Ren - Modular roof tile - panel

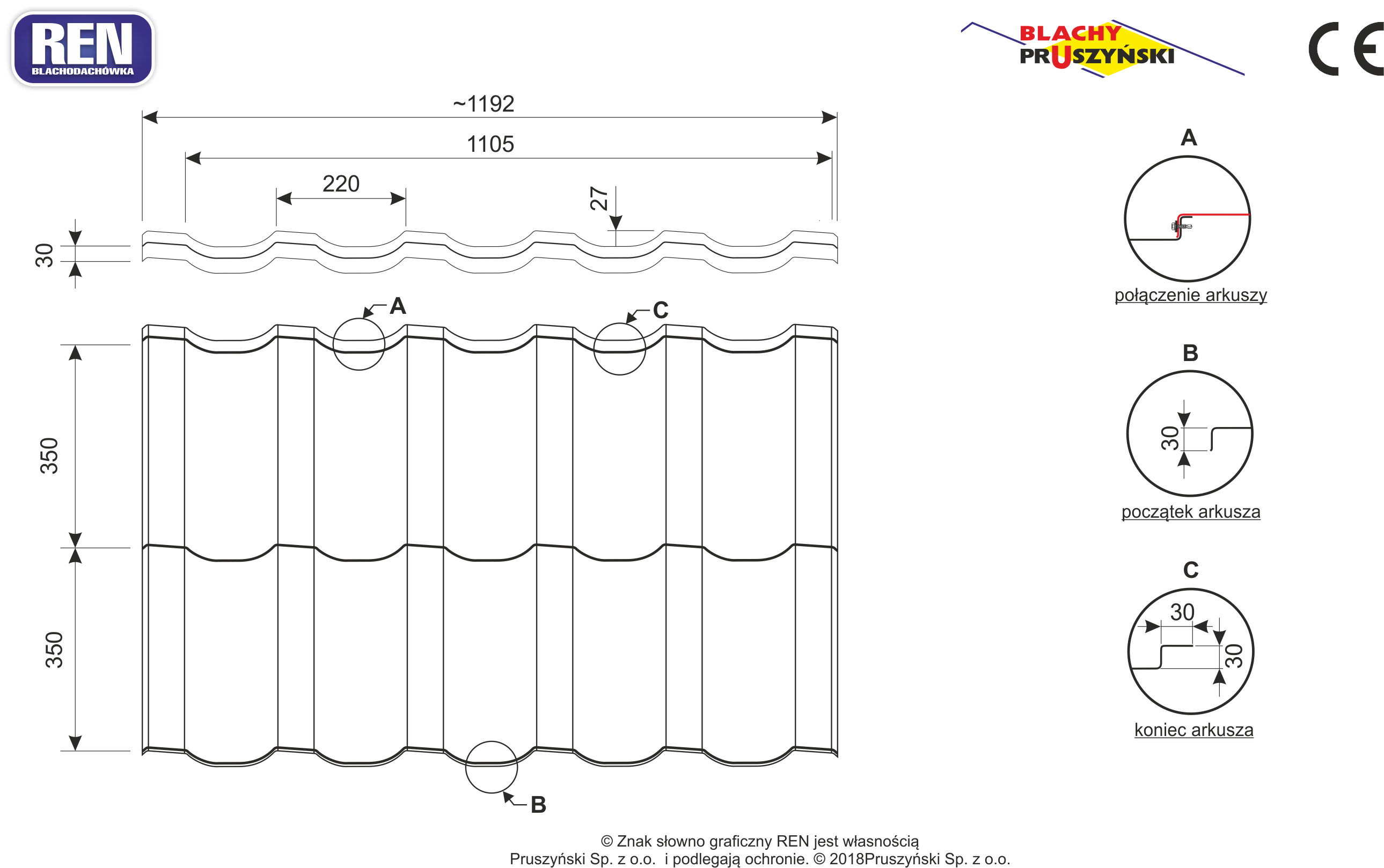

Technical specification

General information

The panels are mounted classically like the other panel roof tiles in the Blachy Pruszyński offer. REN is available in all coatings from our offer in 27 basic colors from the RAL and RR palette.

