TP-7 trapezoidal soffit without perforation

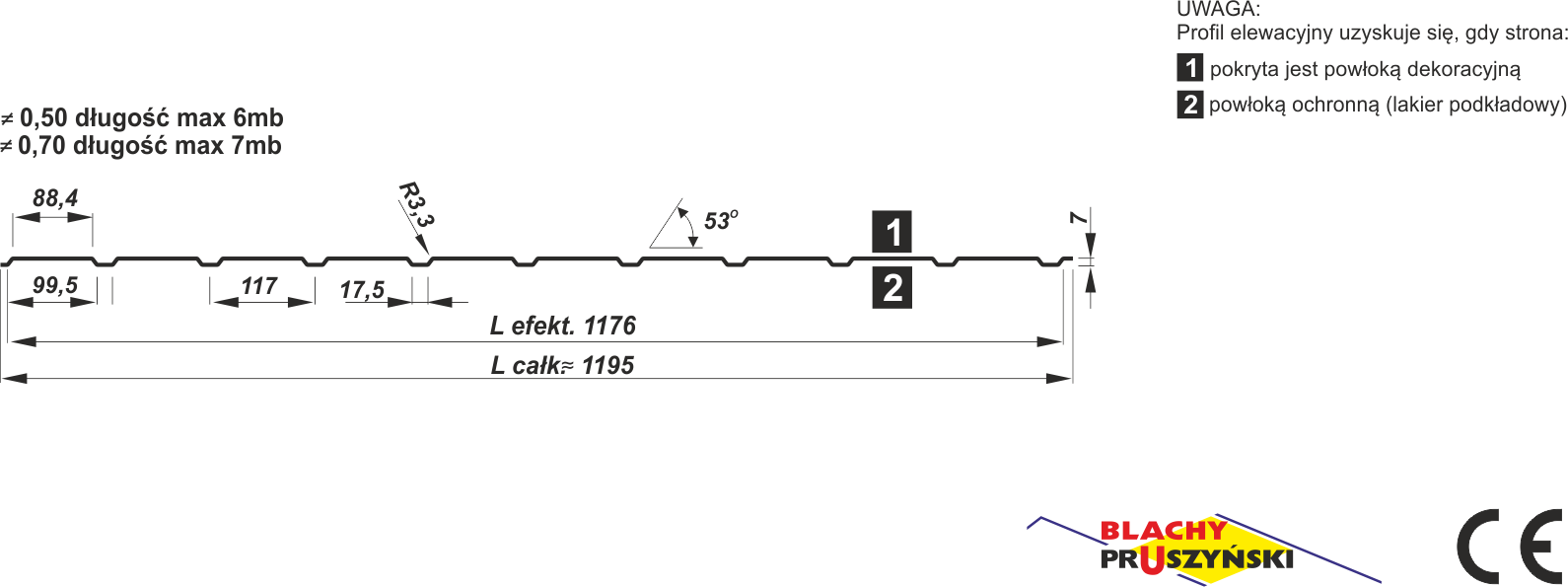

Technical specification

General information

Recommendations

Transport and storage

- In the event of receiving its own means of transport, the car should have an open loading platform for free loading and unloading.

- On the construction site, panels should be stored in the factory packaging, under the roof. Storage in such conditions should not last longer than 3 weeks from the date of production. After this time, the packaging should be cut, and the sheets should be transferred to spacers enabling free air circulation. The maximum storage time should not be longer than 6 months from the date of production under pain of loss of warranty.

- Protective films are used to additionally protect coated sheets against mechanical damage, stresses and impacts that can occur during transport, transhipment or profiling. Protective films never release from the obligation to properly protect sheets during storage or against the harmful effects of chemical factors during the processing process. It is recommended to gradually remove the foil from ready profiles, element by element, shortly before the wall and roof elements on the building.

- Incorrect storage method can cause difficulties in removing protective film and leave glue marks on the sheets.

- In the event of receiving its own means of transport, the car should have an open loading platform for free loading and unloading.

- On the construction site, panels should be stored in the factory packaging, under the roof. Storage in such conditions should not last longer than 3 weeks from the date of production. After this time, the packaging should be cut, and the sheets should be transferred to spacers enabling free air circulation. The maximum storage time should not be longer than 6 months from the date of production under pain of loss of warranty.

- Protective films are used to additionally protect coated sheets against mechanical damage, stresses and impacts that can occur during transport, transhipment or profiling. Protective films never release from the obligation to properly protect sheets during storage or against the harmful effects of chemical factors during the processing process. It is recommended to gradually remove the foil from ready profiles, element by element, shortly before the wall and roof elements on the building.

- Incorrect storage method can cause difficulties in removing protective film and leave glue marks on the sheets.

Maintenance and washing

- In order to extend the durability period of roofs and facades made of coated sheets, they should be regularly controlled and preserved.

- Review – Once a year (preferably in spring), you should review the roof/facade to detect any damage early.

