Profiles Z - construction profiles

Technical specification

General information

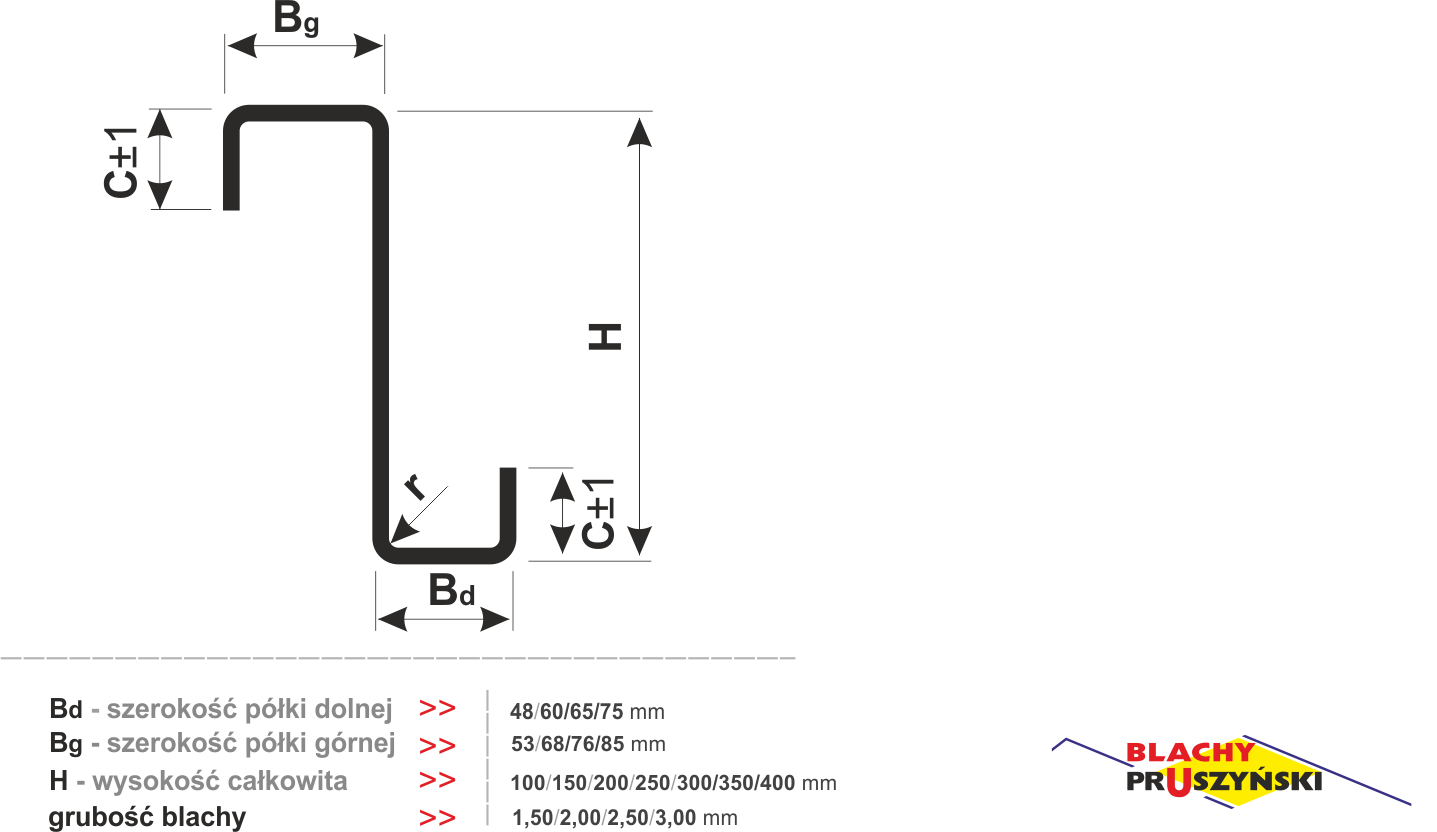

Product profile

| PROFIL Z | thickness | weight | H | Bd | Bg | C |

|---|---|---|---|---|---|---|

| mm | kg/m | mm | mm | mm | mm | |

| Z 100 | 1,50 | 2,64 | 100 | 48 | 53 | 16 |

| 2,00 | 3,52 | 100 | 48 | 53 | 16 | |

| 2,50 | 4,40 | 100 | 48 | 55 | 16 | |

| 3,00 | 5,28 | 100 | 48 | 55 | 16 | |

| 3,50* | 6,16 | 100 | 47 | 56 | 16 | |

| Z 100 | 1,50 | 3,00 | 100 | 60 | 68 | 16 |

| 2,00 | 4,00 | 100 | 60 | 68 | 16 | |

| 2,50 | 5,00 | 100 | 60 | 68 | 16 | |

| 3,00 | 6,00 | 100 | 60 | 68 | 16 | |

| 3,50* | 7,00 | 100 | 60 | 70 | 16 | |

| Z 150 | 1,50 | 3,24 | 150 | 48 | 53 | 21 |

| 2,00 | 4,32 | 150 | 48 | 53 | 21 | |

| 2,50 | 5,40 | 150 | 48 | 55 | 21 | |

| 3,00 | 6,48 | 150 | 48 | 55 | 21 | |

| 3,50* | 7,56 | 150 | 47 | 56 | 21 | |

| Z 150 | 1,50 | 3,60 | 150 | 60 | 68 | 21 |

| 2,00 | 4,80 | 150 | 60 | 68 | 21 | |

| 2,50 | 6,00 | 150 | 60 | 68 | 21 | |

| 3,00 | 7,20 | 150 | 60 | 68 | 21 | |

| 3,50* | 8,40 | 150 | 60 | 68 | 21 | |

| Z 180 | 1,50 | 3,96 | 180 | 60 | 68 | 21 |

| 2,00 | 5,28 | 180 | 60 | 68 | 21 | |

| 2,50 | 6,60 | 180 | 60 | 68 | 21 | |

| 3,00 | 7,92 | 180 | 60 | 68 | 21 | |

| 3,50* | 9,24 | 180 | 60 | 70 | 21 | |

| Z 200 | 1,50 | 3,84 | 200 | 48 | 53 | 21 |

| 2,00 | 5,12 | 200 | 48 | 53 | 21 | |

| 2,50 | 6,40 | 200 | 48 | 55 | 21 | |

| 3,00 | 7,68 | 200 | 48 | 55 | 21 | |

| 3,50* | 8,50 | 200 | 47 | 56 | 21 | |

| Z 200 | 1,50 | 4,20 | 200 | 60 | 68 | 21 |

| 2,00 | 5,60 | 200 | 60 | 68 | 21 | |

| 2,50 | 7,00 | 200 | 60 | 68 | 21 | |

| 3,00 | 8,40 | 200 | 60 | 68 | 21 | |

| 3,50* | 9,80 | 200 | 60 | 68 | 21 | |

| Z 250 | 1,50 | 4,80 | 250 | 60 | 68 | 21 |

| 2,00 | 6,40 | 250 | 60 | 68 | 21 | |

| 2,50 | 8,00 | 250 | 60 | 68 | 21 | |