Recommendations

Transport and storage

- It is of course the best to unload in original manufacturer packaging, using mechanical unloading equipment.

- Unloading shall be carried out by the proper number of people, that is in the case of long sheets (ca. 6 linear metre) the sheets shall be unloaded by 6 people, three on each side. Special attention shall be paid not to friction one sheet against one another, bend the side edges or stretch the sheet. Steel sheet deformation during the unloading and moving can result in problems with proper installation (chinks in clamps).

- Galvanised and aluzinc steel sheets must be protected against getting wet!

- If the customer collects the product with his own means of transportation, the vehicle shall have an open loading platform allowing for easy loading and unloading, with the length suitable for ordered sheets. The sheets shall not extend beyond the platform. Proper anchoring of the sheet packages for the transport will reduce the damage of the sheet paint coat due to abrasion.

- It is of course the best to unload in original manufacturer packaging, using mechanical unloading equipment.

- Unloading shall be carried out by the proper number of people, that is in the case of long sheets (ca. 6 linear metre) the sheets shall be unloaded by 6 people, three on each side. Special attention shall be paid not to friction one sheet against one another, bend the side edges or stretch the sheet. Steel sheet deformation during the unloading and moving can result in problems with proper installation (chinks in clamps).

- Galvanised and aluzinc steel sheets must be protected against getting wet!

- If the customer collects the product with his own means of transportation, the vehicle shall have an open loading platform allowing for easy loading and unloading, with the length suitable for ordered sheets. The sheets shall not extend beyond the platform. Proper anchoring of the sheet packages for the transport will reduce the damage of the sheet paint coat due to abrasion.

Maintenance and washing

- In order to extend durability of roofs and elevations it’s recommended to check and conserve it.

- Inspection – One time a year (best in spring) there should be inspection of roof/elevation for early detection of possible damage.

- Cleaning of steel sheet – Roof and elevation made of steel sheets require cleaning at least once a year. Stratifying dirt on steel sheet may cause uneven discoloration of lacquer (because of uneven impact of UV beams), and lower protection to corrosion(dust traps humidity on steel sheets which causes damage). Dirty and stained spots can be cleaned by soft brush and water (temp. max. 60c). If it is necessary it is permitted to use some light detergent (ph 6/7, max 10% solution). There also can be used pressed water(max. 100bar) to cleaning, however the beam of water cannot be applicated too near of surface of sheets(min. 30 cm), also it shouldn’t be perpendicularly to surface. Near the connections water beam should be directed to bottom, to avoid water of entering cracks near connections. With old surfaces of steel sheets we should deal with high cautiously. Cleaning should be conducted from top to bottom, and cleaned spots should be rinsed out immediately.

- It is not permitted to use scouring powders, nitro solvent, chlorine liquor, aromatised substances, substances with amon chloride or sodium.

- Damages – Possible damages during guarantee should be consulted with Contractor of roof/elevation and can be repaired only with his written permission.Repair of damages on small surfaces is done with quick-drying varnish. However painting big surfaces should be done with special industrial paints dedicated to renovating coverings. Painting should be limited only to special damaged spots (scratches to steel, centres of corrosion etc.)Preparation of surface to painting should be done with generally accepted rules. It is necessary to precisely remove all signs of corrosion – best with special brush or close-grained sandpaper. Then that surface should be undusted, degreased and cleaned. To degrease extraction naptha or water with addition of surfactant(best with 1-2%solution of ammoniac) can be used. Repaired spots may be different in colour compared to original steel sheets because of natural impact of atmospheric phenomenon (ageing of varnish due to impact of UV radiation)

- ATTENTION!– During inspecting, cleaning, conservation and repair all work safety regulations should be obeyed.Pruszyński Sp. z o.o. is not in charge of possible accidents during carrying out all following actions.

- In order to extend durability of roofs and elevations it’s recommended to check and conserve it.

- Inspection – One time a year (best in spring) there should be inspection of roof/elevation for early detection of possible damage.