- Cleaning sheet metal – roofs/facades made of coated sheet require cleaning at least once a year. Driving dirt can cause uneven discoloration of the color (result of uneven UV interaction), as well as to reduce corrosion resistance (dirt stops moisture on a baking tray gradually damaging it). Dodged and stained places can be cleaned with a soft brush and water (max. 60 ° C). If it is necessary, it is allowed to add a mild detergent to the water (pH 6 ÷ 7, max. 10% solution). Water under pressure (max. 100 bar) can also be used for cleaning, however, the water stream cannot be used too close to the surface of the sheet (min. 30 cm), and it cannot be directed perpendicular to the surface. At the connectors, the water stream should be directed down to avoid entering the water under pressure into the gaps around the connectors. With old coatings, you should handle with exceptional caution. Washing should be carried out from top down and always cleaned place should be rinsed thoroughly with clean water.

- You can’t use scrubbing powders, Nitro solvents, chlorine solutions, aromatic agents, as well as salmiak (ammonium chloride) or sodium salts.

- Damage – Repairing any damage during the warranty period should be consulted with the roof/facade contractor and can only be performed with its approval. Repair of damage on small surfaces is carried out with the help of repair varnishes, drying in the air. Painting large surfaces is, as a rule, only using special industrial paints adapted to renovation of coverings. The surface for painting should be limited only to the places requiring (scratches to the metal layer, corrosion focus, etc.). Preparation of the surface for painting should be made according to generally accepted rules. Always remove all traces of corrosion – preferably with special brushes or fine -grained sandpaper. Then the repaired surface needs to be thoroughly reproduced, degreased and cleaned. For degreasing the surface, you can use extraction gasoline or water with the addition of surface-leisure (preferably with the addition of 1-2% of the ammonia solution). The repaired zones can show differences in color compared to the original colors of sheet metal due to the natural impact of atmospheric phenomena (aging of varnish under the influence of UV radiation).

- You can’t use organically coated steel sheets in:

- Environment with constant contact with a high degree of salinity,

- Contact with construction chemistry, including concrete, plaster, wet wood, etc.,

- In an environment exposed to aggressive chemicals

- Connection with materials with a different electrochemical potential

- ATTENTION – During review, cleaning, maintenance and repairs, it is absolutely necessary to follow health and safety rules

- Firma Pruszyński Sp. z o.o. is not responsible for any accidents arising from the performance of the above activities.

- In order to extend the durability period of roofs and facades made of coated sheets, they should be regularly controlled and preserved.

- Review – Once a year (preferably in spring), you should review the roof/facade to detect any damage early.

- Cleaning sheet metal – roofs/facades made of coated sheet require cleaning at least once a year. Driving dirt can cause uneven discoloration of the color (result of uneven UV interaction), as well as to reduce corrosion resistance (dirt stops moisture on a baking tray gradually damaging it). Dodged and stained places can be cleaned with a soft brush and water (max. 60 ° C). If it is necessary, it is allowed to add a mild detergent to the water (pH 6 ÷ 7, max. 10% solution). Water under pressure (max. 100 bar) can also be used for cleaning, however, the water stream cannot be used too close to the surface of the sheet (min. 30 cm), and it cannot be directed perpendicular to the surface. At the connectors, the water stream should be directed down to avoid entering the water under pressure into the gaps around the connectors. With old coatings, you should handle with exceptional caution. Washing should be carried out from top down and always cleaned place should be rinsed thoroughly with clean water.

- You can’t use scrubbing powders, Nitro solvents, chlorine solutions, aromatic agents, as well as salmiak (ammonium chloride) or sodium salts.

- Damage – Repairing any damage during the warranty period should be consulted with the roof/facade contractor and can only be performed with its approval. Repair of damage on small surfaces is carried out with the help of repair varnishes, drying in the air. Painting large surfaces is, as a rule, only using special industrial paints adapted to renovation of coverings. The surface for painting should be limited only to the places requiring (scratches to the metal layer, corrosion focus, etc.). Preparation of the surface for painting should be made according to generally accepted rules. Always remove all traces of corrosion – preferably with special brushes or fine -grained sandpaper. Then the repaired surface needs to be thoroughly reproduced, degreased and cleaned. For degreasing the surface, you can use extraction gasoline or water with the addition of surface-leisure (preferably with the addition of 1-2% of the ammonia solution). The repaired zones can show differences in color compared to the original colors of sheet metal due to the natural impact of atmospheric phenomena (aging of varnish under the influence of UV radiation).

- You can’t use organically coated steel sheets in:

- Environment with constant contact with a high degree of salinity,

- Contact with construction chemistry, including concrete, plaster, wet wood, etc.,

- In an environment exposed to aggressive chemicals

- Connection with materials with a different electrochemical potential

- ATTENTION – During review, cleaning, maintenance and repairs, it is absolutely necessary to follow health and safety rules

- Firma Pruszyński Sp. z o.o. is not responsible for any accidents arising from the performance of the above activities.

Colouristic:

The following colors may differ from reality.