| 3,00 | 9,60 | 250 | 60 | 68 | 21 | |

| 3,50* | 11,20 | 250 | 60 | 68 | 21 | |

| Z 250 | 1,50 | 4,97 | 250 | 65 | 75 | 21 |

| 2,00 | 6,62 | 250 | 65 | 75 | 21 | |

| 2,50 | 8,24 | 250 | 65 | 75 | 21 | |

| 3,00 | 9,89 | 250 | 65 | 75 | 21 | |

| 3,50* | 11,54 | 250 | 65 | 75 | 21 | |

| Z 300 | 1,50 | 5,69 | 300 | 65 | 75 | 21 |

| 2,00 | 7,58 | 300 | 65 | 75 | 21 | |

| 2,50 | 9,32 | 300 | 65 | 75 | 21 | |

| 3,00 | 11,18 | 300 | 65 | 75 | 21 | |

| 3,50* | 13,04 | 300 | 65 | 75 | 21 | |

| Z 350 | 1,50 | 6,24 | 350 | 65 | 75 | 21 |

| 2,00 | 8,32 | 350 | 65 | 75 | 21 | |

| 2,50 | 10,40 | 350 | 65 | 75 | 21 | |

| 3,00 | 12,48 | 350 | 65 | 75 | 21 | |

| 3,50* | 14,56 | 350 | 65 | 75 | 21 | |

| Z 350 | 1,50 | 6,48 | 350 | 75 | 85 | 21 |

| 2,00 | 8,64 | 350 | 75 | 85 | 21 | |

| 2,50 | 10,80 | 350 | 75 | 85 | 21 | |

| 3,00 | 12,96 | 350 | 75 | 85 | 21 | |

| 3,50* | 15,20 | 350 | 75 | 85 | 21 | |

| Z 400 | 1,50 | 6,79 | 400 | 65 | 75 | 21 |

| 2,00 | 9,06 | 400 | 65 | 75 | 21 | |

| 2,50 | 11,32 | 400 | 65 | 75 | 21 | |

| 3,00 | 14,16 | 400 | 65 | 75 | 21 | |

| 3,50* | 15,84 | 400 | 65 | 75 | 21 | |

| Z 400 | 1,50 | 6,79 | 400 | 75 | 85 | 21 |

| 2,00 | 9,06 | 400 | 75 | 85 | 21 | |

| 2,50 | 11,32 | 400 | 75 | 85 | 21 | |

| 3,00 | 14,16 | 400 | 75 | 85 | 21 | |

| 3,50* | 16,52 | 400 | 75 | 85 | 21 | |

Holes

Z- and C-profiles enable industrial or service halls to be built up quickly and easily. They are mainly connected by screws. Three types of holes are provided in the profiles for this purpose (Table 1):

Table 1.

| Round holes (diameter – Ø w mm) |

Bean holes (lenght x width – in mm) |

|

|

|

|

|

|

|

|

|

|

|

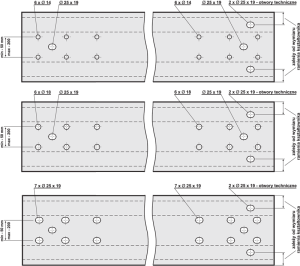

Depending on the type of profile used, there are different values for the technical-mounting hole spacing. Their values are given in the table below.