- Cleaning of steel sheet – Roof and elevation made of steel sheets require cleaning at least once a year. Stratifying dirt on steel sheet may cause uneven discoloration of lacquer (because of uneven impact of UV beams), and lower protection to corrosion(dust traps humidity on steel sheets which causes damage). Dirty and stained spots can be cleaned by soft brush and water (temp. max. 60c). If it is necessary it is permitted to use some light detergent (ph 6/7, max 10% solution). There also can be used pressed water(max. 100bar) to cleaning, however the beam of water cannot be applicated too near of surface of sheets(min. 30 cm), also it shouldn’t be perpendicularly to surface. Near the connections water beam should be directed to bottom, to avoid water of entering cracks near connections. With old surfaces of steel sheets we should deal with high cautiously. Cleaning should be conducted from top to bottom, and cleaned spots should be rinsed out immediately.

- It is not permitted to use scouring powders, nitro solvent, chlorine liquor, aromatised substances, substances with amon chloride or sodium.

- Damages – Possible damages during guarantee should be consulted with Contractor of roof/elevation and can be repaired only with his written permission.Repair of damages on small surfaces is done with quick-drying varnish. However painting big surfaces should be done with special industrial paints dedicated to renovating coverings. Painting should be limited only to special damaged spots (scratches to steel, centres of corrosion etc.)Preparation of surface to painting should be done with generally accepted rules. It is necessary to precisely remove all signs of corrosion – best with special brush or close-grained sandpaper. Then that surface should be undusted, degreased and cleaned. To degrease extraction naptha or water with addition of surfactant(best with 1-2%solution of ammoniac) can be used. Repaired spots may be different in colour compared to original steel sheets because of natural impact of atmospheric phenomenon (ageing of varnish due to impact of UV radiation)

- ATTENTION!– During inspecting, cleaning, conservation and repair all work safety regulations should be obeyed.Pruszyński Sp. z o.o. is not in charge of possible accidents during carrying out all following actions.

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Technical specification of the coating

Available colours

Pruszyński Company guarantess realization of each order in one colour shade. Although due to technological process of covering paint to steel shets there is possibility for occuring difference in colour shade in different deliveries.

Regarding this please inform sales person if different delivery is continuation of previous orders.

Product description

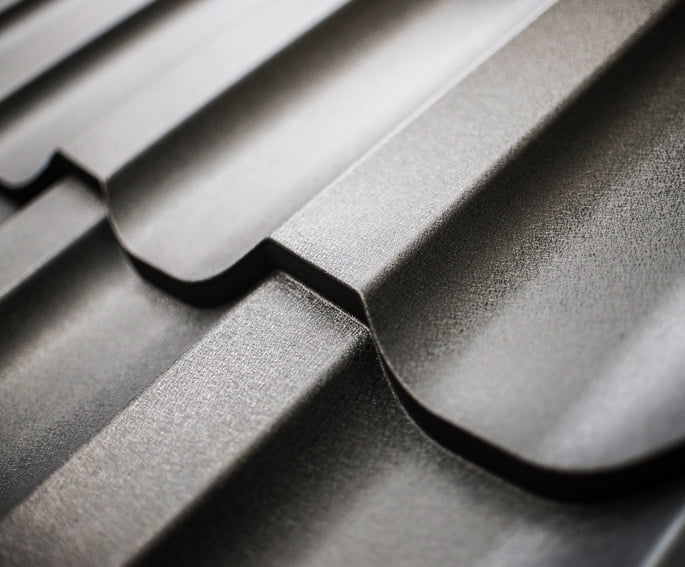

Roofing tile with character

Ren metal roof tile is the first sloping metal roof tile (cross section).

