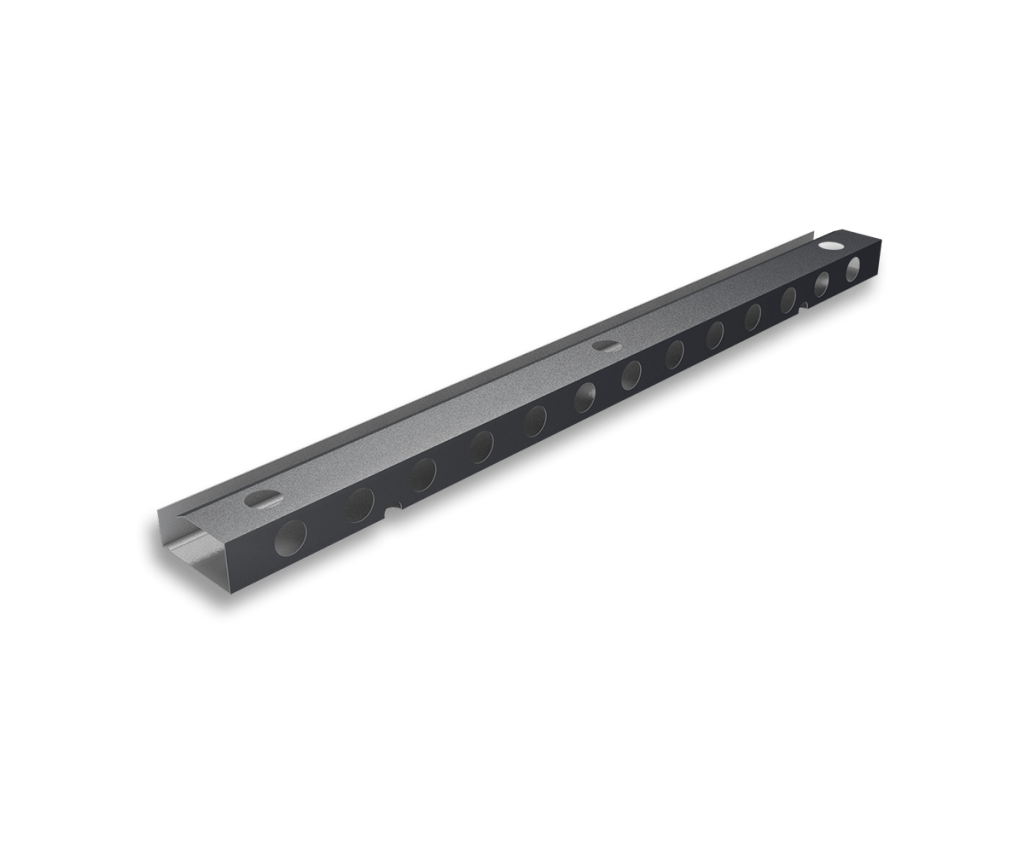

See our offer of accessories

Choose the best accessories for your roof!

TORX self-drilling screws (staples)

TORX self-drilling screws (staples)