PMG 35 um

The Pruszyński company guarantees the implementation of a individual order in the same color (shade) each time. However, due to the complexity of coating processes, it is possible to occur in shades between individual supplies.

Liability for color is therefore limited to one delivery.

In connection with the above, in the case of placing sheets to a specific party, please indicate on the order or inform the trader that this is a continuation of the order and delivery of a color sample.

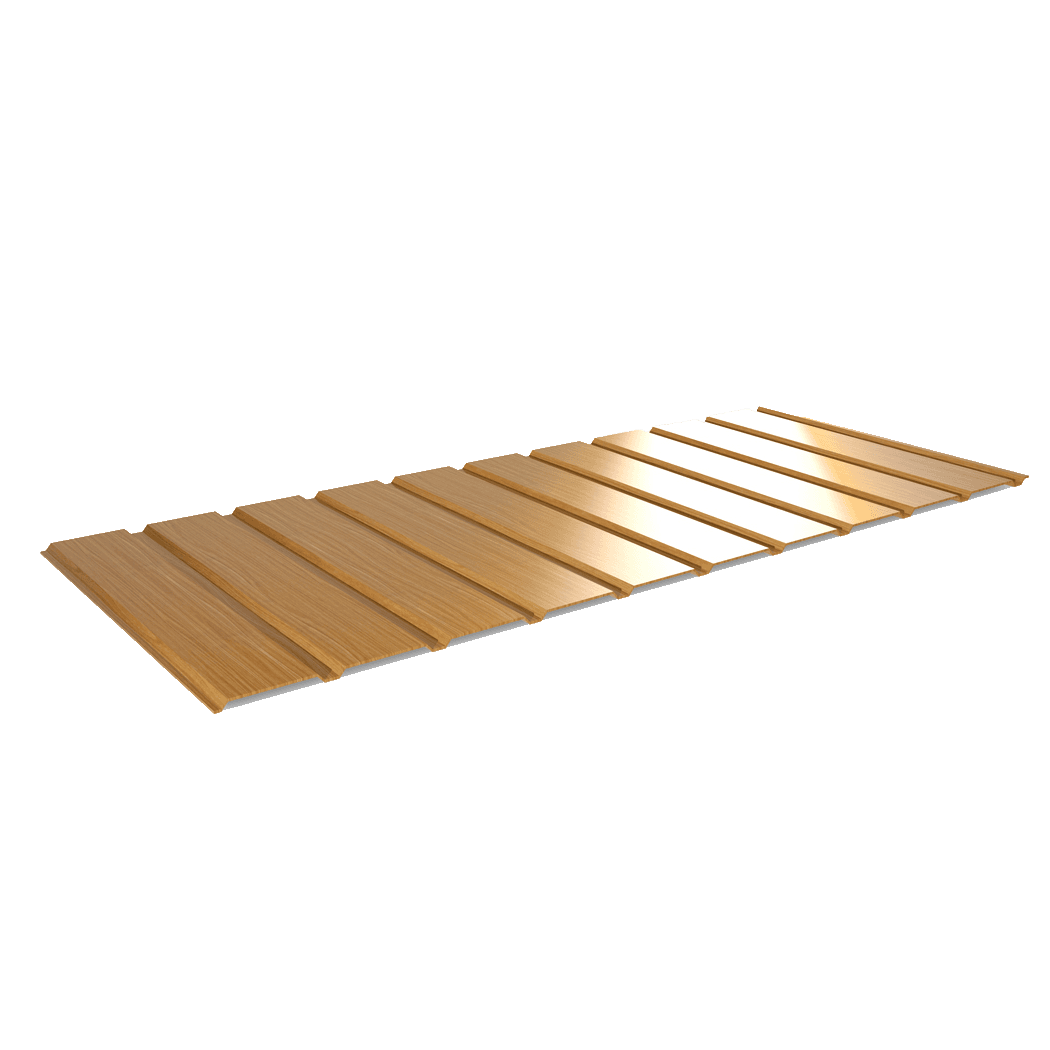

Product description

Soffit made of trapezoidal sheet

The soffit plays an aesthetic as well as stiffening and protective role in relation to the roofing.

The soffit definitely improves the appearance of roofing, but above all plays an important role in protecting the roof against weather conditions and animal invasion. The use of sheet metal soffit carries a number of advantages:

- Possibility to choose the color perfectly for the color of the coverage

- no waving and better stiffness than plastic

- Resistance to aging and discoloration

- Simplicity of assembly – possibility of ordering to size

The Pruszyński Blachy offer includes two types of soffits. TP-7P trapezoida TP-7P z perforacją oraz TP-7P bez perforacji. Podbitka z blachy trapezowej jest wykonana z najwyższej jakości blachy, zabezpieczonej cynkowo i pokrytej lakierem ochronnym. Specjalnie ze względu na zastosowanie i by dodatkowo poprawić aspekt estetyczny podbitki są dostępne w powłokach imitujących drewno takich jak GWood Oak Gold® (Złoty Dąb) czy Orzech, które zarówno fakturą jak i kolorystyką do złudzenia przypominają elementy drewniane.