The figure shows longitudinal hole patterns.

Hole pattern is possible in all planes of the section.

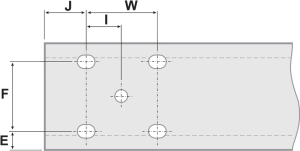

E – dimension from wide flange Bg (for type Z profiles)

Arrangement of holes

- J – 32 mm

- W – 100 mm

- I – 50 mm

| Profil Z | thickness | E | F |

|---|---|---|---|

| mm | mm | mm | |

| Z 100 | 1,5 | 25,8 | 50 |

| 2 | 26 | 50 | |

| 2,5 | 26,3 | 50 | |

| 3 | 26,5 | 50 | |

| Z 150 | 1,5 | 50,8 | 50 |

| 2 | 51 | 50 | |

| 2,5 | 51,3 | 50 | |

| 3 | 51,5 | 50 | |

| Z 180 | 1,5 | 50,8 | 80 |

| 2 | 51 | 80 | |

| 2,5 | 51,3 | 80 | |

| 3 | 51,5 | 80 | |

| Z 200 | 1,5 | 50,8 | 100 |

| 2 | 51 | 100 | |

| 2,5 | 51,3 | 100 | |

| 3 | 51,5 | 100 | |

| Z 250 | 1,5 | 50,8 | 150 |

| 2 | 51 | 150 | |

| 2,5 | 51,3 | 150 | |

| 3 | 51,5 | 150 | |

| Z 280 | 1,5 | 50,8 | 180 |

| 2 | 51 | 180 | |

| 2,5 | 51,3 | 180 | |

| 3 | 51,5 | 180 | |

| Z 300 | 1,5 | 50,8 | 200 |

| 2 | 51 | 200 | |

| 2,5 | 51,3 | 200 | |

| 3 | 51,5 | 200 | |

| Z 350 | 1,5 | 50,8 | 250 |

| 2 | 51 | 250 | |

| 2,5 | 51,3 | 250 | |

| 3 | 51,5 | 250 | |

| Z 400 | 1,5 | 50,8 | 300 |

| 2 | 51 | 300 | |

| 2,5 | 51,3 | 300 | |

| 3 | 51,5 | 300 | |

Types and distribution of holes

Recommendations

Transport recommendations

- In the case of collection by own means of transport, the vehicle should have an open loading platform to allow free loading and unloading.

Galvanised and aluzinc profiles must be protected against getting wet!

- In the case of collection by own means of transport, the vehicle should have an open loading platform to allow free loading and unloading.

Galvanised and aluzinc profiles must be protected against getting wet!

Storage recommendations

- Oil and passing galvanized sheets is a protection against white corrosion only during transport.

- Steps stored in packages cannot be stored in the open air or in rooms exposed to moisture and variable temperatures. Zinc and allusine coatings, in particular, not yet influenced by weather conditions, and therefore without a protective zone, are sensitive to water condensate with limited air access (sheet plate stored in packaging). Particular attention should be paid to unloading in winter conditions and storage in heated warehouses. As a result of a significant temperature difference between the sheets, water precipitates.

- Steps soaked during transport or storage should be dried, then put the profiles to spacers enabling free air circulation. After drying, galvanized (allusine) sections should be viewed and covered with a layer of preserving oil.

- Steel sheets intended for longer storage should be viewed and then covered with a layer of machine oil – for galvanized and allusine sheets.

- The result of not compliance with the above recommendations is the formation relatively quickly (for galvanized and allusine sheets it can be only a few days) of zinc corrosion – i.e. white, loosely related to the ground layers, not providing corrosion protection.

- Oil and passing galvanized sheets is a protection against white corrosion only during transport.

- Steps stored in packages cannot be stored in the open air or in rooms exposed to moisture and variable temperatures. Zinc and allusine coatings, in particular, not yet influenced by weather conditions, and therefore without a protective zone, are sensitive to water condensate with limited air access (sheet plate stored in packaging). Particular attention should be paid to unloading in winter conditions and storage in heated warehouses. As a result of a significant temperature difference between the sheets, water precipitates.

- Steps soaked during transport or storage should be dried, then put the profiles to spacers enabling free air circulation. After drying, galvanized (allusine) sections should be viewed and covered with a layer of preserving oil.

- Steel sheets intended for longer storage should be viewed and then covered with a layer of machine oil – for galvanized and allusine sheets.

- The result of not compliance with the above recommendations is the formation relatively quickly (for galvanized and allusine sheets it can be only a few days) of zinc corrosion – i.e. white, loosely related to the ground layers, not providing corrosion protection.

Color

Metallic coatings

Product description

Profiles Z

Cold -headed construction profiles of the Z, C and σ type are made of cold -plated steel.

The large variety of strength parameters of the sections allows you to optimally select the amount of material needed.