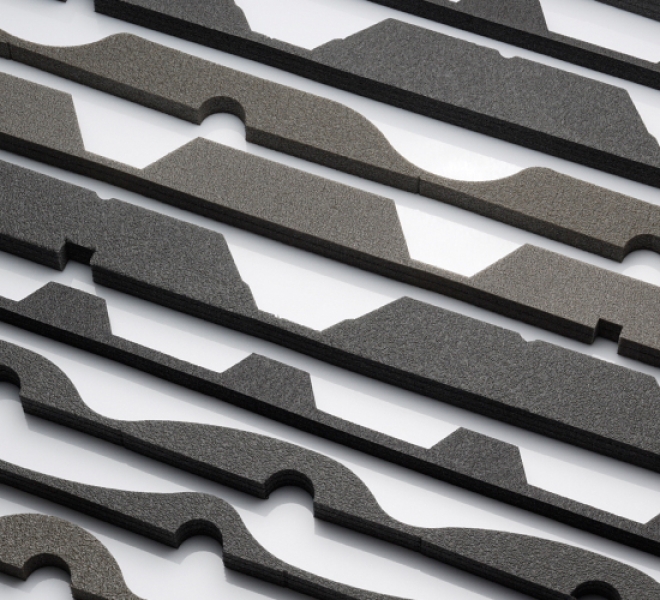

The shape of the covering provides a less tendency to deposit impurities, and a large corrosive protection palette (organic and metallic coatings) enable the use of RENE metal roofing sheets in places with high atmospheric aggressiveness in terms of corrosion.

Tags

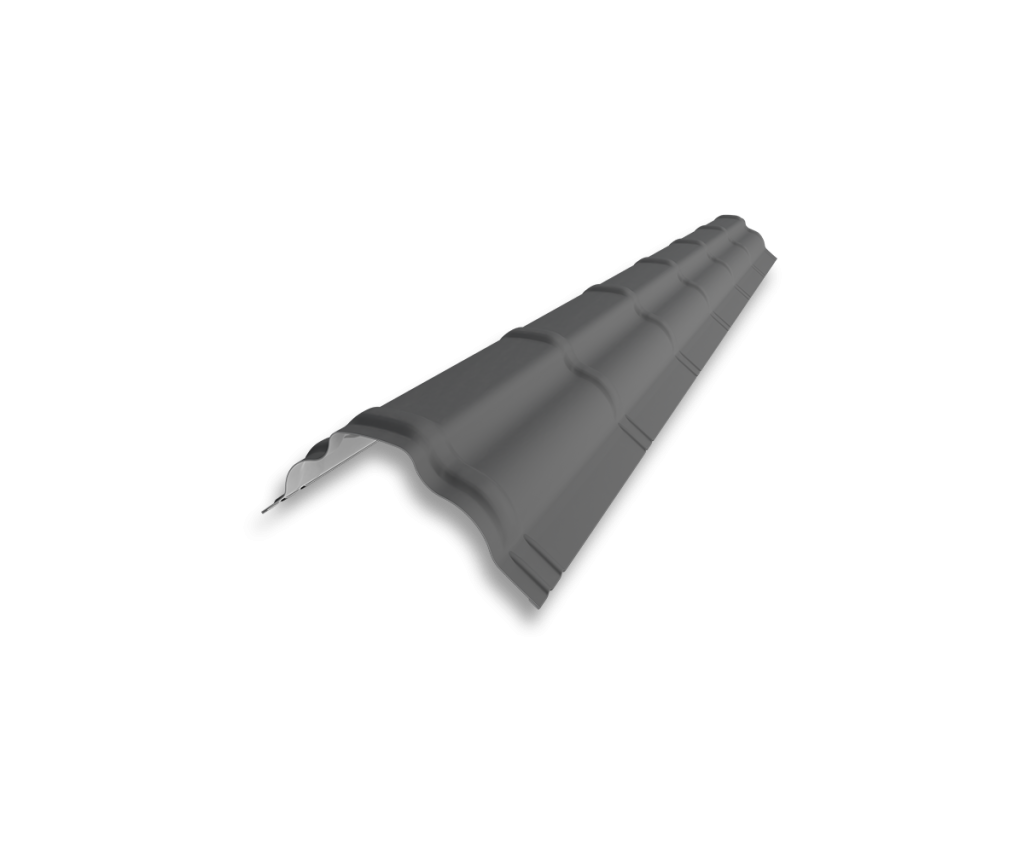

See our offer of accessories

Choose the best accessories for your roof!